At their core, tube furnaces offer an unparalleled combination of precise temperature control, atmospheric purity, and operational efficiency. Their primary advantage lies in creating an exceptionally uniform heating environment within a contained tube, making them indispensable for advanced material synthesis, thermal processing, and high-temperature testing where consistency is non-negotiable.

The true value of a tube furnace is not just its ability to get hot, but its power to create a highly controlled and reproducible thermal environment. This makes it a critical tool for processes sensitive to both temperature variation and atmospheric contamination.

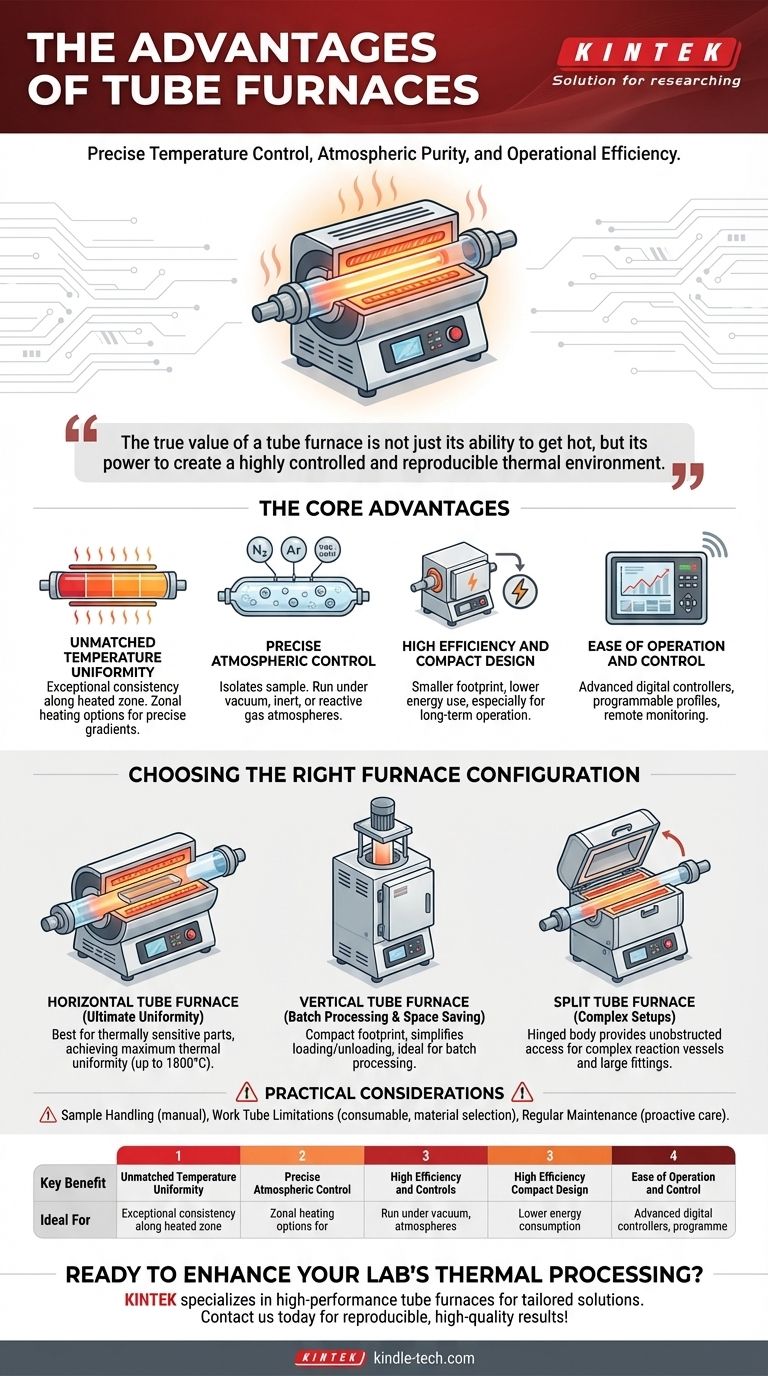

The Core Advantages of Tube Furnaces

A tube furnace's unique cylindrical design is the source of its primary benefits. By arranging heating elements around a central tube, it overcomes many limitations of standard box furnaces.

Unmatched Temperature Uniformity

The fundamental design of a tube furnace ensures exceptional temperature uniformity along the length of the heated zone. This consistency is critical for achieving reliable and repeatable results.

For more advanced applications, many models offer zonal heating. This divides the furnace into multiple programmable zones, allowing for precise temperature gradients or an even more uniform flat zone.

Precise Atmospheric Control

The sealed work tube isolates the sample from the outside air and the heating elements. This is the key to strict atmospheric control.

This design allows processes to be run under vacuum, in an inert gas (like argon or nitrogen), or within a reactive gas atmosphere. Optional gas mixing systems provide even greater control for complex chemical processes.

High Efficiency and Compact Design

Compared to other furnace types of similar capacity, tube furnaces often have a smaller footprint and lower overall volume.

This efficiency translates to lower energy consumption, especially during long-term or continuous operation, saving significant operational costs over the equipment's lifespan.

Ease of Operation and Control

Modern tube furnaces are equipped with advanced digital controllers. These systems enable intelligent, programmable operation and often include features for remote monitoring and data logging.

This level of control simplifies complex heating profiles and enhances both the safety and performance of laboratory and factory processes.

Choosing the Right Furnace Configuration

The term "tube furnace" describes a category of equipment. The specific orientation and design—horizontal, vertical, or split—directly impact its ideal application.

The Horizontal Tube Furnace: For Ultimate Uniformity

Horizontal furnaces are the most common configuration and are considered the standard for achieving maximum thermal uniformity.

They are ideal for processing thermally sensitive parts that require the most consistent heat distribution possible, with some models reaching temperatures up to 1800°C.

The Vertical Tube Furnace: For Batch Processing & Space Saving

Vertical tube furnaces offer a more compact footprint, making them an excellent choice for labs where floor space is limited.

Their top-loading design simplifies the loading and unloading of samples, which is particularly convenient for batch processing and certain material handling procedures.

The Split Tube Furnace: For Complex Setups

The defining feature of a split tube furnace is its hinged body that can be opened. This provides unobstructed access to the work tube.

This design is essential when working with reaction vessels that have large flanges, multiple ports, or other fittings that would make it impossible to insert them into a standard, non-split furnace.

Understanding the Practical Considerations

While powerful, tube furnaces have operational realities that must be managed to ensure safety, longevity, and consistent performance.

Sample Handling and Throughput

Samples are typically placed in ceramic or metal "boats" and positioned within the hot zone using a long push rod. This manual process is perfect for research and development but may be a limiting factor for very high-volume, automated production.

Work Tube Limitations

The work tube is a critical component that is exposed to extreme conditions. Its material (e.g., quartz, alumina, silicon carbide) must be carefully selected to match the required temperature and chemical atmosphere. Tubes are effectively consumables that will require eventual replacement.

The Importance of Regular Maintenance

Like any high-temperature equipment, regular maintenance is crucial. Proactive care prevents unexpected downtime, ensures accurate temperature control, and is fundamental to maintaining operator safety.

Making the Right Choice for Your Process

Selecting the correct tube furnace configuration depends entirely on the specific goals of your thermal process.

- If your primary focus is ultimate thermal precision and atmospheric purity: A multi-zone horizontal tube furnace is the superior choice.

- If your primary focus is efficient batch processing or saving lab space: A vertical tube furnace provides convenience and a compact design.

- If your primary focus is working with complex reaction vessels or sealed tube assemblies: The accessibility of a split tube furnace is non-negotiable.

Choosing the right furnace configuration is the first step toward achieving reproducible, high-quality results in your thermal processing work.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Temperature Uniformity | Exceptional heat consistency along the heated zone | Reliable, repeatable material synthesis |

| Atmospheric Control | Sealed tube for vacuum, inert, or reactive gases | Processes sensitive to contamination |

| High Efficiency | Compact design with lower energy consumption | Long-term, cost-effective operation |

| Ease of Operation | Advanced digital controllers for programmable profiles | Simplified complex heating processes |

| Configuration Flexibility | Horizontal, vertical, or split-tube designs | Tailored solutions for specific lab needs |

Ready to enhance your lab's thermal processing capabilities? KINTEK specializes in high-performance tube furnaces and lab equipment, providing tailored solutions for your material synthesis, thermal testing, and research needs. Our experts will help you select the ideal horizontal, vertical, or split-tube configuration to ensure precise temperature control, atmospheric purity, and operational efficiency. Contact us today to discuss your requirements and achieve reproducible, high-quality results with KINTEK's reliable laboratory solutions!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What factors influence the general design of a tube furnace? Match Your Process with the Perfect System

- How does an alumina tube furnace with a controlled atmosphere simulate conditions in CSP environments? Master Accuracy.

- What is the role of corundum tubes in oxygen permeation testing? Ensure Integrity for Bi-doped Membranes

- What is the ceramic tube high temperature? From 1100°C to 1800°C, Choose the Right Material

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere