At its core, pyrolysis benefits the environment by fundamentally changing our relationship with waste. It is a thermochemical process that converts organic materials, such as biomass, plastics, and municipal solid waste, into valuable products. This transformation simultaneously reduces the burden on landfills, creates renewable energy sources, and decreases our dependence on virgin fossil fuels.

The true environmental value of pyrolysis lies in its ability to reframe "waste" as a resource. It is not merely a disposal method but a key technology for creating a circular economy, turning potential pollutants into fuel, chemicals, and a powerful tool for carbon sequestration.

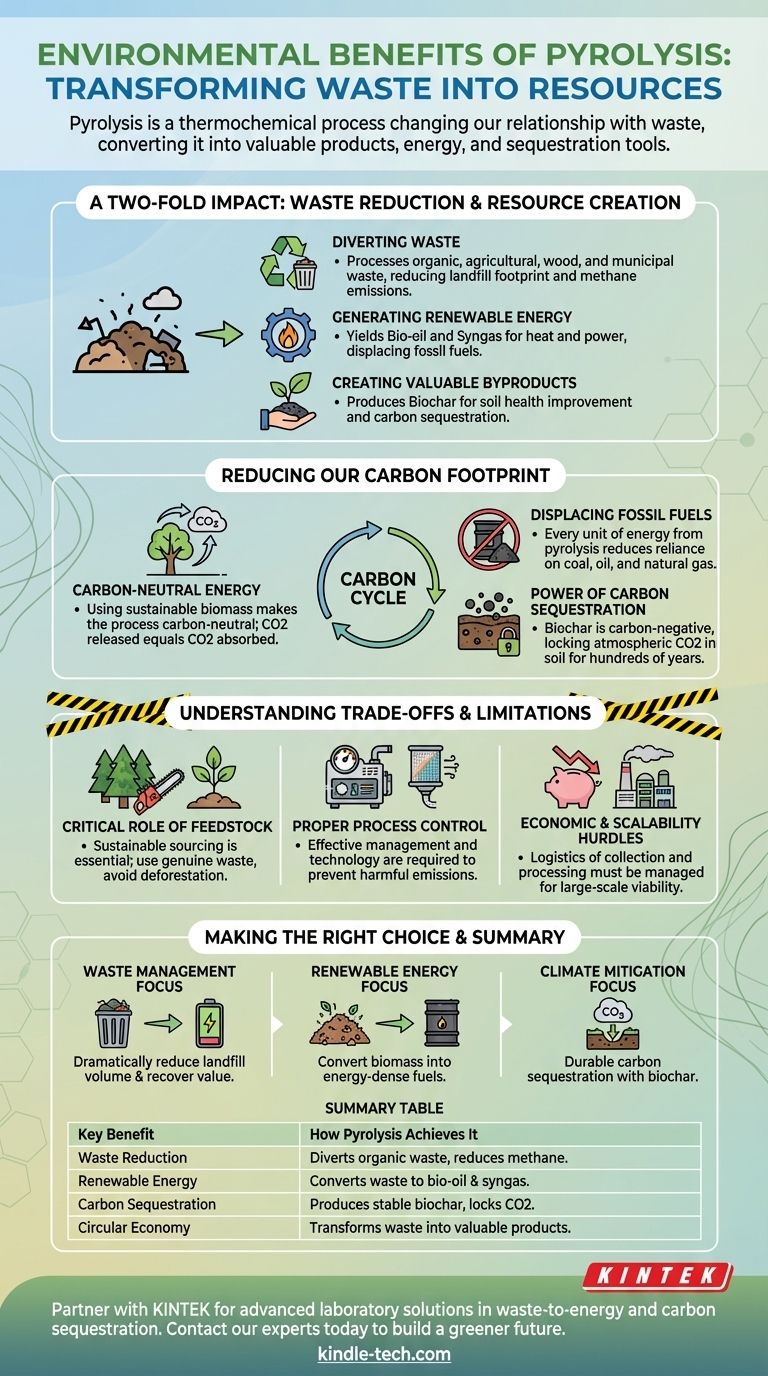

A Two-Fold Impact: Waste Reduction and Resource Creation

The most immediate environmental benefit of pyrolysis is its ability to tackle the dual problems of waste accumulation and resource depletion. It addresses both sides of the consumption lifecycle.

Diverting Waste from Landfills

Pyrolysis provides a highly effective way to process a wide range of organic waste materials. This includes agricultural residues, wood processing waste, and certain components of municipal solid waste that would otherwise occupy valuable landfill space.

By diverting this waste, we reduce the environmental footprint of landfills, which are significant sources of methane, a potent greenhouse gas.

Generating Renewable Energy

The process yields bio-oil and syngas, which are high-energy-density fuels. These can be used to generate heat and power, directly displacing the need for traditional fossil fuels.

This creates a self-sustaining energy loop, where waste can be used to power the very communities that produced it.

Creating Valuable Byproducts

Perhaps the most significant byproduct from an environmental standpoint is biochar. This stable, carbon-rich material is created from the solid residue of pyrolysis.

Biochar is not just a waste product; it is a valuable material used for improving soil health and, most importantly, for sequestering carbon.

Reducing Our Carbon Footprint

Beyond waste management, pyrolysis offers a direct pathway to reducing atmospheric carbon dioxide levels and mitigating climate change.

A Carbon-Neutral Energy Pathway

When pyrolysis uses sustainable biomass as a feedstock, the process can be considered carbon-neutral. The carbon dioxide released during the creation and use of its biofuels is equivalent to the amount the original biomass absorbed from the atmosphere during its growth.

Displacing Fossil Fuels

Every unit of energy generated from pyrolysis is one less unit that needs to be extracted and burned from fossil fuel sources like coal, oil, and natural gas. This directly reduces the net addition of greenhouse gases into the atmosphere and cuts down on associated pollution.

The Power of Carbon Sequestration

The creation of biochar makes pyrolysis a potentially carbon-negative technology. Biochar is a highly stable form of carbon that resists decomposition for hundreds or even thousands of years.

When this biochar is added to soil, the carbon it contains is effectively removed from the atmospheric cycle. This long-term storage, or sequestration, represents a powerful tool for actively drawing down atmospheric CO2.

Understanding the Trade-offs and Limitations

To maintain objectivity, it is critical to acknowledge that the environmental benefits of pyrolysis are not automatic. They depend heavily on responsible implementation.

The Critical Role of Feedstock Sourcing

The single greatest variable is the source of the organic material. Using biomass from unsustainable forestry practices can lead to deforestation and habitat destruction, negating the climate benefits.

The process is only as green as its inputs. Prioritizing genuine waste streams and sustainably managed biomass is essential.

The Need for Proper Process Control

Like any industrial process, poorly controlled pyrolysis can produce pollutants. Effective management and modern technology are required to ensure that the process is clean, efficient, and does not release harmful emissions into the environment.

Economic and Scalability Hurdles

While pyrolysis can be performed in small, remote locations, achieving economic viability at a large scale remains a challenge. The logistics of collecting, transporting, and processing feedstock must be carefully managed to ensure the system is both environmentally and economically sustainable.

Making the Right Choice for Your Goal

Pyrolysis is not a single solution but a flexible platform. How you apply it should depend on your primary environmental objective.

- If your primary focus is waste management: Pyrolysis is an excellent method to dramatically reduce landfill volume while recovering value from organic waste streams.

- If your primary focus is renewable energy production: The technology provides a reliable way to convert low-density, difficult-to-transport biomass into energy-dense liquid fuels and syngas.

- If your primary focus is climate change mitigation: The production and application of biochar offer one of the most promising and durable methods for long-term carbon sequestration.

Ultimately, pyrolysis empowers us to treat organic waste not as a liability to be buried, but as a valuable asset in the transition to a sustainable future.

Summary Table:

| Key Environmental Benefit | How Pyrolysis Achieves It |

|---|---|

| Waste Reduction | Diverts organic waste from landfills, reducing methane emissions and land use. |

| Renewable Energy | Converts waste into bio-oil and syngas, displacing fossil fuels. |

| Carbon Sequestration | Produces biochar, a stable carbon material that locks away CO2 in soil for centuries. |

| Circular Economy | Transforms waste streams into valuable products, closing the resource loop. |

Ready to integrate pyrolysis technology into your sustainability strategy?

At KINTEK, we specialize in providing advanced laboratory equipment and consumables to support your research and development in waste-to-energy and carbon sequestration technologies. Whether you are exploring feedstock efficiency, optimizing biochar production, or scaling up your processes, our solutions are designed to help you achieve precise, reliable, and sustainable results.

Let's build a greener future together. Contact our experts today to discuss how KINTEK can support your environmental innovation goals.

Visual Guide

Related Products

- Graphite Vacuum Continuous Graphitization Furnace

- Vertical Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How much temperature can graphite withstand? Unlock its true potential up to 3000°C

- Is graphite good in high temperature? Unlocking Its Extreme Heat Potential

- What is the temperature resistance of graphite? Unlocking Its High-Temp Potential in Your Lab

- How does graphite react to heat? Unlocking Its Unique High-Temperature Strengths

- What are the mechanical properties of graphite? Harnessing Rigidity and Managing Brittleness