The primary advantages of an induction melting furnace are its ability to produce high-quality, homogeneous metal with minimal loss, combined with significant operational efficiencies. This is achieved through fast, clean, and controllable heating, resulting in lower energy costs, a safer work environment, and reduced environmental impact compared to traditional combustion-based methods.

The core advantage of induction melting lies in its fundamental mechanism: heat is generated directly within the metal itself. This precision eliminates many of the inefficiencies, impurities, and hazards associated with external fuel sources, giving operators unparalleled control over the entire melting process.

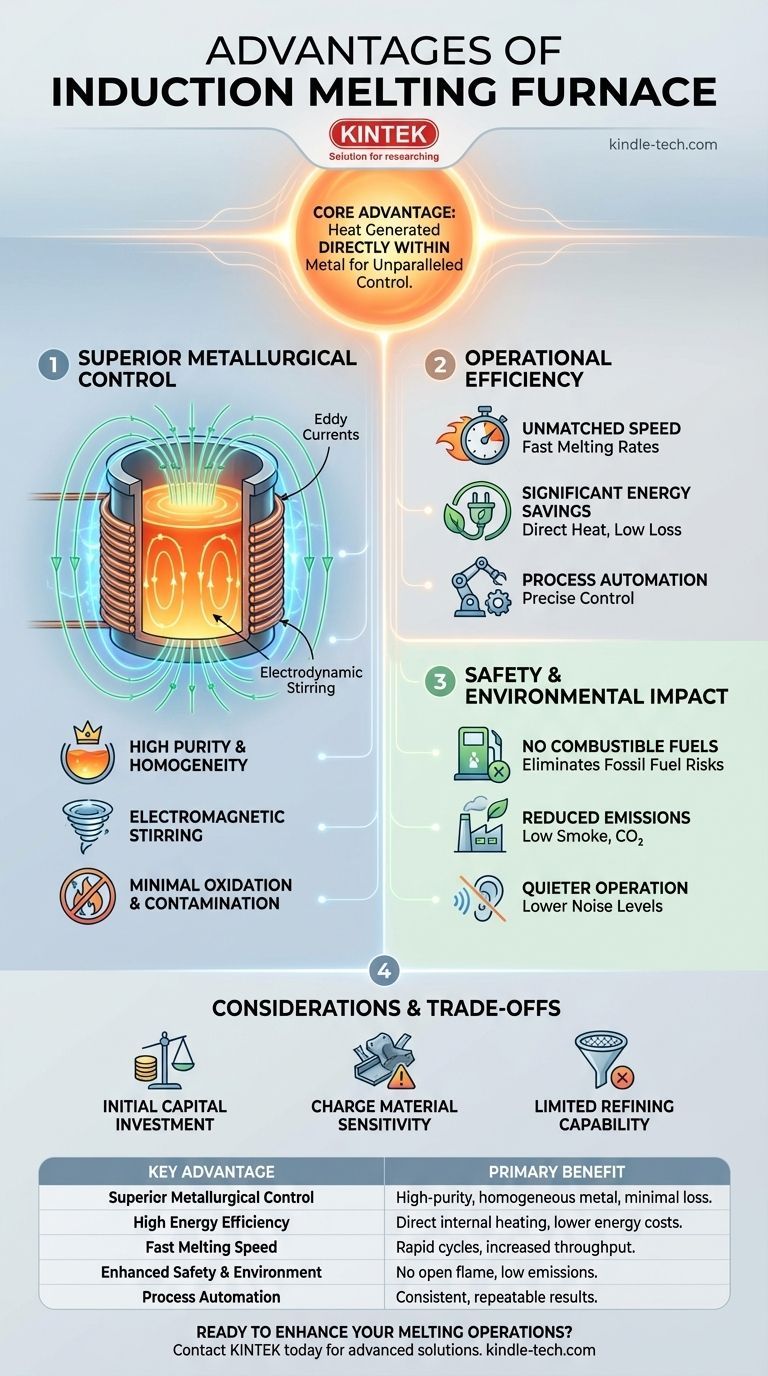

The Foundation: Superior Metallurgical Control

Induction technology's core strength is its ability to directly influence the metal, leading to a higher quality final product. This is not just an incremental improvement; it is a fundamental shift from how traditional furnaces operate.

How Induction Generates Heat

An induction furnace uses a powerful alternating current passed through a copper coil. This creates a strong, rapidly reversing magnetic field that penetrates the metal charge placed inside. This magnetic field induces powerful electrical currents—known as eddy currents—within the metal itself, which generate precise and rapid heat due to the metal's natural resistance.

The Benefit of Electromagnetic Stirring

A key secondary effect of this process is a natural stirring action within the molten metal bath. The magnetic fields create a "motor effect" that promotes electrodynamic circulation. This constant, gentle stirring ensures the melt achieves a highly uniform temperature and chemical composition, which is critical for producing consistent alloys and helps separate impurities (scum or slag) to the surface for easier removal.

Minimizing Oxidation and Contamination

Unlike fuel-fired furnaces, induction melting involves no combustion. There is no open flame, no exhaust gases, and no byproducts of burning fuel that can contaminate the metal. This significantly reduces metal loss from oxidation (burning) and prevents the introduction of impurities, leading to a cleaner, higher-yield melt.

Translating Control into Operational Efficiency

The precise nature of induction heating translates directly into measurable gains in speed, cost, and automation.

Unmatched Melting Speed

Because heat is generated instantly within the charge material, induction furnaces have extremely fast melting rates. They do not require a long preheating cycle and can be started and stopped quickly, offering immense operational flexibility and enabling 24-hour continuous smelting if needed.

Significant Energy Savings

Induction is a highly efficient process. The majority of the electrical energy is converted directly into heat within the metal, with very little heat loss to the surrounding environment. This makes it far more energy-efficient and cost-effective than processes that must first heat a chamber and then transfer that heat indirectly to the metal.

The Path to Automation

The process is controlled electrically, making it simple to operate and easy to integrate with automated systems. Temperature, power input, and thermal cycling can be precisely programmed and monitored, reducing the need for constant manual oversight and improving process repeatability.

Understanding the Trade-offs and Considerations

While powerful, induction technology is not a universal solution. An objective evaluation requires acknowledging its specific requirements and limitations.

Initial Capital Investment

Induction furnace systems often have a higher initial purchase price compared to simpler cupola or crucible furnaces. The decision must be based on a total cost of ownership analysis, which factors in long-term energy savings, higher yields, and reduced labor.

Sensitivity to Charge Material

The efficiency of induction heating can be affected by the quality of the scrap metal used. Very dirty, oily, or wet charge materials can introduce impurities and pose safety risks. Proper charge preparation is often necessary to achieve optimal results.

Limited Refining Capability

A standard induction furnace is primarily a melting device, not a refining vessel. While it excels at melting and alloying, it cannot remove certain undesirable elements (like phosphorus or sulfur) from the base metal. For applications requiring significant refining, other furnace types or secondary metallurgical processes are needed.

The Modern Foundry: Safety and Environmental Impact

Beyond performance, induction furnaces offer significant advantages in creating a safer and cleaner workplace.

Eliminating Combustible Fuels

The primary safety benefit is the elimination of highly combustible fossil fuels on the foundry floor. This removes the risks associated with storing, handling, and burning gas or oil, and eliminates the danger of an open flame.

Reducing Emissions and Noise

With no combustion, induction furnaces produce virtually no smoke, dust, or harmful gases like CO₂. This dramatically improves air quality both inside the facility and in the surrounding community. They are also significantly quieter in operation than arc furnaces or jet melters.

Making the Right Choice for Your Goal

Selecting the correct melting technology depends entirely on your operational priorities.

- If your primary focus is ultimate metal purity and alloy consistency: Induction is superior due to its contaminant-free heating and natural stirring effect.

- If your primary focus is rapid production and energy efficiency: The fast melting cycles and low thermal losses of induction offer a clear advantage for high-throughput foundries.

- If your primary focus is operational safety and environmental compliance: Induction's flameless, low-emission process is the modern standard for a clean and safe facility.

- If your primary focus is minimizing initial capital expense: You must carefully weigh the lower upfront cost of a traditional furnace against the higher long-term operational costs and lower yields.

By understanding its core principles, you can leverage induction technology to achieve a new level of precision and efficiency in your melting operations.

Summary Table:

| Key Advantage | Primary Benefit |

|---|---|

| Superior Metallurgical Control | Produces high-purity, homogeneous metal with minimal oxidation loss. |

| High Energy Efficiency | Direct internal heating reduces energy costs and thermal loss. |

| Fast Melting Speed | Rapid start-up and melting cycles increase production throughput. |

| Enhanced Safety & Environment | No open flame or combustible fuels; low emissions and noise. |

| Process Automation | Easy to program and integrate for consistent, repeatable results. |

Ready to enhance your melting operations with precision and efficiency?

KINTEK specializes in advanced lab equipment, including induction melting furnaces designed for superior performance. Our solutions help laboratories and foundries achieve higher purity metals, reduce operational costs, and maintain a safer working environment.

Contact us today to discuss how our induction melting technology can meet your specific needs and drive your success.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications