In the field of thin-film coatings, electron beam (E-Beam) deposition is a widely used physical vapor deposition (PVD) method valued for its high speed and flexibility. Its primary advantages are its rapid processing time for batch production, its compatibility with a wide and inexpensive range of materials, and its fundamental simplicity, making it a cornerstone of high-volume commercial applications like optical coatings.

Electron beam deposition excels at rapidly and cost-effectively coating substrates. While its standard form offers unmatched versatility, its true potential for creating high-performance, durable films is often unlocked when enhanced with an ion-assist process.

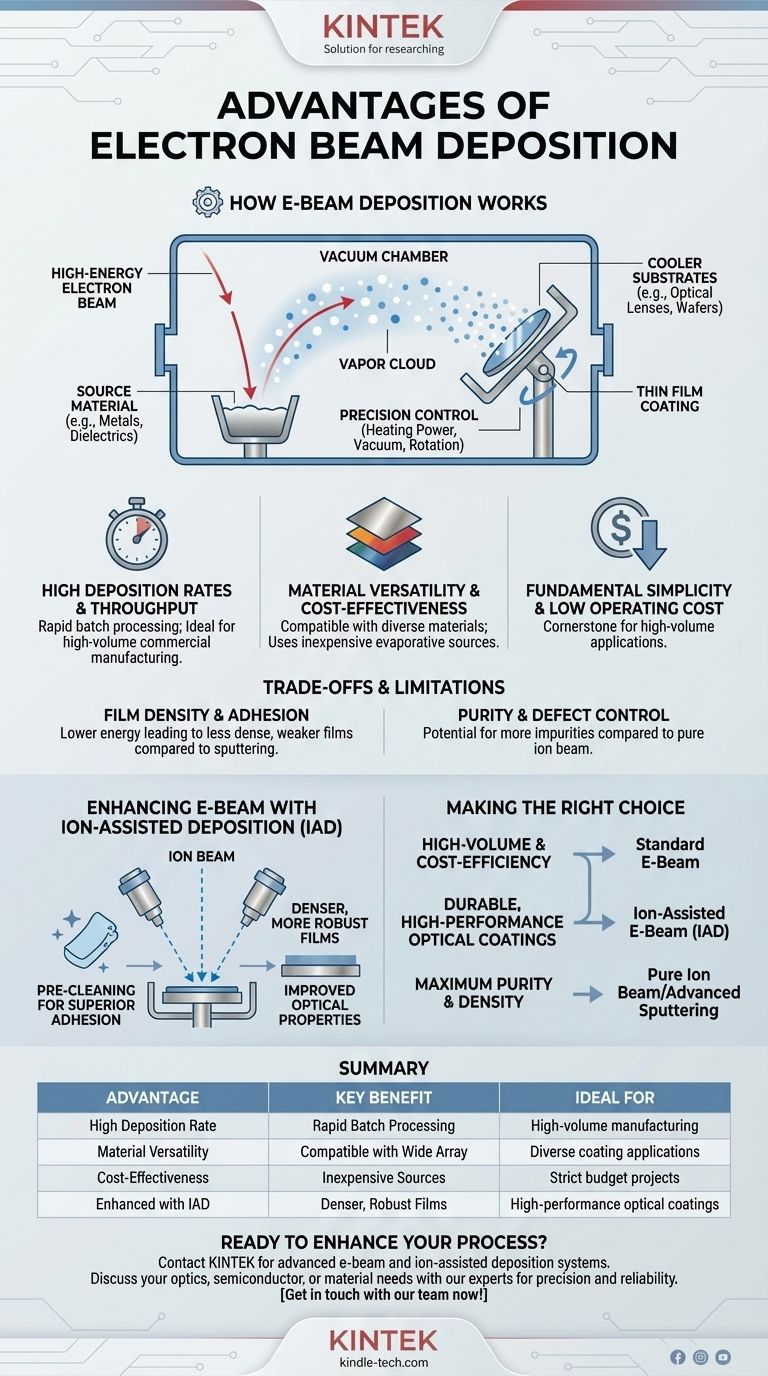

How Electron Beam Deposition Works

To understand its advantages, it is first necessary to understand the core process. E-Beam deposition is a relatively straightforward PVD technique that takes place inside a vacuum chamber.

The Source Material and Beam

The process begins with the source material—often in powder or granular form—held in a crucible. A high-energy beam of electrons is generated and magnetically guided to strike this source material.

Vaporization and Condensation

The intense energy from the electron beam heats the material, causing it to evaporate or sublimate into a vapor. This vapor cloud then travels through the vacuum chamber and condenses onto the cooler substrates, such as optical lenses or semiconductor wafers, forming a thin film.

Precision Control

Through precise computer control of the heating power, vacuum level, and substrate rotation, operators can achieve highly uniform coatings of a specified thickness across multiple substrates at once.

Core Advantages of the E-Beam Process

The inherent mechanics of E-Beam deposition give it several key advantages over competing technologies like magnetron sputtering.

High Deposition Rates and Throughput

E-Beam deposition can evaporate materials much faster than sputtering. This makes it ideal for rapidly processing large batches of parts, significantly increasing throughput for high-volume commercial manufacturing.

Material Versatility and Cost-Effectiveness

The process is compatible with a vast array of materials, including metals and dielectric compounds. Crucially, it uses relatively inexpensive evaporative source materials, whereas the sputter targets required for magnetron sputtering are traditionally more complex and costly to manufacture.

Understanding the Trade-offs and Limitations

No single technology is perfect. The primary advantages of E-Beam in speed and cost come with trade-offs in film quality that must be understood. Standard E-Beam films can sometimes fall short of the performance achieved by slower, more energetic processes.

Film Density and Adhesion

The relatively low energy of the vaporized atoms in standard E-Beam deposition can result in films that are less dense and have weaker adhesion compared to those produced by sputtering. This can create films that are less robust or have higher internal stress.

Purity and Defect Control

While effective, the process can sometimes introduce more impurities or structural defects into the film compared to highly controlled methods like ion beam deposition, which is known for producing exceptionally pure films.

Enhancing E-Beam: The Role of Ion-Assisted Deposition (IAD)

To overcome the inherent limitations of the standard process, E-Beam is often enhanced with a secondary ion beam in a hybrid process known as ion-assisted deposition (IAD).

Pre-Cleaning for Superior Adhesion

In an IAD setup, an ion beam bombards the substrate surface before deposition begins. This acts as an atomic-level cleaning process, removing contaminants and increasing the surface energy, which dramatically improves the adhesion of the subsequent film.

Creating Denser, More Robust Films

The ion beam can also be used during deposition. This continuous bombardment adds energy to the growing film, compacting the atoms together. The result is a denser, more robust, and more stable coating with lower internal stress and improved optical properties.

Making the Right Choice for Your Application

Selecting a deposition method requires aligning the technology's strengths with your project's primary goal.

- If your primary focus is high-volume production and cost-efficiency: Standard E-Beam deposition is an excellent choice due to its high deposition rates and use of inexpensive source materials.

- If your primary focus is creating durable, high-performance optical coatings: Ion-assisted E-Beam (IAD) is the superior method, as it combines the speed of E-Beam with the film quality benefits of ion bombardment.

- If your primary focus is achieving maximum film purity and density above all else: Pure ion beam deposition or advanced sputtering techniques may be worth evaluating, though often at the cost of speed and throughput.

By understanding these capabilities and trade-offs, you can select and configure the right deposition process to meet your specific performance and budget targets.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| High Deposition Rate | Rapidly processes large batches of parts | High-volume commercial manufacturing |

| Material Versatility | Compatible with a wide array of materials (metals, dielectrics) | Applications requiring diverse coating materials |

| Cost-Effectiveness | Uses relatively inexpensive source materials | Projects with strict budget constraints |

| Enhanced with IAD | Ion-assisted deposition creates denser, more robust films | High-performance, durable optical coatings |

Ready to enhance your thin-film coating process?

Electron beam deposition is a powerful tool for achieving high-throughput, cost-effective coatings. At KINTEK, we specialize in providing advanced laboratory equipment, including e-beam and ion-assisted deposition systems, to meet the demanding needs of research and production labs.

Our experts can help you select the right configuration to balance speed, cost, and film performance for your specific application—whether it's for optics, semiconductors, or other advanced materials.

Contact us today to discuss how our solutions can bring precision, efficiency, and reliability to your lab. Get in touch with our team now!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is the process of thermal evaporation? A Guide to Simple, Cost-Effective Thin-Film Deposition

- What are thin films deposited by evaporation? A Guide to High-Purity Coating

- What are the major differences between thermal evaporation and electron beam evaporation? Choose the Right PVD Method

- What is the difference between thermal evaporation and magnetron sputtering? Choose the Right PVD Coating Method

- What is thermal evaporation of thin film deposition? A Simple Guide to PVD Coating

- What is evaporation in thin film? A Guide to High-Purity Coating with PVD

- What is the meaning of thermal evaporation? A Guide to Simple, Cost-Effective Thin Film Coating

- What is the deposition rate of thermal evaporation? Master the Key Variables for Your Thin Films