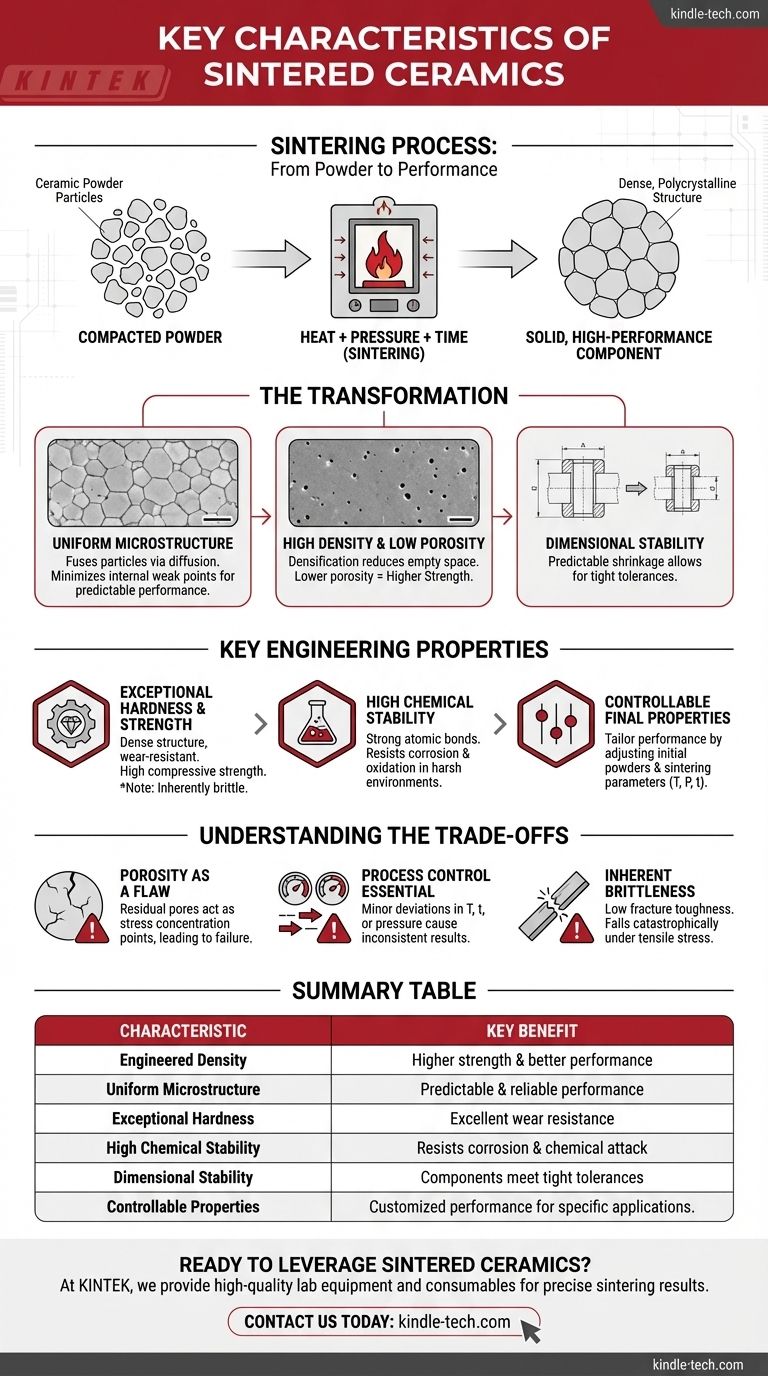

The most important characteristics of sintered ceramics are their engineered density, uniform microstructure, exceptional hardness, and high chemical stability. These properties are not inherent to the raw materials but are developed through the sintering process, which transforms a compacted powder into a solid, high-performance component.

Sintering is best understood as a precise engineering process, not just a heating step. It allows for the deliberate control of a material's final properties—like strength and density—by carefully managing the initial powder composition and the conditions of heat, time, and pressure.

The Transformation from Powder to Performance

Sintering is the critical manufacturing step that imparts value to ceramic components. It fundamentally changes the material's internal structure to achieve specific engineering goals.

Creating a Uniform Microstructure

The process fuses individual powder particles together through diffusion and mass transfer. This eliminates the gaps between them, creating a dense, polycrystalline (many-crystalled) material.

This resulting uniform microstructure is the foundation for predictable and reliable performance, as it minimizes internal weak points.

Achieving High Density and Low Porosity

A primary goal of sintering is densification, which means reducing the empty space, or porosity, within the material. The final porosity is a direct function of the initial powder compact, as well as the temperature and duration of the process.

Lower porosity almost always translates to higher strength and better overall performance. Applying pressure during sintering can significantly reduce both the time needed and the final porosity.

Ensuring Dimensional Stability

The sintering process consolidates the powder into a solid object with a stable and predictable shape. While some shrinkage occurs, it can be precisely calculated, allowing for the creation of components with tight dimensional tolerances required for advanced applications.

Key Engineering Properties of Sintered Ceramics

The unique microstructure created during sintering gives rise to a set of highly desirable material characteristics that are difficult to achieve with other materials.

Exceptional Hardness and Strength

The dense, unified structure of sintered ceramics makes them exceptionally hard and resistant to wear. This same structure provides high compressive strength, though it's important to recognize their inherent brittleness.

High Chemical Stability

The strong atomic bonds formed during the high-temperature sintering process result in excellent chemical stability. This makes the material highly resistant to corrosion, oxidation, and chemical attack, even in harsh environments.

Controllable Final Properties

One of the most powerful characteristics is that the final properties are highly controllable. Engineers can tailor the performance by adjusting the initial mix of powders and precisely managing the sintering parameters (temperature, time, pressure).

Understanding the Trade-offs

While powerful, the sintering process and the resulting materials have inherent challenges that must be managed for successful application.

Porosity as a Critical Flaw

While the goal is high density, achieving zero porosity is nearly impossible. Any residual pores can act as stress concentration points, becoming the origin of cracks and mechanical failure.

Process Control is Non-Negotiable

The final properties of a sintered ceramic are extremely sensitive to the process variables. Minor deviations in temperature, duration, or atmospheric conditions can lead to inconsistent density, grain size, and performance, making strict process control essential.

Inherent Brittleness

The same strong atomic bonds that create hardness and strength also result in low fracture toughness, or brittleness. Sintered ceramics typically fail catastrophically under tensile stress without plastic deformation, a critical design consideration.

Making the Right Choice for Your Application

The characteristics you prioritize will depend entirely on your end goal.

- If your primary focus is mechanical performance: Optimize for the lowest possible porosity by carefully controlling sintering temperature, pressure, and duration.

- If your primary focus is chemical resistance: Select high-purity initial powders, as impurities can become weak points that compromise chemical stability.

- If your primary focus is precision manufacturing: Characterize the shrinkage of your specific material and process to ensure the final component meets its required dimensional tolerances.

Understanding these core characteristics empowers you to engineer ceramic components for the most demanding technical challenges.

Summary Table:

| Characteristic | Description | Key Benefit |

|---|---|---|

| Engineered Density | Achieved by reducing porosity during sintering. | Higher strength and better performance. |

| Uniform Microstructure | Fused powder particles create a dense, polycrystalline material. | Predictable and reliable performance. |

| Exceptional Hardness | Dense, unified structure. | Excellent wear resistance. |

| High Chemical Stability | Strong atomic bonds formed at high temperatures. | Resists corrosion and chemical attack. |

| Dimensional Stability | Predictable shrinkage allows for precise manufacturing. | Components meet tight tolerances. |

| Controllable Properties | Tailored by adjusting powder mix and sintering parameters. | Customized performance for specific applications. |

Ready to leverage the superior properties of sintered ceramics for your laboratory applications?

At KINTEK, we specialize in providing the high-quality lab equipment and consumables necessary to achieve precise sintering results. Whether your focus is on maximizing mechanical performance, ensuring chemical resistance, or meeting strict dimensional tolerances, our expertise and products can help you engineer components for the most demanding challenges.

Contact us today via our contact form to discuss how we can support your specific laboratory needs and help you unlock the full potential of sintered ceramics.

Visual Guide

Related Products

- Precision Machined Silicon Nitride (SiN) Ceramic Sheet for Engineering Advanced Fine Ceramics

- Hexagonal Boron Nitride HBN Ceramic Ring

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

People Also Ask

- Which ceramic materials are most widely used? A Guide to Alumina, Zirconia, SiC, and Si3N4

- What are the factors affecting ceramic structure? From Atomic Charge to Final Properties

- What is SiC in refractory? Unlock Superior Performance for Extreme Heat & Abrasion

- What role does polyurethane foam play as a sacrificial template? Create Advanced Porous MgO Ceramics

- Is there anything better than a ceramic coating? Yes, for ultimate paint protection, combine PPF & ceramic coatings.

- How do ceramic insulators contribute to SHS experimental safety? Enhance Your Lab’s Ignition Precision and Protection

- What are the classification of ceramic materials? A Guide to Oxides, Non-Oxides, and Composites

- What kind of solid is SiC? Unlocking the Secrets of Its Covalent Network Structure