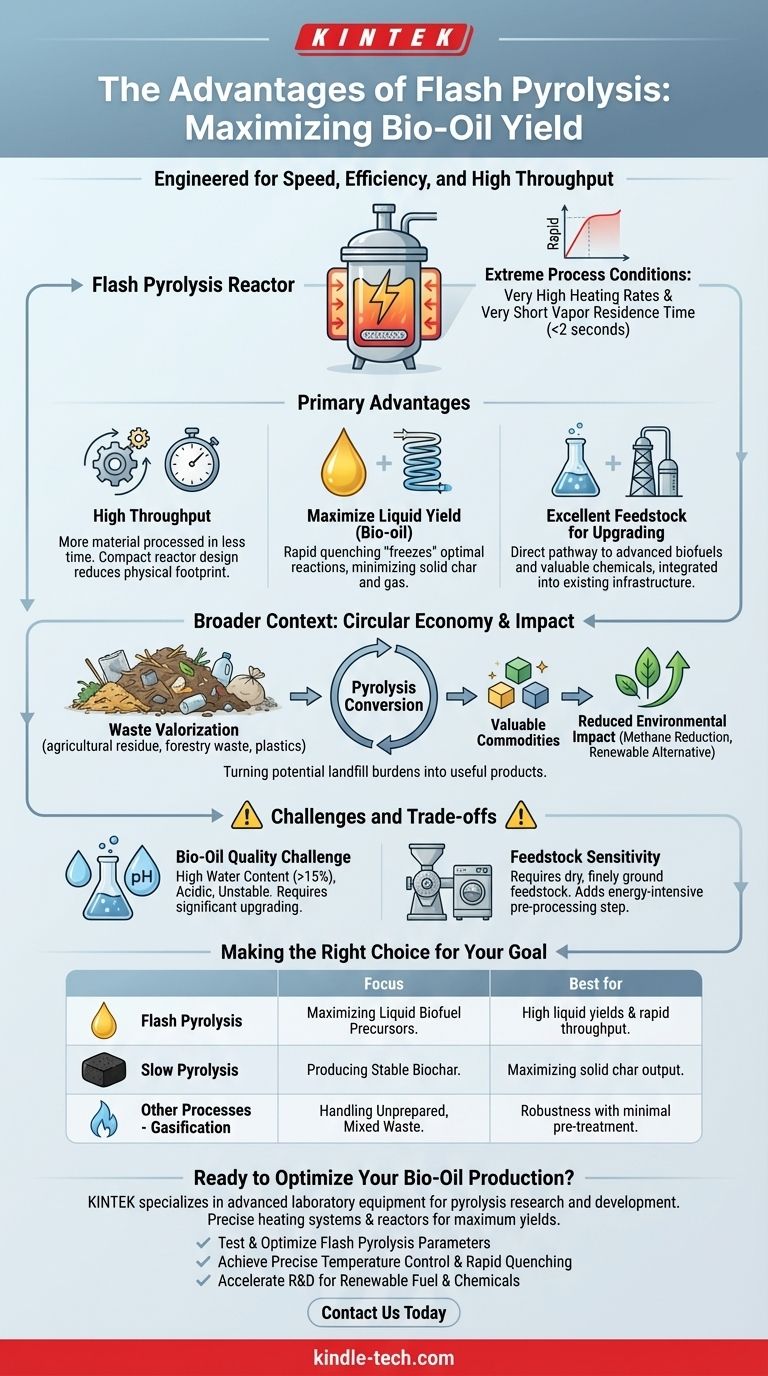

At its core, flash pyrolysis is a specialized thermal process engineered for speed and efficiency. Its primary advantages are significantly higher yields of liquid bio-oil, much faster processing times, and the ability to handle larger volumes of feedstock compared to slower pyrolysis methods, all within a similarly sized reactor.

The key advantage of flash pyrolysis is not just waste treatment, but targeted liquid fuel production. It rapidly heats organic material in the absence of oxygen to maximize the creation of bio-oil, intentionally minimizing the production of solid char and gas.

The Core Principle: Maximizing Liquid Yields

Flash pyrolysis is defined by its extreme process conditions: very high heating rates and a very short vapor residence time (typically less than two seconds). This precision is the source of its primary benefits.

The Advantage of Speed

The "flash" in the name refers to the rapid heating. This speed allows for a high throughput, meaning more material can be processed in less time.

This efficiency means that for a given processing capacity, a flash pyrolysis reactor can often be smaller and more compact than its slower counterparts, reducing the physical footprint of the operation.

The Advantage of Yield

The main goal of flash pyrolysis is to maximize the liquid product, known as bio-oil or pyrolysis oil.

By heating the material quickly and then rapidly cooling (quenching) the resulting vapors, the process effectively "freezes" the chemical reactions at their optimal point. This prevents the valuable liquid compounds from further breaking down into less desirable permanent gases and solid char.

A Better Feedstock for Upgrading

The resulting bio-oil, while needing further treatment, can serve as an excellent precursor for producing advanced biofuels and valuable chemicals. It provides a direct pathway from solid waste or biomass to a liquid intermediate that can be integrated into existing refinery infrastructure after upgrading.

The Broader Context: Why Pyrolysis Matters

Understanding the specific advantages of flash pyrolysis requires seeing its role in the wider field of waste valorization and renewable energy.

A Path to a Circular Economy

Pyrolysis technologies in general offer a powerful method for converting low-value or negative-value waste streams—such as agricultural residue, forestry waste, and certain plastics—into valuable commodities.

This process is a cornerstone of the circular economy, turning potential landfill burdens into useful products.

Reducing Environmental Impact

By diverting organic waste from landfills, pyrolysis reduces methane emissions, a potent greenhouse gas. It also creates a renewable alternative to fossil fuels.

Furthermore, it enables the recovery of materials from waste like tires and plastics, reducing the environmental and economic cost of extracting virgin raw materials.

Understanding the Trade-offs and Challenges

No technology is without its compromises. The precision and speed of flash pyrolysis come with specific operational challenges that must be managed.

The Challenge of Bio-Oil Quality

A significant disadvantage is that the raw bio-oil produced has a high water content, often over 15%.

This water, along with oxygenated organic compounds, makes the oil acidic, thermally unstable, and corrosive. It has a lower energy density than conventional fuels and requires a significant, often costly, upgrading step before it can be used as a drop-in fuel.

Feedstock Sensitivity

Flash pyrolysis works best with feedstock that is dry and finely ground to a consistent particle size. This ensures rapid and uniform heat transfer.

This requirement adds a necessary and energy-intensive pre-processing step (drying and grinding) to the overall operation, which can increase costs and complexity.

Making the Right Choice for Your Goal

Selecting the right thermal technology depends entirely on your primary objective.

- If your primary focus is maximizing liquid biofuel precursors: Flash pyrolysis is the ideal choice due to its high liquid yields and rapid throughput.

- If your primary focus is producing stable biochar for soil amendment: Slow pyrolysis is the superior method, as it is designed to maximize the solid char output.

- If your primary focus is handling unprepared, mixed waste with minimal pre-treatment: Other thermal processes like gasification or conventional combustion may be more robust and forgiving.

Ultimately, choosing flash pyrolysis is a strategic decision to prioritize the rapid conversion of biomass into a liquid chemical intermediate.

Summary Table:

| Feature | Flash Pyrolysis Advantage |

|---|---|

| Primary Product | Maximizes liquid bio-oil yield |

| Processing Speed | Very high heating rates & short vapor residence time (<2 seconds) |

| Throughput | High volume processing in a compact reactor |

| Best For | Targeted liquid fuel production from dry, fine feedstock |

| Key Challenge | Bio-oil requires upgrading due to high water content & acidity |

Ready to Optimize Your Bio-Oil Production?

KINTEK specializes in advanced laboratory equipment for pyrolysis research and development. Whether you are scaling up your process or optimizing feedstock conversion, our precise heating systems and reactors are designed to help you achieve maximum liquid yields and efficiency.

We help our laboratory customers:

- Test and optimize flash pyrolysis parameters for various feedstocks.

- Achieve precise temperature control and rapid quenching for superior bio-oil quality.

- Accelerate R&D for renewable fuel and chemical production.

Contact us today to discuss how our lab solutions can advance your pyrolysis projects. ➡️ Get in Touch

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds