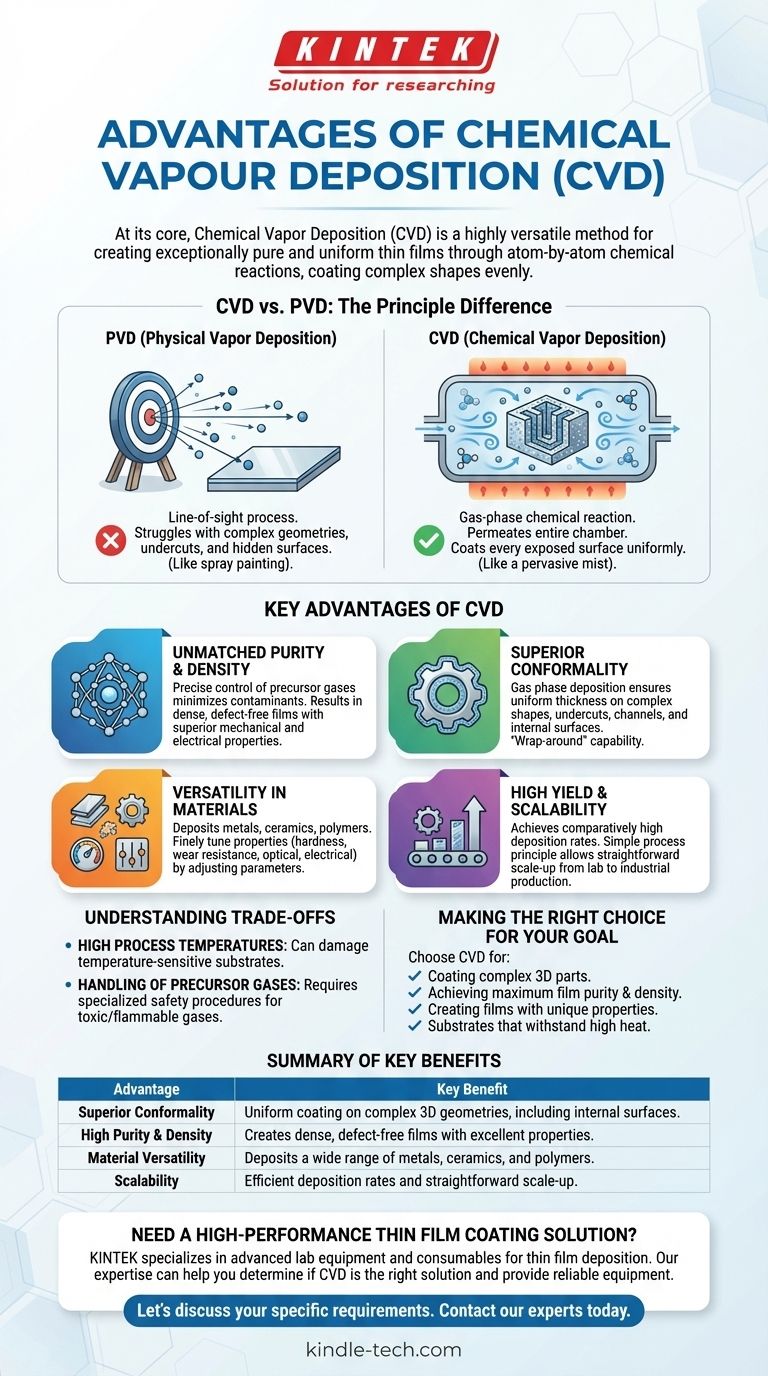

At its core, Chemical Vapor Deposition (CVD) is a highly versatile method for creating exceptionally pure and uniform thin films. Its primary advantages stem from its unique process, which uses chemical reactions to deposit material atom-by-atom onto a surface, allowing it to coat complex shapes evenly and produce a wide range of materials with precisely controlled properties.

Choosing a deposition technique is a critical engineering decision. While many methods exist, Chemical Vapor Deposition stands out for its ability to create highly pure and conformal coatings, making it the superior choice for applications where material quality and complete, even coverage are non-negotiable.

The Principle: Chemical Reaction vs. Physical Deposition

To understand the advantages of CVD, it is essential to distinguish it from its main alternative, Physical Vapor Deposition (PVD).

How PVD Works

PVD methods like sputtering or evaporation are "line-of-sight" processes. They physically knock atoms off a solid target in a vacuum and send them flying toward the substrate, much like a spray paint can coating a surface.

This physical transfer means PVD can struggle to evenly coat the hidden surfaces or intricate internal features of a complex object.

How CVD Works

CVD is fundamentally different. It introduces precursor gases into a chamber containing a heated substrate. A chemical reaction is triggered on the hot surface, causing a solid material to "grow" or deposit onto the substrate.

Because this process is driven by a gas that fills the entire chamber, it is not limited by line-of-sight. The reactive gas can reach every exposed surface, no matter how complex the part's geometry.

Key Advantages of the CVD Method

The chemical nature of the CVD process gives rise to several distinct advantages that are difficult to achieve with other techniques.

Unmatched Film Purity and Density

The CVD process allows for the creation of films with an extremely high degree of purity. By precisely controlling the input precursor gases, contaminants can be minimized.

This results in a very dense and uniform film structure with low residual stress and good crystallization, leading to superior mechanical and electrical properties.

Superior Conformality on Complex Geometries

This is perhaps CVD's most significant advantage. Because the deposition occurs from a gas phase that permeates the entire reaction chamber, CVD provides an exceptionally conformal coating.

This "wrap-around" capability ensures that even complex shapes with undercuts, channels, or internal surfaces receive a coating of uniform thickness. PVD methods simply cannot match this.

Versatility in Materials and Properties

CVD can be used to deposit a vast range of materials, including metals, ceramics, and polymers. By adjusting the precursor gases, temperature, and pressure, the properties of the final film can be finely tuned.

This allows for the creation of films with specific, high-performance characteristics, such as extreme hardness, wear resistance, or unique optical and electrical properties that are difficult to obtain otherwise.

High Yield and Scalability for Production

CVD processes can achieve comparatively high deposition rates, making them efficient for manufacturing.

Furthermore, the equipment is often simple in principle, making the process relatively straightforward to scale up from laboratory research to high-volume industrial production.

Understanding the Trade-offs

No method is perfect. The strengths of CVD are balanced by certain operational considerations.

High Process Temperatures

Traditional CVD processes often require high temperatures (hundreds or even thousands of degrees Celsius) to initiate the necessary chemical reactions on the substrate's surface.

This high heat can be a limitation, as it may damage or alter the properties of temperature-sensitive substrates, such as certain polymers or pre-processed semiconductor wafers.

Handling of Precursor Gases

The precursor gases used in CVD can be toxic, corrosive, or flammable, requiring specialized handling procedures and safety infrastructure.

This adds a layer of complexity and cost to the operation compared to some PVD methods that use inert solid targets.

Making the Right Choice for Your Goal

Selecting CVD depends entirely on your project's specific requirements.

- If your primary focus is coating a complex 3D part: CVD is the superior choice due to its outstanding conformal coverage.

- If your primary focus is achieving maximum film purity and density: CVD offers precise chemical control that is ideal for producing high-quality, defect-free materials.

- If your primary focus is creating a film with unique stoichiometry or hardness: CVD's versatility in material synthesis allows for engineering specific and high-performance coatings.

- If your primary focus is coating a temperature-sensitive material: You must carefully evaluate if the substrate can withstand the heat of a standard CVD process or if a lower-temperature variant (like PECVD) or an alternative like PVD is required.

Understanding the fundamental difference between chemical and physical deposition empowers you to select the right tool for your specific engineering challenge.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Superior Conformality | Uniform coating on complex 3D geometries, including internal surfaces and undercuts. |

| High Purity & Density | Creates dense, defect-free films with excellent mechanical and electrical properties. |

| Material Versatility | Deposits a wide range of metals, ceramics, and polymers with tunable properties. |

| Scalability | Efficient deposition rates and straightforward scale-up for high-volume production. |

Need a High-Performance Thin Film Coating Solution?

Chemical Vapor Deposition is the ideal choice when your project demands exceptional film purity, uniform coverage on complex parts, and tailored material properties.

KINTEK specializes in advanced lab equipment and consumables for thin film deposition, serving the precise needs of research and industrial laboratories. Our expertise can help you determine if CVD is the right solution for your application and provide the reliable equipment you need to succeed.

Let's discuss your specific requirements. Contact our experts today to explore how our solutions can enhance your research or production process.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques