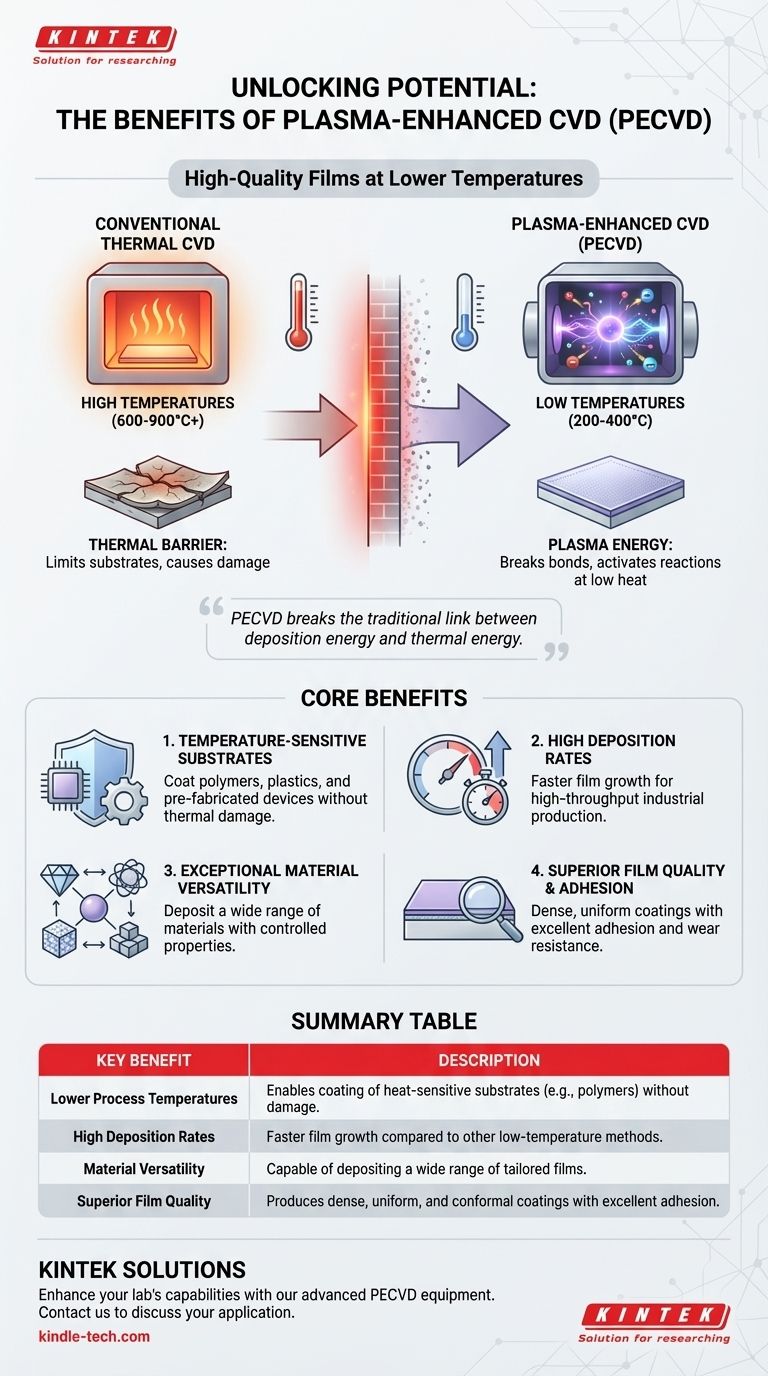

The primary advantage of Plasma-Enhanced Chemical Vapor Deposition (PECVD) is its ability to deposit high-quality, uniform films at significantly lower temperatures than conventional Chemical Vapor Deposition (CVD). This is achieved by using an energy-rich plasma to break down precursor gases, rather than relying solely on high heat. This fundamental difference unlocks high deposition rates and the ability to coat a much wider range of materials, including those sensitive to temperature.

PECVD breaks the traditional link between deposition energy and thermal energy. By using plasma to activate the chemical reactions, it allows for high-energy processes to occur in a low-temperature environment, which is the source of its most significant benefits.

How Plasma Redefines the Deposition Process

To understand the benefits of PECVD, it is essential to first understand the limitations it was designed to overcome.

The Thermal Barrier of Conventional CVD

Conventional thermal CVD requires very high temperatures, often exceeding 600-900°C. This heat provides the necessary activation energy for precursor gases to react and form a solid film on the substrate surface.

This high-temperature requirement severely limits the types of substrates that can be used. Materials like plastics, polymers, or many semiconductor devices with pre-existing metallic layers cannot withstand such heat without melting, warping, or degrading.

The Role of Plasma Energy

PECVD circumvents this thermal barrier by introducing energy in a different form: an electromagnetic field (typically radio frequency) that ignites a plasma.

This plasma is a partially ionized gas containing a mix of high-energy electrons, ions, and neutral radicals. The energetic electrons collide with the precursor gas molecules, breaking their chemical bonds and creating highly reactive species.

Result: A Low-Temperature, High-Energy System

These reactive species can then deposit onto the substrate and form a high-quality film without requiring high thermal energy. The bulk temperature of the process can be kept much lower, often in the 200-400°C range.

Essentially, plasma provides the activation energy that heat provides in conventional CVD. This creates a unique processing window that is both low-temperature and high-energy.

Core Benefits of the PECVD Method

This low-temperature, high-energy environment directly translates into several powerful advantages for materials engineering and manufacturing.

Deposition on Temperature-Sensitive Substrates

This is arguably the most critical benefit of PECVD. The ability to deposit durable, functional coatings on polymers, plastics, and fully fabricated semiconductor wafers without causing thermal damage opens up countless applications that are impossible with thermal CVD.

High Deposition Rates

The high density of reactive species generated by the plasma often leads to significantly faster film growth compared to other low-temperature methods. High deposition rates, sometimes reaching hundreds of micrometers per hour for specific materials like diamond films, make PECVD ideal for industrial production and high-throughput applications.

Exceptional Material Versatility

PECVD is not limited to a single class of material. It is a highly versatile technique capable of producing a wide range of films with controlled properties.

This includes elemental materials, alloys, glassy and amorphous films, and even highly structured polycrystalline or single-crystal materials like diamond. The process parameters can be tuned to precisely control the final microstructure.

Superior Film Quality and Adhesion

Despite the low temperatures, the energetic nature of the plasma process promotes excellent film adhesion to the substrate. It also enables the growth of dense, uniform, and conformal coatings that can evenly cover complex, non-flat surfaces. This results in films with excellent wear resistance, chemical resistance, and tailored electrical or thermal properties.

Understanding the Trade-offs

No technology is without its limitations. Being an effective advisor means acknowledging the trade-offs inherent in choosing PECVD.

Increased System Complexity

PECVD reactors are more complex than their thermal CVD counterparts. They require additional equipment, including RF or DC power generators, impedance matching networks, and more sophisticated vacuum systems, which can increase initial setup and maintenance costs.

Potential for Plasma-Induced Damage

The same high-energy ions that enable low-temperature deposition can, if not properly controlled, cause damage to the substrate surface or the growing film. This can be a concern in sensitive electronic applications, and process engineers must carefully tune plasma parameters to mitigate this risk.

Potential for Impurity Incorporation

The gases used to create the plasma (such as hydrogen or argon) can become incorporated into the growing film as impurities. While sometimes this is a deliberate effect (passivation), it can be an undesirable side effect that alters the film's properties compared to a purer film grown via high-temperature CVD.

Making the Right Choice for Your Application

Your choice between PECVD and another deposition method should be driven by the specific requirements of your substrate and desired film properties.

- If your primary focus is coating heat-sensitive substrates: PECVD is the definitive choice due to its fundamentally lower process temperatures.

- If your primary focus is achieving the highest possible film purity for a simple material: Conventional high-temperature CVD might be preferable, as it avoids potential plasma-related impurities and system complexity.

- If your primary focus is industrial throughput on large or complex parts: PECVD's combination of high deposition rates and conformal coating capabilities makes it a powerful manufacturing tool.

By decoupling the deposition reaction from high heat, PECVD provides a unique and powerful capability for modern materials science.

Summary Table:

| Key Benefit | Description |

|---|---|

| Lower Process Temperatures | Enables coating of heat-sensitive substrates (e.g., polymers, plastics) without damage. |

| High Deposition Rates | Faster film growth compared to other low-temperature methods, ideal for high-throughput production. |

| Material Versatility | Capable of depositing a wide range of films, from amorphous to polycrystalline, with tailored properties. |

| Superior Film Quality | Produces dense, uniform, and conformal coatings with excellent adhesion and wear resistance. |

Ready to enhance your lab's capabilities with Plasma-Enhanced CVD?

KINTEK specializes in providing advanced lab equipment and consumables tailored to your research and production needs. Whether you are working with temperature-sensitive substrates or require high-throughput, high-quality film deposition, our expertise can help you achieve superior results.

Contact us today to discuss how PECVD solutions from KINTEK can benefit your specific application and drive your projects forward.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What are the drawbacks of PECVD? Understanding the Trade-offs of Low-Temperature Deposition

- What is plasma enhanced CVD? Achieve High-Quality Thin Films at Lower Temperatures

- What is Plasma-enhanced CVD (PECVD)? The Critical Benefits for CMOS Fabrication and Thin Film Quality

- How long does DLC coating last? Unlock Extreme Durability for Your Components

- What does DLC coating do? Enhance Durability and Reduce Friction for Critical Components

- What are the advantageous properties of thin films deposited by PECVD? Enhance Your Device Reliability

- How does a rotating sample stage improve PECVD coatings? Achieve Uniformity for Porous Membranes

- What are the different types of plasma sources? A Guide to DC, RF, and Microwave Technologies