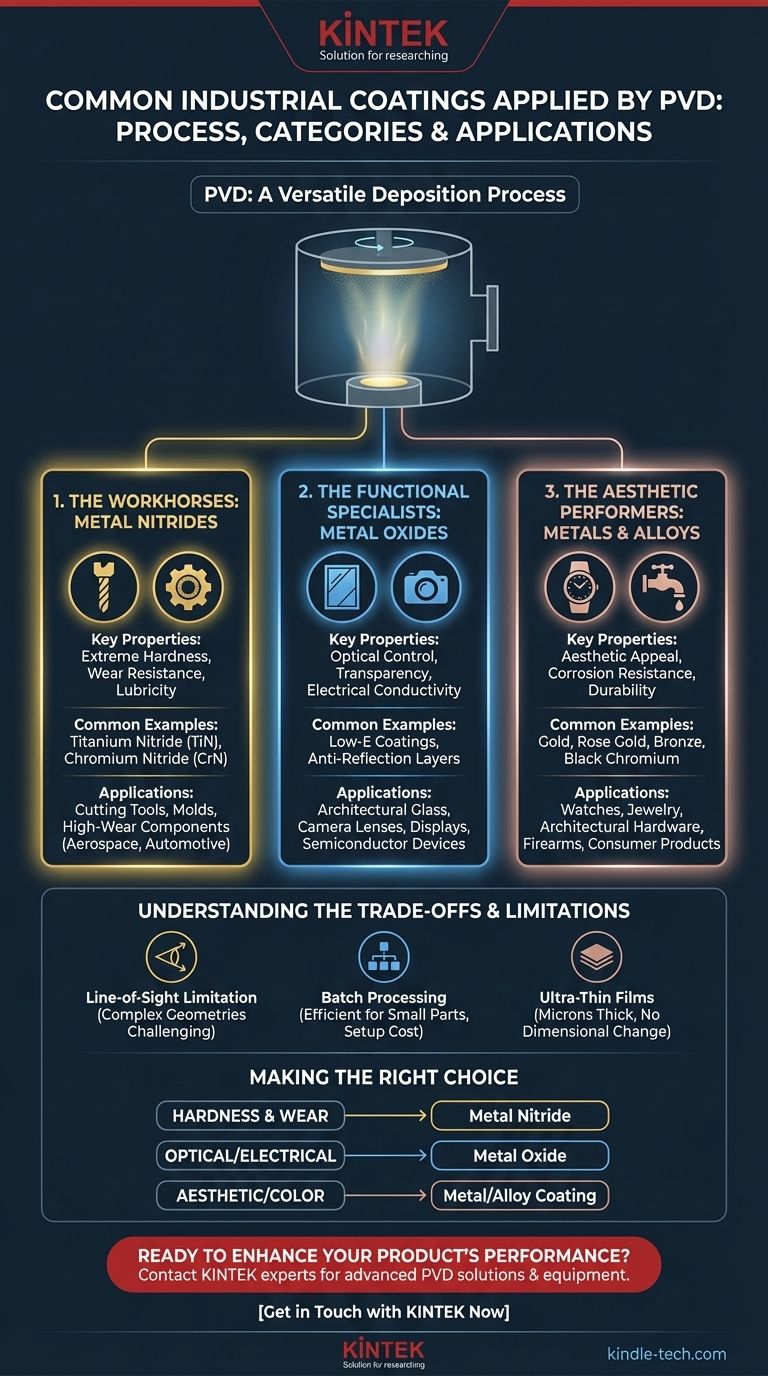

In short, the most common industrial coatings applied by Physical Vapor Deposition (PVD) fall into three main categories. These are hard-wearing metal nitrides (like Titanium Nitride), functional metal oxides used in optics and electronics, and a wide array of pure metals and alloys prized for their decorative or conductive properties.

The key is to understand that PVD is not a single coating, but a versatile deposition process. It allows engineers to apply an exceptionally thin, high-performance film of a specific material onto a substrate to achieve a desired property, whether that's extreme hardness, corrosion resistance, a specific color, or unique optical behavior.

The Primary Categories of PVD Coatings

PVD's versatility comes from the vast library of materials that can be deposited. These materials are chosen based on the functional requirements of the end product.

The Workhorses: Metal Nitrides

Metal nitrides are the cornerstone of PVD coatings for industrial tooling and high-wear components. They are valued for their exceptional hardness and lubricity.

Common examples include Titanium Nitride (TiN), known for its gold color and balanced properties, and Chromium Nitride (CrN), which offers superior corrosion resistance and is used in molds and dies.

The Functional Specialists: Metal Oxides

This category is crucial for advanced applications where light or electricity must be managed. These films are engineered for specific optical or conductive properties.

A prime example is low-emissivity (Low-E) coatings on architectural glass. These transparent metal oxide layers reflect thermal energy, keeping heat in during the winter and out during the summer, dramatically improving energy efficiency. Other uses include anti-reflection coatings on camera lenses and transparent conducting films for displays.

The Aesthetic Performers: Metals and Alloys

PVD is widely used to deposit thin layers of pure metals and alloys for both decorative and functional purposes. This method provides a durable finish that is far more resilient than traditional plating.

This includes coatings that produce gold, rose gold, bronze, gunmetal, and black finishes for applications like watches, jewelry, architectural hardware, and firearms. The process creates a strong molecular bond, ensuring the color won't easily chip, fade, or tarnish.

Where These Coatings Are Deployed

The choice of PVD coating is dictated entirely by the application's demands for performance, longevity, and appearance.

High-Wear and Tooling Applications

This is the classic industrial use for PVD. Coating cutting tools, drills, and molding dies with metal nitrides dramatically extends their operational life by reducing friction and resisting wear. A coated tool can often perform faster and longer than an uncoated one.

Aerospace and Automotive

In these industries, components require a combination of wear resistance, corrosion protection, and lubricity, often without adding significant weight or changing a part's dimensions. PVD provides an ultra-thin but highly durable film for critical engine components, bearings, and fasteners.

Architectural and Decorative Finishes

For items like faucets, door handles, and exterior panels, PVD provides a finish that is both beautiful and incredibly tough. Unlike paint or traditional plating, a PVD finish resists scratches, UV fading, and corrosion, making it ideal for high-touch surfaces.

Advanced Optics and Electronics

The precision of the PVD process is essential for high-tech applications. It allows for the deposition of atomic-level thin films required for semiconductor devices, optical filters, and anti-reflection coatings. The process occurs in a high-vacuum environment, ensuring the purity needed for these sensitive components.

Understanding the Trade-offs

While powerful, the PVD process has specific characteristics that make it suitable for some applications but not others.

The Line-of-Sight Limitation

PVD is a "line-of-sight" process. The coating material travels in a straight line from the source to the substrate. This makes it challenging to evenly coat parts with complex internal geometries or deep, narrow holes without sophisticated rotating fixtures.

Batch Processing and Cost

PVD is performed in a vacuum chamber, making it a batch process. While highly efficient for coating many small parts at once, the setup and cycle time can make it more costly than bulk finishing processes for very simple, low-value components. The performance benefit must justify the investment.

The Benefit of Thin Films

The coatings are exceptionally thin, often only a few microns (a fraction of the thickness of a human hair). This is a major advantage, as it adds critical surface properties without altering the part's underlying dimensions or mechanical strength.

Making the Right Choice for Your Goal

Selecting the correct PVD coating requires defining your primary objective.

- If your primary focus is maximizing hardness and wear resistance: A metal nitride coating like TiN or CrN is the standard choice for tools, molds, and mechanical components.

- If your primary focus is achieving a durable, specific color: A decorative metal or alloy coating is ideal for consumer products, watches, and architectural fixtures.

- If your primary focus is modifying optical or electrical properties: A specialized metal oxide or transparent conductive film is necessary for glass, lenses, and electronic components.

Ultimately, Physical Vapor Deposition provides a precise engineering tool to transform the surface of a product, ensuring it meets the highest demands of its intended application.

Summary Table:

| Coating Category | Common Examples | Key Properties | Typical Applications |

|---|---|---|---|

| Metal Nitrides | Titanium Nitride (TiN), Chromium Nitride (CrN) | Extreme Hardness, Wear Resistance, Lubricity | Cutting Tools, Molds, Industrial Tooling |

| Metal Oxides | Low-E Coatings, Anti-Reflection Layers | Optical Control, Transparency, Electrical Conductivity | Architectural Glass, Camera Lenses, Displays |

| Metals & Alloys | Gold, Rose Gold, Bronze, Black Chromium | Aesthetic Appeal, Corrosion Resistance, Durability | Watches, Jewelry, Architectural Hardware |

Ready to enhance your product's performance with a high-performance PVD coating?

At KINTEK, we specialize in providing advanced lab equipment and consumables for precise PVD processes. Whether you are developing cutting tools, durable decorative finishes, or advanced optical components, our solutions can help you achieve superior surface properties.

Contact our experts today to discuss how our PVD technology can bring durability, efficiency, and precision to your laboratory or production line. Let's find the perfect coating solution for your needs.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

People Also Ask

- What is the precursor gas in PECVD? The Key to Low-Temperature Thin Film Deposition

- What is the difference between thermal CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- Why is PECVD better than CVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the advantages of PECVD over CVD? Achieve High-Quality Thin Films at Lower Temperatures