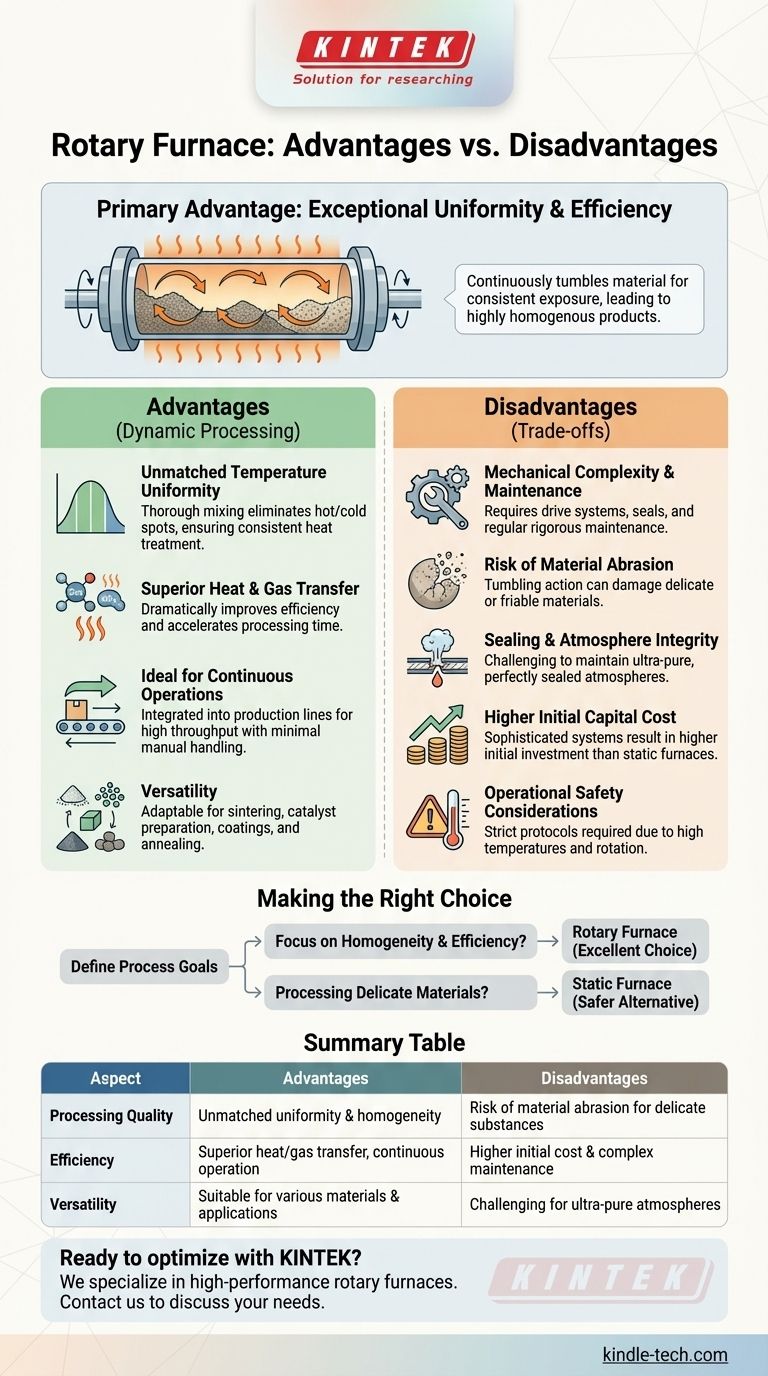

The primary advantage of a rotary furnace is its ability to process materials with exceptional uniformity and efficiency. By continuously tumbling the material in a heated, rotating tube, it ensures every particle is consistently exposed to the desired temperature and atmospheric conditions, leading to a highly homogenous end product.

A rotary furnace excels at producing consistent materials through dynamic mixing and efficient heat transfer. However, this operational advantage comes with the trade-off of greater mechanical complexity, potential for material abrasion, and more stringent sealing requirements compared to static furnace designs.

The Core Advantages of Dynamic Processing

The unique rotational design of these furnaces provides several distinct benefits over static alternatives. These advantages stem from the fundamental principle of keeping the material in constant, gentle motion during the thermal cycle.

Unmatched Temperature Uniformity

The continuous rotation and tumbling action forces the material to mix thoroughly. This eliminates localized hot or cold spots, preventing temperature gradients within the batch and ensuring a highly consistent heat treatment for every particle.

Superior Heat and Gas Transfer

By constantly exposing the entire surface area of the material, a rotary furnace dramatically improves efficiency. This enhances the diffusion of process gases into the material and accelerates heat transfer, often reducing overall processing time and gas consumption.

Ideal for Continuous Operations

Rotary furnaces are engineered for continuous material flow. They can be integrated into production lines where raw material is fed into one end and the processed product is discharged from the other, minimizing manual handling and improving throughput for large batches.

Versatility Across Materials and Applications

This technology is highly adaptable, capable of processing materials ranging from fine powders and granules to larger solids. It is widely used for applications like sintering ceramic and metal powders, preparing catalysts, creating surface coatings, and annealing metal components.

Understanding the Trade-offs and Disadvantages

While powerful, the rotary furnace design is not universally optimal. Its advantages come with inherent complexities and limitations that must be considered.

Mechanical Complexity and Maintenance

The rotational motion requires a drive system, bearings, and, most critically, robust seals. These moving parts introduce more potential points of failure and require a more rigorous maintenance schedule compared to a simpler static furnace.

Risk of Material Abrasion

The tumbling action that ensures uniformity can also be a disadvantage. For delicate, brittle, or friable materials, this mechanical movement can cause particles to break down, create unwanted dust, or damage the product's structure.

Sealing and Atmosphere Integrity

Maintaining a perfectly controlled, high-purity atmosphere can be more challenging in a rotary furnace. The dynamic seals at the ends of the rotating tube must be robustly engineered to prevent leaks, which is a more complex task than sealing a static chamber.

Higher Initial Capital Cost

The sophisticated mechanical systems, including the drive, tube, and sealing components, typically result in a higher initial purchase price than a static box or tube furnace of similar capacity.

Operational Safety Considerations

The combination of high temperatures, rotation, and potential pressure buildup requires strict adherence to safety protocols. Improper operation can lead to equipment damage or hazardous situations, demanding well-trained personnel.

Making the Right Choice for Your Process

Selecting the correct furnace technology requires a clear understanding of your material, your process goals, and your operational constraints.

- If your primary focus is product homogeneity and efficiency: A rotary furnace is an excellent choice, particularly for continuous processing of powdered or granular materials that benefit from mixing.

- If you are processing delicate or abrasion-sensitive materials: Carefully evaluate if the tumbling action will degrade your product; a static furnace may be a safer alternative.

- If your process requires an ultra-pure, perfectly sealed atmosphere: Scrutinize the furnace's sealing technology, as maintaining atmospheric integrity is inherently more challenging than in a static system.

- If budget and maintenance simplicity are top priorities: A static furnace offers a simpler, often more cost-effective solution, provided it can meet your quality standards.

Ultimately, choosing a rotary furnace is a strategic decision that trades higher mechanical complexity for unparalleled uniformity and efficiency in thermal processing.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Processing Quality | Unmatched temperature uniformity and product homogeneity | Risk of material abrasion for delicate or friable substances |

| Efficiency | Superior heat and gas transfer; ideal for continuous operations | Higher initial capital cost and more complex maintenance |

| Versatility | Suitable for powders, granules, and various thermal applications | Challenging to maintain ultra-pure, perfectly sealed atmospheres |

Ready to optimize your thermal processing with a rotary furnace? KINTEK specializes in high-performance lab equipment, including rotary furnaces designed for superior uniformity and efficiency. Whether you're sintering ceramics, preparing catalysts, or annealing metals, our solutions ensure consistent results and enhanced productivity. Contact us today to discuss your specific laboratory needs and discover how KINTEK can empower your research and production processes!

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What is a rotary retort furnace? Achieve Superior Uniformity in Continuous Heat Treatment

- What is the process of zirconium production? From Ore to High-Performance Metal & Ceramic

- Why is a high-temperature furnace with multi-probe testing used for ABO3 perovskite? Get Precise Conductivity Data

- What is the temperature of a rotary hearth furnace? Find the Right Heat for Your Process

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity