At its core, the primary advantages of Physical Vapor Deposition (PVD) over Chemical Vapor Deposition (CVD) are its significantly lower operating temperature and its ability to precisely replicate the substrate's original surface finish. This makes PVD ideal for coating heat-sensitive materials and components where maintaining a specific finish without post-processing is critical.

The choice between PVD and CVD hinges on a fundamental trade-off: PVD offers lower temperatures and superior finish control for line-of-sight applications, while CVD excels at uniformly coating complex, non-line-of-sight geometries despite its high heat requirements.

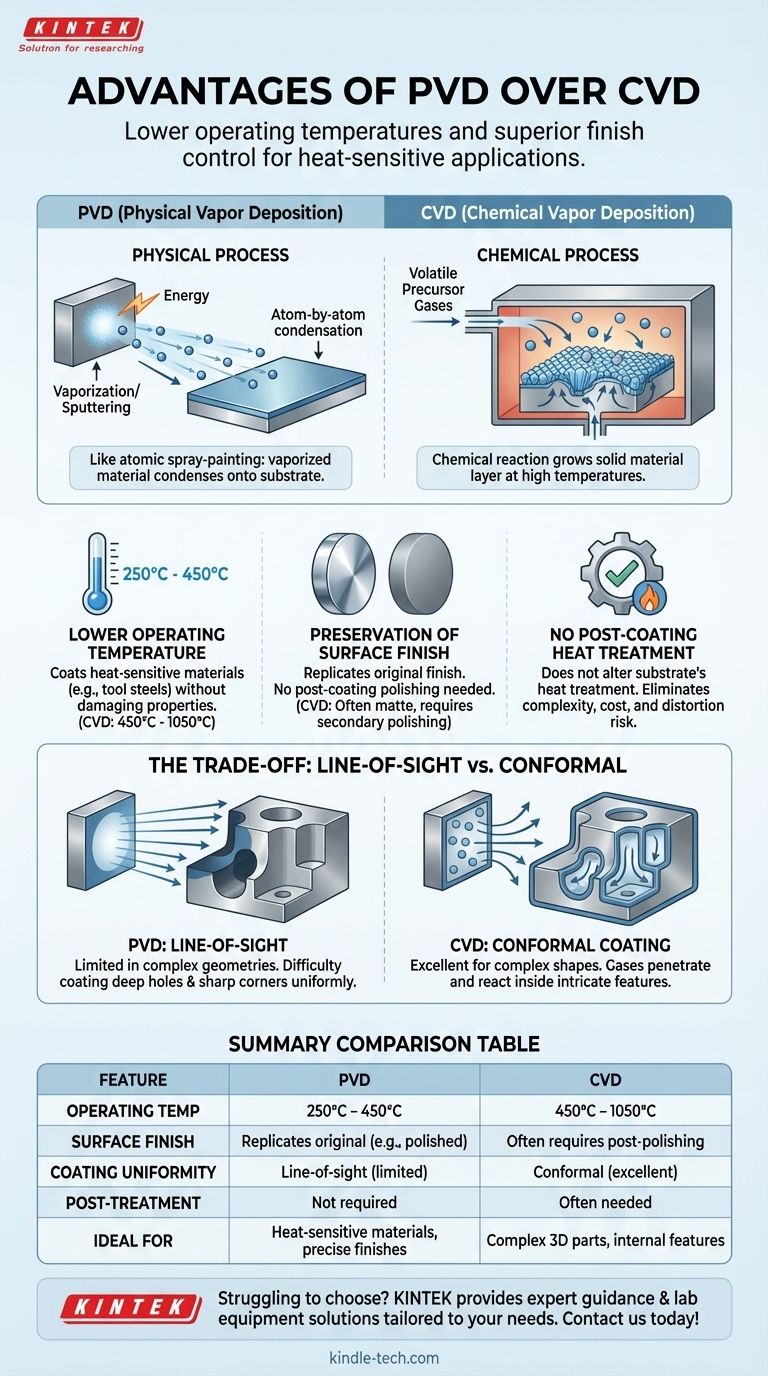

The Fundamental Process Distinction

To understand the advantages, it's crucial to recognize how these processes differ. They are not merely variations of the same technique; they are fundamentally different approaches to depositing a thin film.

PVD: A Physical Process

PVD is a physical process. It takes a solid or liquid source material, vaporizes it using physical means (like heating or sputtering), and then condenses that vapor atom-by-atom onto the substrate's surface.

Think of it like spray-painting, but on an atomic level, where the "paint" is a vaporized metal or ceramic.

CVD: A Chemical Process

CVD is a chemical process. It introduces volatile precursor gases into a reaction chamber. These gases decompose and react with each other and the substrate, which is heated to very high temperatures, forming a new solid material layer on its surface.

This is more akin to growing a crystalline layer on the substrate, with the final coating being the result of a chemical reaction.

Key Advantages of PVD Explained

The physical nature of PVD and its lower temperature create distinct operational advantages over the high-temperature chemical reactions of CVD.

Lower Operating Temperature

PVD processes typically run at much lower temperatures, often between 250°C and 450°C.

This is a significant advantage because it allows for the coating of materials that cannot withstand the intense heat of CVD, which often operates between 450°C and 1050°C.

This makes PVD suitable for a wider range of substrates, including many hardened tool steels, alloys, and other materials whose fundamental properties (like temper) would be ruined by the heat of CVD.

Preservation of Surface Finish

PVD coatings replicate the original surface finish of the part. If you coat a highly polished component with PVD, the result will be a highly polished coating.

CVD, by contrast, often results in a dull or matte finish due to its chemical growth process. Achieving a polished finish on a CVD-coated part typically requires an expensive and time-consuming secondary polishing step.

No Post-Coating Heat Treatment

Because PVD is a low-temperature process, it does not alter the heat treatment of the underlying substrate.

Parts coated with high-temperature CVD often must be heat-treated again after coating to restore their desired hardness and mechanical properties, adding complexity, cost, and the risk of part distortion.

Understanding the Trade-offs: The Case for CVD

To make an objective decision, it is essential to understand where PVD falls short and CVD excels. The primary limitation of PVD is its reliance on a direct path from the source to the substrate.

The Line-of-Sight Limitation of PVD

PVD is a line-of-sight process. The coating material travels in a straight line from the source to the part being coated.

This means it is very difficult to coat deep holes, sharp interior corners, or other complex, "shadowed" geometric features uniformly.

The Conformal Coating Advantage of CVD

CVD is not limited by line-of-sight. The precursor gases flow and diffuse throughout the chamber, allowing them to penetrate and react inside intricate shapes and internal cavities.

This results in a highly conformal coating that is uniform across even the most complex surfaces, which is something PVD cannot achieve.

Making the Right Choice for Your Goal

Your choice depends entirely on the specific requirements of your material, geometry, and desired outcome.

- If your primary focus is coating a heat-sensitive material: PVD is the clear choice, as it avoids the high temperatures that would damage the substrate.

- If your primary focus is preserving a specific surface finish (e.g., polished or textured): PVD is superior because it directly replicates the original surface without needing secondary processing.

- If your primary focus is uniformly coating a complex part with deep holes or internal channels: CVD is the only viable option due to its non-line-of-sight, gas-based deposition process.

Ultimately, selecting the correct coating technology requires matching the process's inherent strengths to the non-negotiable demands of your application.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Operating Temperature | 250°C - 450°C | 450°C - 1050°C |

| Surface Finish | Replicates original finish (e.g., polished) | Often requires post-coating polishing |

| Coating Uniformity | Line-of-sight (limited in complex geometries) | Conformal (excellent for complex shapes) |

| Post-Coating Treatment | Not required | Often needed to restore substrate properties |

| Ideal For | Heat-sensitive materials, precise finishes | Complex 3D parts with internal features |

Struggling to choose between PVD and CVD for your lab's coating needs? KINTEK specializes in lab equipment and consumables, providing expert guidance and solutions tailored to your specific application. Whether you need the low-temperature precision of PVD for sensitive materials or the uniform coverage of CVD for complex parts, our team is here to help you achieve optimal results. Contact us today to discuss your project and discover the right coating technology for your laboratory!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process