From a technical standpoint, flash pyrolysis offers significant advantages in processing speed and the yield of valuable products like bio-oil, making it highly efficient for converting biomass and waste. However, these benefits are balanced by considerable operational challenges, including high initial costs and the critical need to manage potentially harmful emissions through precise engineering and control.

Flash pyrolysis is not a silver bullet, but a specialized thermochemical tool. Its primary strength is maximizing the conversion of organic material into liquid bio-oil at high speed, but this efficiency demands significant investment and rigorous operational control to be both economically viable and environmentally sound.

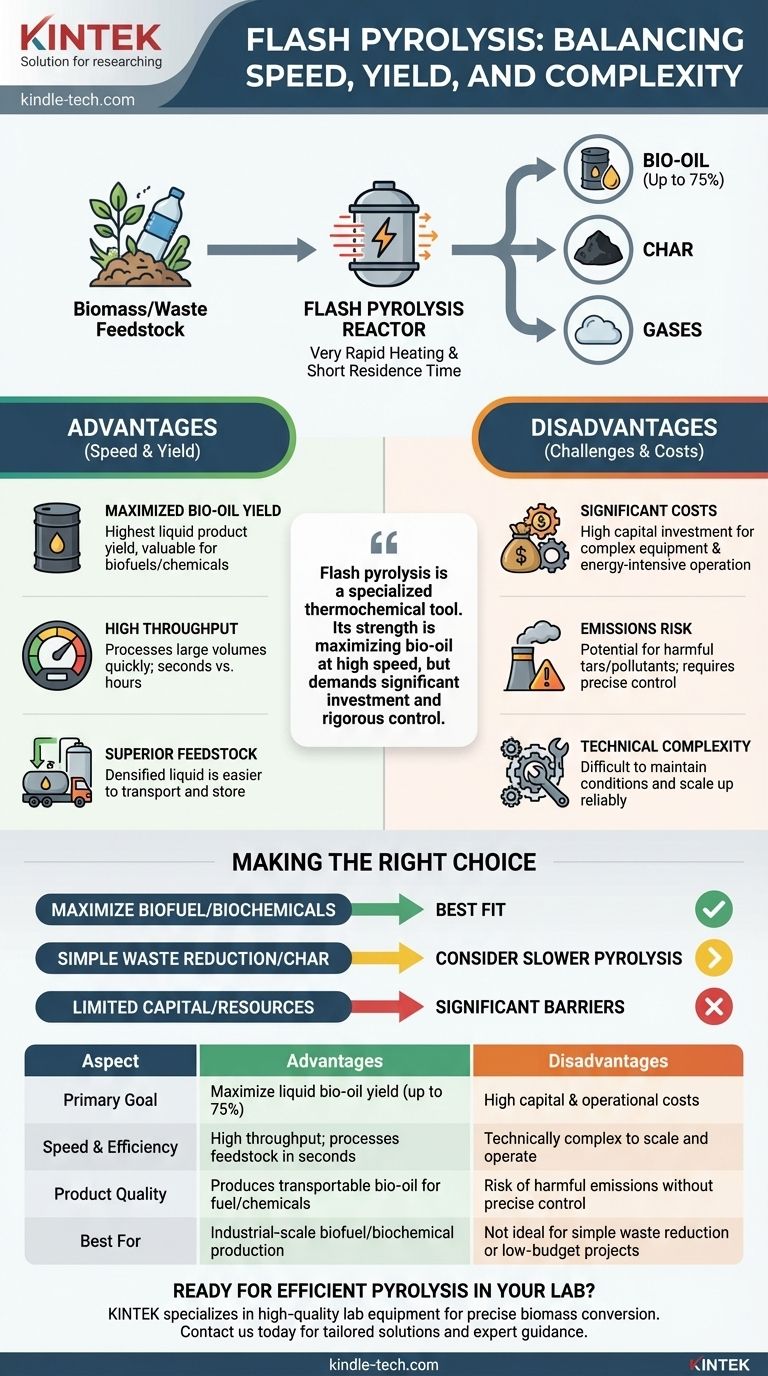

The Primary Advantages: Speed and Yield

Flash pyrolysis is a specific type of pyrolysis characterized by very rapid heating rates and short reaction times. This design is not accidental; it is engineered to achieve specific outcomes that differentiate it from slower pyrolysis methods.

Maximizing Bio-oil Production

The core advantage of flash pyrolysis is its ability to maximize the yield of liquid products, known as bio-oil or pyrolysis oil. The extremely fast heating breaks down organic materials like biomass or plastic so quickly that they don't have time to form excessive amounts of solid biochar or non-condensable gases (syngas).

This process typically yields up to 75% bio-oil by weight, compared to much lower liquid yields from slower pyrolysis processes which tend to produce more biochar.

High Throughput and Processing Speed

The "flash" nature of the process means that feedstock can be processed in seconds, rather than minutes or hours. This allows a flash pyrolysis reactor to handle a much larger volume of material over time compared to a conventional pyrolysis reactor of a similar size.

This high throughput is a critical factor for industrial-scale operations where processing large quantities of waste or biomass is a key economic driver.

Creating a Superior Feedstock

The bio-oil produced through flash pyrolysis can serve as a valuable intermediate product. It can be upgraded into transportation biofuels, used to generate heat and power, or serve as a source for extracting valuable specialty chemicals.

Its liquid form makes it easier to transport and store than raw solid biomass, effectively densifying the energy and value of the original material.

Understanding the Trade-offs and Inherent Challenges

The high performance of flash pyrolysis comes with a set of significant challenges that must be addressed for successful implementation. Ignoring these trade-offs is a common cause of project failure.

Significant Capital and Operating Costs

Achieving rapid heating and precise temperature control requires sophisticated and expensive equipment. The reactors, feedstock preparation systems, and quenching equipment needed to capture the bio-oil vapor represent a high upfront capital investment.

Furthermore, operating at high temperatures is energy-intensive, leading to high operational costs that must be factored into the economic model.

The Critical Emissions Risk

Like all high-temperature processes, pyrolysis carries the risk of producing harmful emissions if not managed perfectly. The lack of oxygen prevents combustion but can lead to the formation of pollutants like tars, particulate matter, and volatile organic compounds.

Proper furnace design, robust operational protocols, and effective maintenance are not optional—they are essential to minimize environmental impact and comply with air quality regulations.

Technical Complexity and Scaling Hurdles

Maintaining the ideal conditions for flash pyrolysis—extremely high heat transfer rates and short vapor residence times—is an engineering challenge. These conditions are difficult to maintain consistently, especially when scaling the process up from a laboratory or pilot plant to a full-scale industrial facility.

Technical issues with feeding systems, heat transfer, and product collection can hinder efficiency and reliability.

Making the Right Choice for Your Goal

To determine if flash pyrolysis is the correct approach, you must align its specific capabilities with your primary objective.

- If your primary focus is maximizing liquid biofuel or biochemical production from biomass: Flash pyrolysis is the most effective technology due to its engineered design for high bio-oil yields.

- If your primary focus is simple waste volume reduction or maximizing solid biochar output: A slower, less complex pyrolysis process is often more cost-effective and operationally simpler.

- If your primary focus is a project with limited capital or technical resources: The high initial investment and engineering complexity of flash pyrolysis may present significant barriers to success.

Ultimately, success with flash pyrolysis depends on a clear-eyed assessment of its trade-offs and a firm commitment to the engineering precision it demands.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Primary Goal | Maximize liquid bio-oil yield (up to 75%) | High capital and operational costs |

| Speed & Efficiency | High throughput; processes feedstock in seconds | Technically complex to scale and operate |

| Product Quality | Produces transportable bio-oil for fuel/chemicals | Risk of harmful emissions without precise control |

| Best For | Industrial-scale biofuel/biochemical production | Not ideal for simple waste reduction or low-budget projects |

Ready to implement an efficient pyrolysis solution for your lab?

At KINTEK, we specialize in providing high-quality lab equipment, including pyrolysis systems, to help you achieve precise and reliable results in biomass conversion and waste processing. Our expertise ensures you get the right tools to maximize yield while managing operational challenges effectively.

Contact us today to discuss your specific needs and discover how KINTEK can support your research and development goals with tailored solutions and expert guidance.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- Why is sintering important in ceramic processing? Achieve Dense, High-Performance Ceramic Parts

- How is the ash content determined in a muffle furnace? Master the Gravimetric Analysis Method

- What is the burnout cycle on a furnace? Stop This Destructive Overheating Pattern Now

- Which gas is used in a muffle furnace? Choosing the Right Atmosphere for Your Lab Process

- What is done by ashing in muffle furnace? A Guide to Precise Inorganic Content Analysis