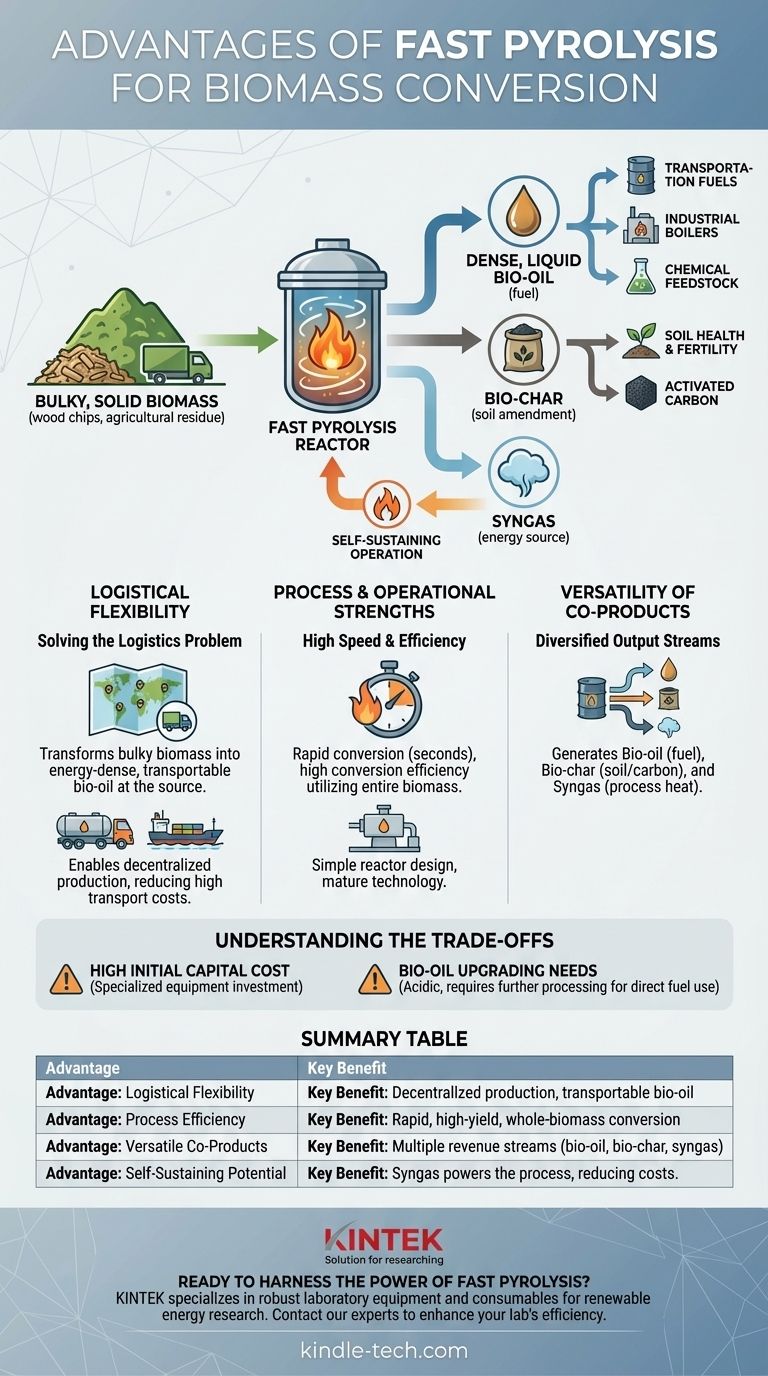

At its core, fast pyrolysis offers a rapid and efficient method for converting bulky, solid biomass into a dense, liquid fuel. Its primary advantages lie in logistical flexibility, process efficiency, and the versatility of its products, making it a key technology for decentralized energy production.

The central challenge with biomass is its low energy density and high transport cost. Fast pyrolysis solves this by converting the solid biomass into an energy-dense, easily transportable liquid—bio-oil—right at the source, fundamentally changing the economics of biomass utilization.

The Core Advantage: Solving the Logistics Problem

The most significant benefit of fast pyrolysis is its ability to overcome the logistical hurdles associated with biomass. Raw biomass (like wood chips or crop residues) is bulky and expensive to transport over long distances.

Transforming Bulky Biomass into Liquid Fuel

Fast pyrolysis converts solid biomass into a liquid bio-oil. This liquid is far more energy-dense and easier to handle, store, and transport than the original solid feedstock.

This conversion dramatically reduces transportation costs, as the valuable energy can be moved more efficiently, similar to how crude oil is transported.

Enabling a Decentralized Production Model

Because pyrolysis reactors can be built on a relatively small and even mobile scale, they can be deployed directly at or near the source of the biomass.

This decentralized approach minimizes the costly transport of raw materials. Instead of hauling truckloads of wood chips to a central plant, a mobile unit can process them on-site, producing a smaller volume of high-value bio-oil for transport to a central refinery or user.

Process and Operational Strengths

Beyond logistics, the process itself has several inherent advantages that make it a feasible and attractive technology.

High Speed and Simplicity

As the name suggests, the process is extremely fast, taking only a few seconds. The reactors themselves are relatively simple in design and have achieved a level of commercial maturity.

High Conversion Efficiency

Fast pyrolysis is notable for its ability to process all components of the biomass. This whole-biomass conversion minimizes waste and maximizes the yield of valuable fuel products from the input feedstock.

Potential for Self-Sustaining Operation

The process generates a non-condensable syngas (containing methane, hydrogen, and carbon monoxide) alongside the bio-oil. This gas can be captured and burned to provide the heat required to run the pyrolysis reactor, making the process partially or fully self-sustaining.

The Versatility of Co-Products

Fast pyrolysis doesn't just create one product; it creates a portfolio of useful materials, allowing for a more diversified and valuable output stream.

Bio-oil: A Renewable Fuel and Feedstock

The main product, bio-oil, can be used as a fuel for industrial boilers, engines, and turbines. It can also be upgraded into transportation fuels or serve as a source of renewable chemical commodities.

Bio-char: A Valuable Soil Amendment

The solid co-product, bio-char, is a stable form of carbon. It can be used to improve soil health and fertility, act as a sorbent for pollutants, or serve as a feedstock for producing activated carbon.

Understanding the Trade-offs

No technology is without its challenges. To make an informed decision, you must understand the associated costs and complexities.

High Initial Capital Cost

While the reactors can be simple, the overall cost of establishing a fast pyrolysis facility can be high. The specialized equipment required represents a significant upfront investment.

The Need for Product Upgrading

The raw bio-oil produced is not a direct substitute for petroleum products. It is acidic, unstable, and has a high oxygen content. It typically requires further processing and upgrading before it can be used as a transportation fuel or high-grade chemical feedstock, which adds complexity and cost.

Making the Right Choice for Your Goal

Your reason for considering fast pyrolysis will determine which advantage is most critical.

- If your primary focus is decentralized energy production: The ability to use small, mobile units to process biomass at the source and transport the resulting liquid fuel is its most powerful feature.

- If your primary focus is maximizing biomass value: The production of three distinct and marketable products—bio-oil, bio-char, and syngas—offers multiple revenue streams from a single feedstock.

- If your primary focus is speed and efficiency: Fast pyrolysis provides a rapid conversion route that utilizes the entire biomass input, minimizing waste and maximizing fuel output.

Ultimately, fast pyrolysis provides a powerful and flexible pathway to unlock the value stored in solid biomass.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Logistical Flexibility | Converts bulky biomass into transportable bio-oil, enabling decentralized production. |

| Process Efficiency | Rapid, high-yield conversion using the entire biomass feedstock. |

| Versatile Co-Products | Generates valuable bio-oil, bio-char, and syngas for multiple revenue streams. |

| Self-Sustaining Potential | Syngas byproduct can be used to power the process, reducing operational costs. |

Ready to harness the power of fast pyrolysis for your biomass conversion needs?

KINTEK specializes in providing robust laboratory equipment and consumables to support your research and development in renewable energy technologies. Whether you're exploring bio-oil production, bio-char applications, or process optimization, our solutions are designed to enhance your efficiency and accuracy.

Contact our experts today via our Contact Form to discuss how KINTEK can support your lab's innovative work in biomass pyrolysis and help you achieve your sustainability goals.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What is the physical vapor transport process? A Guide to High-Performance PVD Coatings

- Which gases are used in CVD process? A Guide to Precursors and Carrier Gases

- What are the methods for synthesis of carbon nanotubes review? From Arc Discharge to Scalable CVD

- What are the examples of CVD method? Discover the Versatile Applications of Chemical Vapor Deposition

- What is the CVD method of synthesis? A Guide to High-Purity Thin Film Deposition

- What is the role of a CVD system in SiC coating fabrication? Achieve Precise Nanocrystalline Results

- What are the advantages of thin film resistors? Precision, Stability & Low Noise for Sensitive Circuits

- Which is better, lab-grown diamond, CVD or HPHT? Focus on the 4Cs, Not the Method.