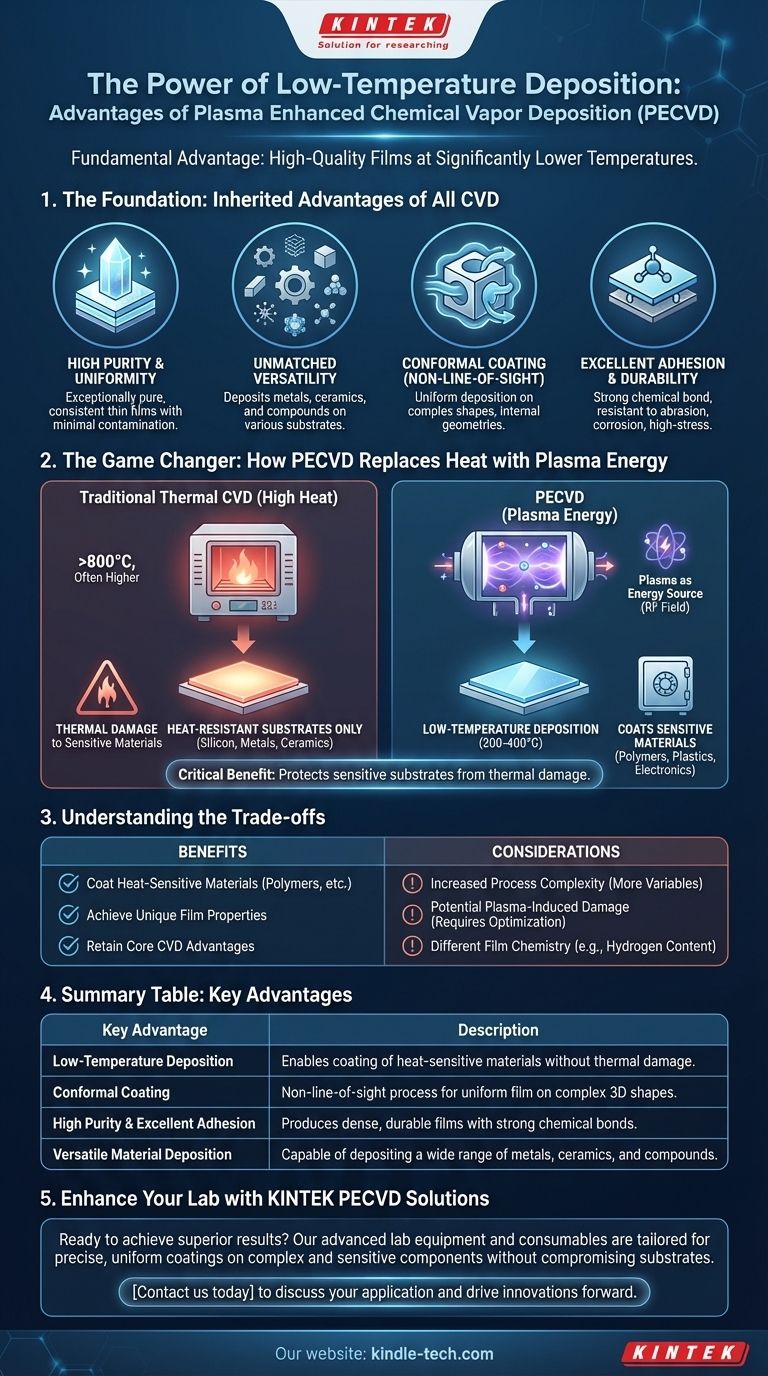

The fundamental advantage of Plasma Enhanced Chemical Vapor Deposition (PECVD) is its ability to deposit high-quality, uniform films at significantly lower temperatures than conventional Chemical Vapor Deposition (CVD). By using an energy-rich plasma to initiate chemical reactions instead of high heat, PECVD can coat materials that would otherwise melt, deform, or be destroyed by traditional thermal processes.

PECVD delivers the core benefits of conventional CVD—such as high purity and the ability to coat complex shapes—while overcoming its single greatest limitation: the need for extreme heat. This crucial difference makes it the ideal solution for depositing films on temperature-sensitive substrates.

The Foundation: Understanding General CVD Advantages

To appreciate what makes PECVD unique, we must first understand the powerful benefits inherent to all CVD processes. PECVD inherits this entire feature set.

High Purity and Uniformity

CVD processes excel at creating exceptionally pure, dense, and uniform thin films. The gas-phase precursors can be refined to very high purity levels, resulting in coatings with minimal contamination and consistent thickness across the entire substrate.

Unmatched Versatility

Because the process is driven by chemical reactions, CVD is incredibly versatile. It can be used to deposit a vast range of materials, including metals, ceramics, and specialized compounds, onto an equally wide range of substrates.

Conformal Coating on Complex Shapes

CVD is a non-line-of-sight process. The precursor gases flow and diffuse around the target object, allowing the deposition to occur evenly on all surfaces, including intricate, complex, and internal geometries that are impossible to coat with line-of-sight methods like sputtering.

Excellent Adhesion and Durability

The deposited films form a strong chemical bond with the substrate, resulting in durable coatings with excellent adhesion. These layers can be engineered to be highly resistant to abrasion, corrosion, and high-stress environments.

The Key Differentiator: How Plasma Changes the Game

While conventional CVD is powerful, its reliance on heat creates a significant barrier. PECVD directly solves this problem.

The Problem with High Heat

Traditional thermal CVD requires extremely high temperatures, often many hundreds or even thousands of degrees Celsius, to provide enough energy to break down the precursor gases and drive the desired chemical reactions. This limits its use to robust, heat-resistant substrates like silicon wafers, metals, and ceramics.

Plasma as the Energy Source

PECVD replaces thermal energy with electrical energy. An electromagnetic field (typically Radio Frequency, or RF) is applied to the precursor gases, stripping electrons from their atoms and creating a plasma—an ionized, highly reactive gas.

The Critical Benefit: Low-Temperature Deposition

This plasma is packed with high-energy electrons that collide with the precursor gas molecules. These collisions provide the energy needed to break chemical bonds and initiate the deposition reaction, all while the substrate itself remains at a much lower temperature (e.g., 200-400°C instead of >800°C). This protects sensitive substrates like polymers, plastics, and complex electronic components from thermal damage.

Understanding the Trade-offs

While powerful, PECVD introduces its own set of considerations that differ from simpler thermal methods.

Increased Process Complexity

The addition of a plasma system introduces more variables that must be precisely controlled. Factors like RF power, pressure, gas flow rates, and chamber geometry all influence the film's final properties, requiring more sophisticated equipment and process control.

Potential for Plasma-Induced Damage

While PECVD avoids thermal damage, the high-energy ions within the plasma can sometimes physically bombard and damage the substrate surface or the growing film if the process is not carefully optimized.

Different Film Chemistry

Films deposited via PECVD can have different chemical compositions and internal stress profiles compared to those grown with high-temperature thermal CVD. For example, silicon nitride films from PECVD often contain significant amounts of hydrogen, which can affect their optical and electrical properties.

Making the Right Choice for Your Application

Selecting the right deposition method depends entirely on your substrate and desired outcome.

- If your primary focus is coating heat-resistant substrates like metals or ceramics: Traditional thermal CVD may offer a simpler and more established process without the complexities of plasma generation.

- If your primary focus is depositing films on temperature-sensitive materials: PECVD is the definitive choice, as it is specifically designed to prevent thermal damage to substrates like polymers, plastics, or fully assembled integrated circuits.

- If your primary focus is achieving unique film properties: The distinct, plasma-driven reaction chemistry of PECVD can produce films with compositions and characteristics that are difficult or impossible to achieve with purely thermal methods.

Ultimately, PECVD expands the power of chemical vapor deposition to a new class of materials, enabling advanced applications previously limited by thermal constraints.

Summary Table:

| Key Advantage | Description |

|---|---|

| Low-Temperature Deposition | Enables coating of heat-sensitive materials (e.g., polymers, plastics) without thermal damage. |

| Conformal Coating | Non-line-of-sight process ensures uniform film deposition on complex 3D shapes. |

| High Purity & Excellent Adhesion | Produces dense, durable films with strong chemical bonds to the substrate. |

| Versatile Material Deposition | Capable of depositing a wide range of metals, ceramics, and specialized compounds. |

Ready to enhance your lab's capabilities with Plasma Enhanced Chemical Vapor Deposition?

KINTEK specializes in providing advanced lab equipment and consumables tailored to your research and production needs. Whether you're working with temperature-sensitive polymers or require precise, uniform coatings on complex components, our PECVD solutions can help you achieve superior results without compromising your substrates.

Contact us today to discuss how our expertise can support your specific application and drive your innovations forward.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application