The fundamental advantage of fluidization is its ability to make a bed of solid particles behave like a fluid. By suspending solids in an upward-flowing gas or liquid, the process creates a system with exceptionally uniform temperatures and rapid heat and mass transfer rates. This unique characteristic makes it an invaluable tool for a wide range of industrial applications, from chemical reactions to drying processes.

Fluidization offers unparalleled process control, especially regarding temperature, which dramatically improves reaction efficiency and product consistency. However, these benefits come with significant engineering challenges, including particle attrition, erosion, and complex hydrodynamics that must be carefully managed.

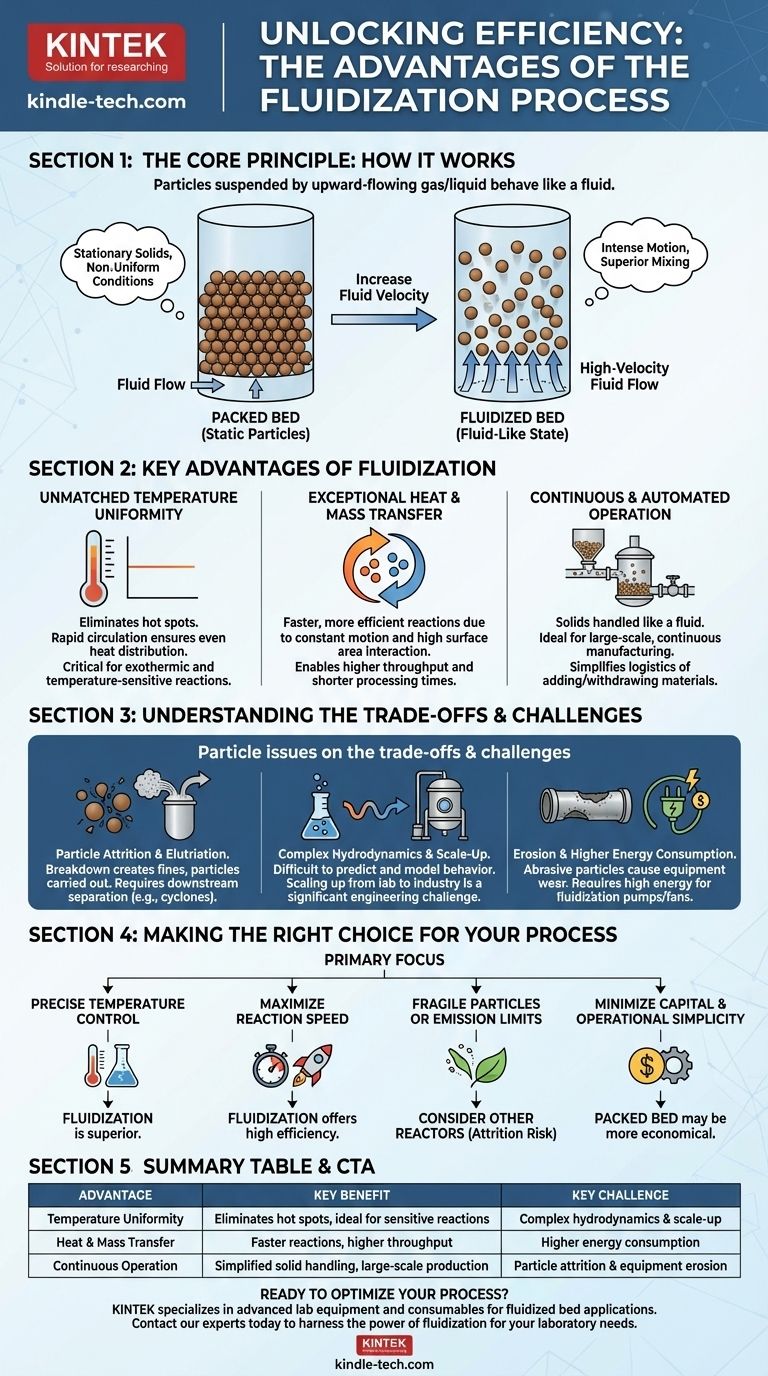

The Core Principle: How Fluidization Works

Creating a Fluid-Like State

Fluidization occurs when a fluid (gas or liquid) is passed up through a bed of granular solid particles at a velocity high enough to suspend them. As the fluid velocity increases, the drag force on the particles counteracts the force of gravity, causing the bed to expand and behave like a boiling liquid.

This "fluidized" state is characterized by intense particle motion and mixing, which is the source of its primary advantages. It stands in stark contrast to a packed bed, where particles are stationary and fluid flows through the gaps, often leading to non-uniform conditions.

Superior Mixing and Contact

The vigorous mixing ensures that every particle is constantly surrounded by the fluidizing medium. This creates an enormous surface area for interaction between the solid and the fluid, a condition that is difficult to achieve in other reactor types.

Key Advantages of the Fluidization Process

Unmatched Temperature Uniformity

The rapid circulation of solid particles ensures that heat is distributed evenly throughout the entire bed. This virtually eliminates hot spots, which are localized areas of high temperature that can occur in packed beds.

This precise temperature control is critical for highly exothermic reactions (those that release heat), preventing thermal runaway and catalyst deactivation. It also ensures consistent product quality in temperature-sensitive processes.

Exceptional Heat and Mass Transfer

The constant motion of particles and the intimate contact with the fluid lead to extremely high rates of heat and mass transfer. This allows reactions to proceed much faster and more efficiently than in a static system.

For processes like drying granular materials or coating particles, this means significantly shorter processing times and higher throughput.

Continuous and Automated Operation

Because the solids behave like a fluid, they can be continuously added to and withdrawn from the reactor system using standard pipes and valves. This makes fluidized beds ideal for large-scale, continuous manufacturing operations.

This simplifies solid handling, which can be a major logistical challenge in processes that require the frequent replacement or transport of solid catalysts or reactants.

Understanding the Trade-offs and Challenges

Particle Attrition and Elutriation

The constant collisions between particles and with the reactor walls can cause the particles to break down, a process known as attrition. This creates fine dust that can be problematic.

Furthermore, smaller or lighter particles can be carried out of the reactor by the upward-flowing fluid, a phenomenon called elutriation. This requires expensive downstream separation equipment, like cyclones or filters, to capture the lost material and prevent emissions.

Complex Hydrodynamics and Scale-Up

The behavior of a fluidized bed (e.g., bubbling, slugging) is complex and can be difficult to predict and model accurately. This makes scaling up a design from a small laboratory pilot plant to a large industrial unit a significant engineering challenge.

Improper scale-up can lead to poor performance, operational instability, or even failure, representing a considerable financial risk.

Erosion of Equipment

The abrasive action of the moving solid particles can cause significant wear and tear on the internal components of the reactor, including the vessel walls, heat exchanger tubes, and fluid distributor plate. This erosion reduces the lifespan of the equipment and increases maintenance costs.

Higher Energy Consumption

Maintaining the fluidization of a particle bed requires continuous power to operate the large fans or pumps that supply the fluidizing gas or liquid. The energy required to overcome the pressure drop across the bed is often higher than that for a comparable packed bed reactor, leading to higher operational costs.

Making the Right Choice for Your Process

Choosing fluidization requires balancing its powerful advantages against its inherent engineering complexities. Your decision should be guided by the most critical requirements of your specific application.

- If your primary focus is precise temperature control for sensitive reactions: Fluidization is often the superior choice to eliminate hot spots and ensure product consistency.

- If your primary focus is maximizing reaction speed and throughput: The exceptional heat and mass transfer rates in a fluidized bed can deliver unmatched process efficiency.

- If you are handling very fragile particles or have strict emissions limits: The risks of attrition and elutriation may require costly mitigation systems, potentially making other reactor types more attractive.

- If your primary focus is minimizing initial capital cost and operational simplicity: A packed bed may be a more straightforward and economical solution, provided your process can tolerate some temperature non-uniformity.

Ultimately, fluidization is a powerful tool for processes where its exceptional control over temperature and mixing justifies the investment in its more demanding design and operation.

Summary Table:

| Advantage | Key Benefit | Key Challenge |

|---|---|---|

| Temperature Uniformity | Eliminates hot spots, ideal for sensitive reactions | Complex hydrodynamics & scale-up |

| Heat & Mass Transfer | Faster reactions, higher throughput | Higher energy consumption |

| Continuous Operation | Simplified solid handling, large-scale production | Particle attrition & equipment erosion |

Ready to optimize your process with fluidization technology? KINTEK specializes in providing advanced lab equipment and consumables to help you harness the power of fluidized beds for superior temperature control, efficient reactions, and scalable production. Whether you're developing a new process or scaling up an existing one, our expertise can help you navigate the challenges and maximize the benefits. Contact our experts today to discuss your specific laboratory needs!

Visual Guide

Related Products

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Wall Mounted Water Distillation Unit

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What is the advantage of using high-pressure hydrothermal reactors to treat biomass waste? Efficient Resource Recovery

- Why use high-pressure reactors for food waste pretreatment? Boost Hydrogen Production Efficiency Today!

- Why is a high-pressure hydrothermal synthesis autoclave necessary for MnO2 nanowires? Precision Catalyst Growth

- Why are high-precision pressure sensors and temperature control systems critical for hydrothermal reaction equilibrium?

- What is the function of a PTFE-lined hydrothermal autoclave in cys-CDs synthesis? Achieve High-Purity Carbon Dots