The primary advantages of carbon nanotubes are their unparalleled combination of exceptional mechanical strength, superior electrical conductivity, and high thermal stability, all contained within a lightweight, high-aspect-ratio structure. This unique blend of properties allows them to act as powerful multifunctional additives, significantly enhancing the performance of other materials, most notably in lithium-ion batteries and advanced composites.

The true power of carbon nanotubes isn't just one superlative property, but their ability to simultaneously improve multiple characteristics—strength, conductivity, and durability—when integrated into a host material. This makes them less of a simple ingredient and more of a comprehensive performance upgrade.

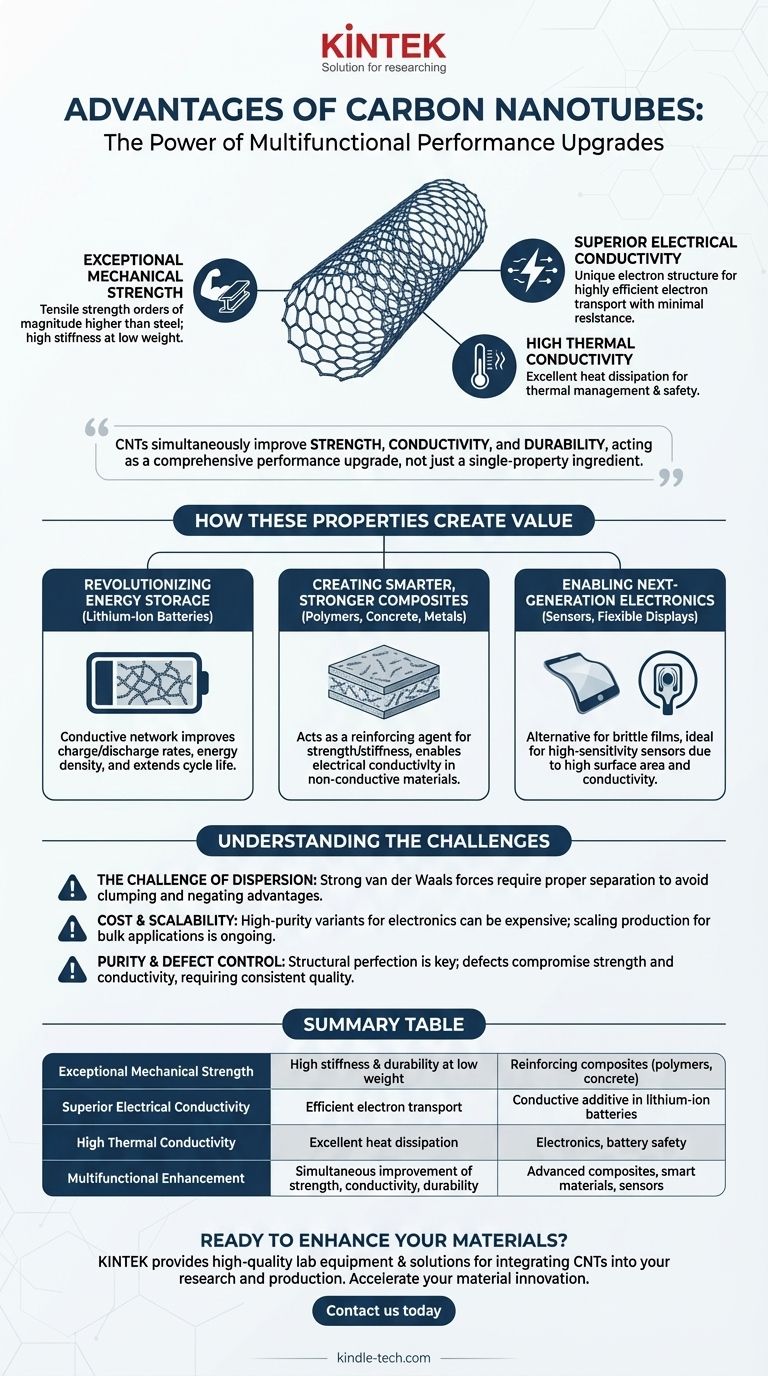

Unpacking the Core Properties of CNTs

To understand the applications of carbon nanotubes (CNTs), we must first understand their three foundational advantages. These properties originate from their unique structure: a seamless, cylindrical lattice of carbon atoms.

Exceptional Mechanical Strength

CNTs are one of the strongest and stiffest materials yet discovered. Their tensile strength can be orders of magnitude higher than that of steel, at a fraction of the weight.

This strength comes from the powerful covalent bonds between carbon atoms. Imagine a perfectly woven rope at the nanoscale, where every atom is locked into an ideal position, creating a structure with very few defects to act as weak points.

Superior Electrical Conductivity

The unique electron structure of carbon nanotubes allows them to be highly conductive. Electrons can flow easily along the length of the tube with very little resistance.

This property is a primary reason for their widespread use as a conductive additive. A very small amount of CNTs can form a pervasive electrical network within a non-conductive material, like the active materials in a battery electrode.

High Thermal Conductivity

In addition to conducting electricity, CNTs are also excellent conductors of heat. They can efficiently dissipate thermal energy, which is a critical function in many electronic and high-performance applications.

This ability to manage heat helps improve the safety and lifespan of devices like batteries and protects sensitive electronic components from overheating.

How These Properties Create Value

These fundamental advantages are not merely academic. They translate directly into tangible improvements across a wide range of critical applications, from green technology to industrial materials.

Revolutionizing Energy Storage

The most significant commercial application for CNTs today is in lithium-ion batteries. They solve a key problem by creating a conductive network between active material particles in both the cathode and anode.

This network improves the battery's charge and discharge rates, increases its energy density, and extends its cycle life by holding the electrode materials together more robustly over time.

Creating Smarter, Stronger Composites

When dispersed into polymers, concrete, or metals, CNTs act as a reinforcing agent. They can drastically increase the strength and stiffness of the host material with minimal weight gain.

Simultaneously, their conductivity can transform an insulating material like plastic into one that is electrically conductive or anti-static, a critical feature for applications in electronics, automotive, and aerospace.

Enabling Next-Generation Electronics

CNTs are being explored for use in transparent conductive films, which are essential for touch screens and flexible displays. They offer a more durable and flexible alternative to the brittle indium tin oxide (ITO) used today.

Their high surface area and conductivity also make them ideal for creating highly sensitive chemical and biological sensors.

Understanding the Trade-offs and Challenges

While their properties are remarkable, realizing the full potential of CNTs is not without technical hurdles. Objectivity requires acknowledging these limitations.

The Challenge of Dispersion

By nature, CNTs have a strong tendency to clump together due to van der Waals forces. If they are not properly separated and dispersed within a host material, their advantages are completely negated. Achieving uniform dispersion is a critical and often difficult manufacturing step.

Cost and Scalability

While the cost of CNTs has decreased significantly, high-purity variants required for sensitive electronic applications can still be expensive. Scaling up production to meet demand for bulk applications like concrete or asphalt remains an ongoing process for the industry.

Purity and Defect Control

The incredible properties of CNTs are highly dependent on their structural perfection. Defects in the nanotube wall can compromise their strength and conductivity. Ensuring consistent quality and purity at an industrial scale is essential for predictable performance.

Making the Right Choice for Your Application

The "best" advantage of carbon nanotubes depends entirely on the problem you are trying to solve. Your specific goal will determine which property you leverage most.

- If your primary focus is energy storage (e.g., batteries): The key advantage is superior electrical conductivity, which creates efficient pathways for electrons to improve power density and cycle life.

- If your primary focus is material science (e.g., composites): The key advantage is multifunctional enhancement, where a single additive provides both mechanical reinforcement and electrical conductivity.

- If your primary focus is advanced electronics (e.g., sensors or films): The key advantage is the unique combination of conductivity, high surface area, and potential transparency, enabling novel device designs.

Ultimately, understanding the core advantages of CNTs allows you to use them not as a brute-force ingredient, but as a precision tool for targeted material innovation.

Summary Table:

| Key Advantage | Primary Benefit | Key Application |

|---|---|---|

| Exceptional Mechanical Strength | High stiffness & durability at low weight | Reinforcing composites (polymers, concrete) |

| Superior Electrical Conductivity | Efficient electron transport with minimal resistance | Conductive additive in lithium-ion batteries |

| High Thermal Conductivity | Excellent heat dissipation & thermal management | Electronics, battery safety, high-performance materials |

| Multifunctional Enhancement | Simultaneously improves strength, conductivity, and durability | Advanced composites, smart materials, sensors |

Ready to enhance your materials with the power of carbon nanotubes?

KINTEK specializes in providing high-quality lab equipment and consumables for advanced material development, including solutions for integrating CNTs into your research and production processes. Whether you're developing next-generation batteries, stronger composites, or innovative electronic devices, our expertise can help you achieve superior performance and efficiency.

Contact us today to discuss how we can support your laboratory's specific needs and accelerate your material innovation journey.

Visual Guide

Related Products

- Boron Nitride (BN) Ceramic Tube

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

- Multi-zone Laboratory Tube Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- High-Purity Titanium Foil and Sheet for Industrial Applications

People Also Ask

- What is a potential application for the nanotubes? Boost Performance in Batteries, Composites & Electronics

- What are the advantages of thin film deposition? Unlock New Material Properties and Efficiency

- What is an example of sputtering? Creating Anti-Reflective Coatings and Advanced Materials

- Is carbon nanotube an electrical conductor? Its dual nature depends on atomic structure.

- Can graphene be made artificially? A Guide to Synthesis Methods for Your Application

- What are 4 applications of carbon nanotubes? Enhancing Batteries, Composites, Electronics & Sensors

- Why are thin films useful? Unlock New Material Properties with Surface Engineering

- What are the applications of thin-film in renewable energy? Beyond Solar Panels to Energy Storage & Hydrogen