In particle size analysis, the primary advantages of the sieve method are its simplicity, low cost, and ability to deliver rapid, reproducible results. This technique uses a stack of woven-wire mesh sieves with precise openings to physically separate particles by size, making it a foundational method in quality control and material characterization for a broad range of industries.

The enduring value of sieve analysis isn't just its low cost; it's the method's direct, physical measurement. Unlike more complex techniques that infer size from other properties, sieving provides a tangible, verifiable separation of material fractions.

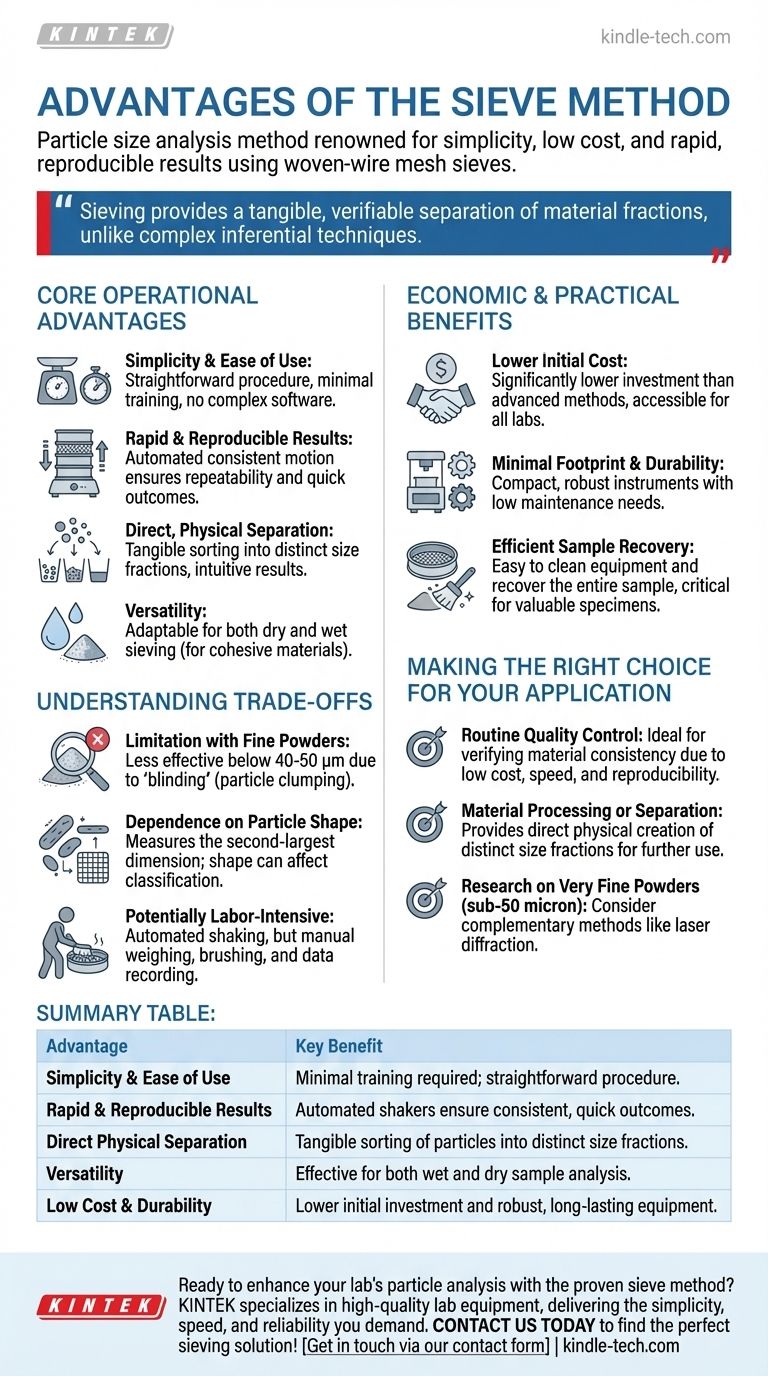

The Core Operational Advantages

The sieve method, particularly when automated with a sieve shaker, provides several key benefits that have made it a laboratory staple for decades.

Simplicity and Ease of Use

The procedure is exceptionally straightforward: weigh a sample, place it on a stack of sieves, run the shaker for a set time, and then weigh the material retained on each sieve. This process requires minimal operator training and no complex software.

Rapid and Reproducible Results

Modern sieve shakers utilize a consistent motion (such as a 3-D throwing motion) to ensure particles have the maximum opportunity to pass through the apertures. This automation delivers highly repeatable results quickly, removing variability between different operators or tests.

Direct, Physical Separation

Sieving physically sorts the sample into different size fractions. You are not inferring size from an abstract property like light diffraction; you are holding the separated particles. This makes the results intuitive and easy to verify.

Versatility for Wet and Dry Samples

The method is highly adaptable. While dry sieving is most common, wet sieving can be used for materials that are cohesive or tend to agglomerate, ensuring even fine particles are separated effectively.

Economic and Practical Benefits

Beyond its operational performance, sieving is often the most practical choice due to its low cost of entry and minimal facility requirements.

Lower Initial Cost

Compared to advanced methods like laser diffraction or dynamic image analysis, the initial investment for a sieve shaker and a set of certified sieves is significantly lower. This makes it accessible for labs of all sizes.

Minimal Footprint and Durability

Sieve shakers are compact instruments that require minimal bench space. Constructed from robust materials like stainless steel, they are built for longevity and demand very little maintenance.

Efficient Sample Recovery

The design of modern sieves and shakers makes it easy to clean the equipment and recover the entire sample. This is especially critical when working with small or valuable specimens.

Understanding the Trade-offs

No method is perfect for every scenario. To use sieving effectively, it's crucial to understand its limitations.

Limitation with Fine Powders

Sieving becomes progressively less effective for very fine powders, typically below 40-50 micrometers (µm). At this scale, forces like static electricity and cohesion can cause particles to clump together and block the mesh apertures, a phenomenon known as blinding.

Dependence on Particle Shape

A sieve analysis measures a particle's second-largest dimension, as this dictates whether it can pass through a square opening. Elongated or flat particles may be classified in a smaller size fraction than their volume or mass would suggest, which can differ from results obtained by other methods.

Potentially Labor-Intensive

While the shaking process is automated, the pre- and post-test steps—weighing the sample, manually brushing and weighing each fraction, and recording data—can be more labor-intensive than fully automated systems.

Making the Right Choice for Your Application

Selecting the correct analysis method depends entirely on your specific goal.

- If your primary focus is routine quality control: The sieve method's low cost, speed, and high reproducibility make it an ideal choice for verifying material consistency against established specifications.

- If your primary focus is material processing or separation: Sieving provides a direct, physical way to create distinct size fractions for further use or analysis, something indirect methods cannot do.

- If your primary focus is research on very fine powders (sub-50 micron): You should consider complementary methods like laser diffraction, as sieving loses accuracy and becomes impractical in this range.

Ultimately, the sieve method remains a trusted standard because it offers an unparalleled balance of simplicity, reliability, and cost-effectiveness for a wide range of particle sizing tasks.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Simplicity & Ease of Use | Minimal training required; straightforward procedure. |

| Rapid & Reproducible Results | Automated shakers ensure consistent, quick outcomes. |

| Direct Physical Separation | Tangible sorting of particles into distinct size fractions. |

| Versatility | Effective for both wet and dry sample analysis. |

| Low Cost & Durability | Lower initial investment and robust, long-lasting equipment. |

Ready to enhance your lab's particle analysis with the proven sieve method?

KINTEK specializes in high-quality lab equipment, including robust sieve shakers and certified test sieves, designed to deliver the simplicity, speed, and reliability your quality control process demands. Our solutions help you achieve accurate material characterization and consistent results.

Contact us today to discuss your specific application and find the perfect sieving solution for your laboratory. Get in touch via our contact form!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process

- How is a vibratory sieve shaker used in the particle size analysis of mechanically alloyed powders? Expert Guide

- What is the function of sieving equipment in CuAlMn alloys? Master Pore Size Precision

- Why is sieve analysis important? Ensure Consistent Quality and Performance of Your Materials

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis