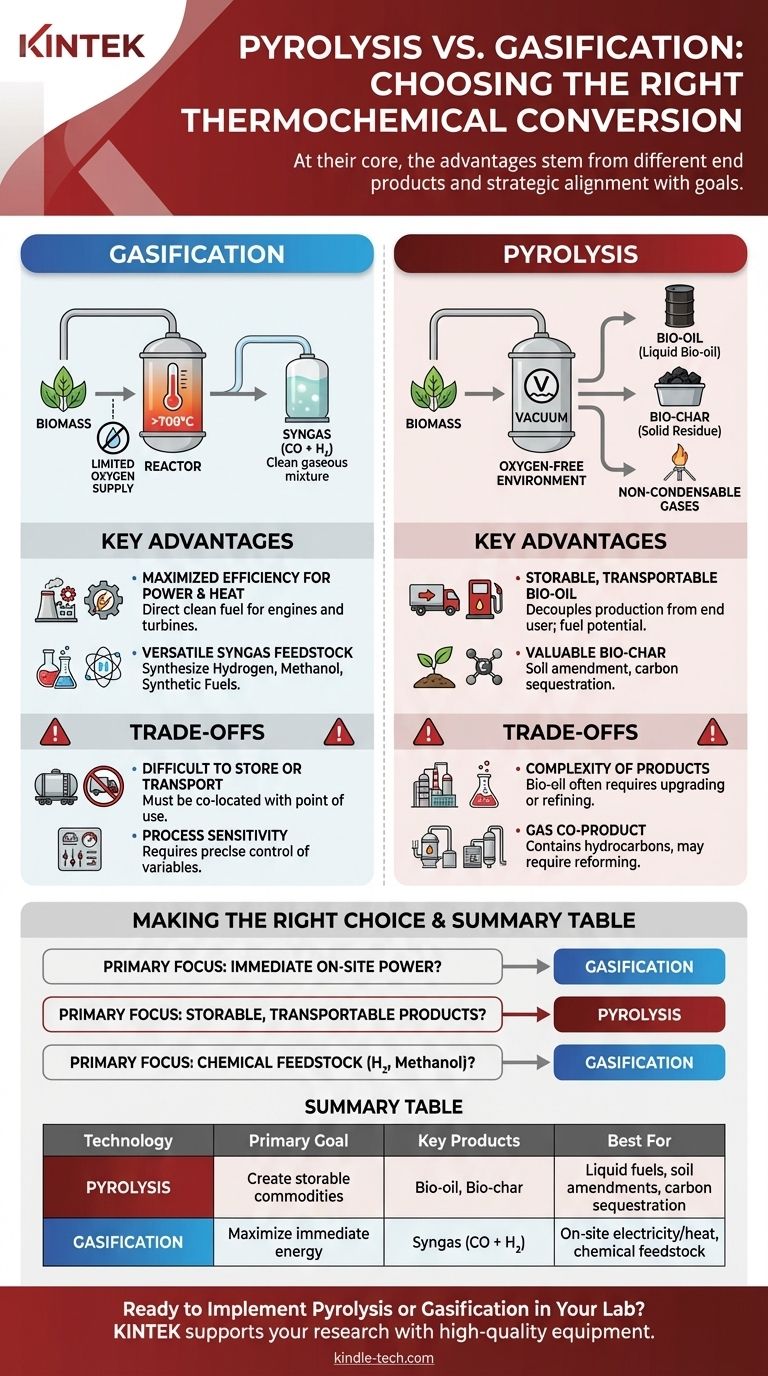

At their core, the advantages of pyrolysis and gasification stem from their different end products. Gasification is engineered to maximize the production of a combustible gas (syngas) for immediate energy generation, making it highly efficient for electricity and heat. In contrast, pyrolysis is designed to create valuable and storable products, specifically a liquid bio-oil and a solid bio-char, by breaking down materials in an oxygen-free environment.

The choice between these technologies is not about which is universally "better," but which is strategically aligned with your end goal. Gasification is the superior choice for direct, on-site energy production, while pyrolysis excels at creating valuable, transportable commodities.

Understanding the Core Processes

To grasp the distinct advantages, it's essential to understand how each process works. Both are thermochemical conversion technologies that heat organic materials to create fuel, but their operating conditions lead to fundamentally different outcomes.

Gasification: Partial Oxidation for Gaseous Fuel

Gasification exposes biomass to very high temperatures (typically above 700°C) in the presence of a controlled, limited amount of oxygen or steam.

This is not complete combustion. Instead, the process is designed to break down complex organic matter into its simplest, most energy-dense gaseous components: primarily carbon monoxide (CO) and hydrogen (H₂). This mixture is known as synthesis gas, or syngas.

Pyrolysis: Thermal Decomposition Without Oxygen

Pyrolysis involves heating organic materials in a completely oxygen-free environment. The absence of oxygen prevents combustion and instead causes the material to thermally decompose into three distinct products.

These products are a liquid known as bio-oil (or pyrolysis oil), a solid residue called bio-char, and a mixture of non-condensable gases.

Key Advantages of Gasification

Gasification's primary advantage is its efficiency in converting biomass directly into a clean, combustible fuel suitable for immediate use.

Maximized Efficiency for Power and Heat

Gasification is generally considered more efficient than pyrolysis for the direct production of electricity and heat.

The syngas it produces is a relatively clean and consistent fuel that can be fed directly into gas engines or turbines to generate power, making it a very direct waste-to-energy pathway.

Production of Versatile Syngas

Syngas is not just a fuel for combustion; it is a fundamental chemical building block.

The CO and H₂ in syngas can be used as a feedstock in chemical processes to synthesize valuable products like hydrogen, methanol, and other synthetic fuels. This opens up applications beyond simple power generation.

Key Advantages of Pyrolysis

Pyrolysis shines in its ability to create multiple, distinct products that can be stored, transported, and sold as valuable commodities.

Creation of Storable, Transportable Bio-oil

The single greatest advantage of pyrolysis is its production of a liquid bio-oil. Unlike syngas, which must be used on-site or stored under high pressure, bio-oil is a dense, storable, and transportable liquid.

This decouples the biomass processing plant from the end user. Bio-oil can be refined into transportation fuels or used to replace heating oil in industrial boilers.

Production of Valuable Bio-char

Pyrolysis creates a stable, carbon-rich solid known as bio-char. This is not a waste product but a co-product with significant value.

Bio-char is an excellent soil amendment, improving soil structure, water retention, and fertility. It also serves as a method for long-term carbon sequestration, locking carbon into the soil for centuries.

Understanding the Trade-offs

Choosing a technology requires acknowledging its limitations. The ideal output of one process is often a challenge for the other.

The Complexity of Pyrolysis Products

While bio-oil is storable, it is also a complex mixture that is typically acidic, viscous, and unstable. It often requires significant upgrading or refining before it can be used as a drop-in transportation fuel.

Furthermore, the gas co-product from pyrolysis contains hydrocarbons that may require an additional processing step, such as reforming, to produce a clean syngas.

The Immediacy of Gasification Products

The primary product of gasification, syngas, is a hot gas that is difficult and uneconomical to store or transport over long distances.

This means a gasification facility must be co-located with its point of use, such as a power plant or chemical factory, limiting its operational flexibility.

Process Sensitivity and Control

The output and efficiency of both processes are highly sensitive to variables like feedstock type, moisture content, temperature, and pressure. Achieving the desired product slate requires sophisticated engineering and precise process control, making neither a simple, "one-size-fits-all" solution.

Making the Right Choice for Your Goal

Your decision must be driven by your primary objective and business model. Evaluate your goals against the core strengths of each technology.

- If your primary focus is maximizing immediate electricity or heat generation on-site: Gasification is the more direct and efficient pathway for converting biomass into power.

- If your primary focus is producing storable, transportable products like liquid fuels or valuable soil amendments: Pyrolysis offers the unique advantage of creating bio-oil and bio-char.

- If your primary focus is creating a chemical feedstock like pure hydrogen or methanol: Gasification is often the preferred route as it directly yields the clean syngas required for these syntheses.

Ultimately, the best technology is the one whose products best align with your specific market and logistical capabilities.

Summary Table:

| Technology | Primary Goal | Key Products | Best For |

|---|---|---|---|

| Pyrolysis | Create storable, transportable commodities | Bio-oil, Bio-char | Producing liquid fuels, soil amendments, carbon sequestration |

| Gasification | Maximize immediate energy generation | Syngas (CO + H₂) | On-site electricity/heat production, chemical feedstock (e.g., hydrogen) |

Ready to Implement Pyrolysis or Gasification in Your Lab?

Choosing the right thermochemical conversion technology is critical for your project's success. KINTEK specializes in providing high-quality lab equipment and consumables to support your research and development in pyrolysis, gasification, and biomass conversion.

Our expertise can help you:

- Test and optimize processes with reliable, precision equipment.

- Scale your technology from lab bench to pilot plant.

- Achieve accurate results with instruments designed for controlled thermal decomposition.

Let's build your ideal waste-to-energy solution together. Contact our experts today to discuss your specific laboratory needs!

Visual Guide

Related Products

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Custom PTFE Teflon Parts Manufacturer PTFE Beaker and Lids

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- What are the advantages of pyrolysis system? Turn Waste into Renewable Energy & Revenue

- What can pyrolysis oil be used for? A Guide to Fuel, Chemicals, and Waste Valorization

- What are the emissions from pyrolysis? Transforming Waste into Valuable, Controllable Products

- What energy product is produced by pyrolysis? Biochar, Bio-oil, and Syngas Explained

- What is bio-oil from biomass? A Guide to Pyrolysis Oil Production and Uses

- What are the methods of producing bio-oil? The Definitive Guide to Pyrolysis and Alternative Biofuel Processes

- Why is gasification better than pyrolysis? Maximize Energy Output vs. Create Valuable Products

- Why are industrial rotary furnaces utilized for hematite phase transformation? Optimize Your Ore Processing Today