The fundamental benefit of slow pyrolysis is its unparalleled ability to maximize the production of a stable, solid carbon product known as biochar. Unlike other thermal processes that prioritize energy generation, slow pyrolysis is deliberately controlled to convert biomass into a high-yield solid, making it a superior method for carbon sequestration and creating valuable agricultural products.

The core advantage isn't speed or energy output, but process control. Slow pyrolysis uses low temperatures and slow heating rates to deliberately favor the chemical reactions that produce high quantities of stable, solid biochar rather than liquid or gaseous fuels.

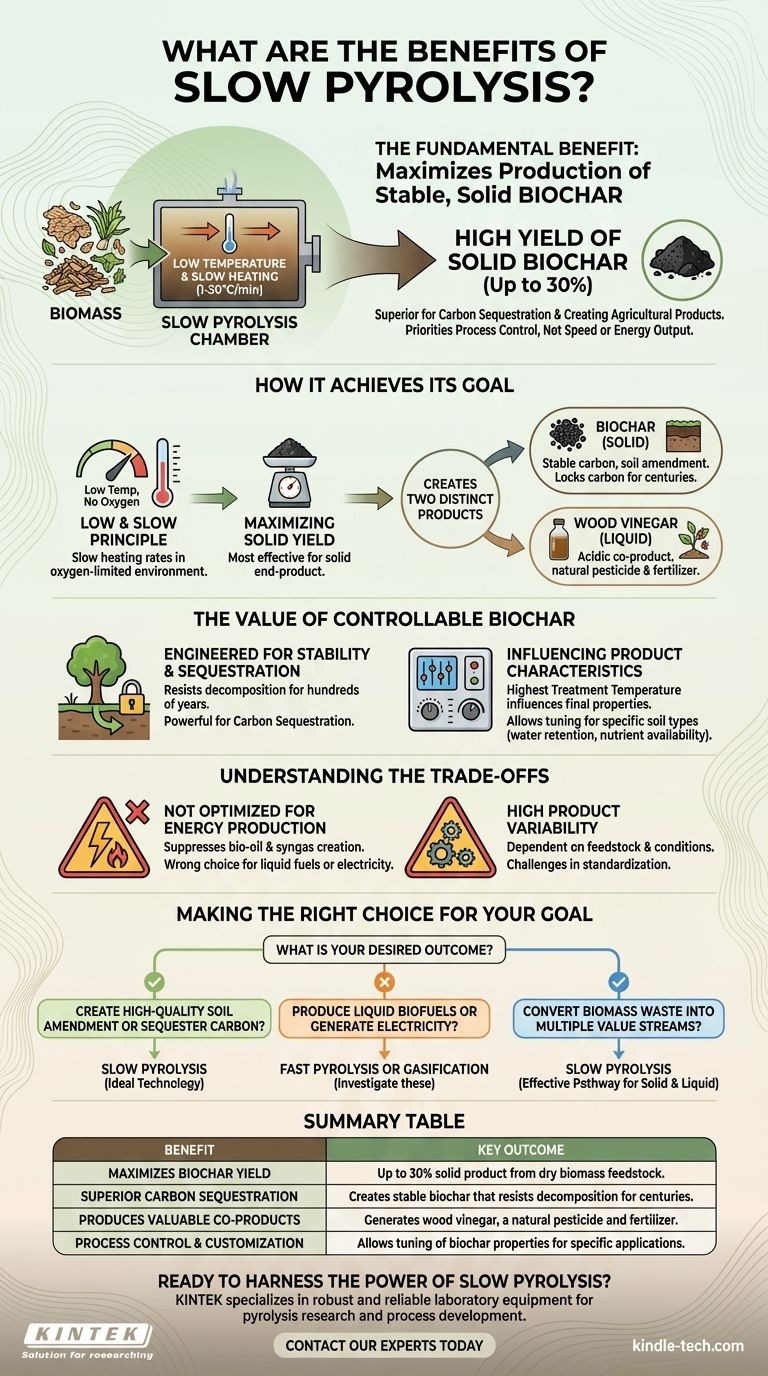

How Slow Pyrolysis Achieves Its Goal

Slow pyrolysis is a thermal decomposition process engineered for a specific outcome. Its operational parameters are the key to understanding its benefits.

The Core Principle: Low and Slow

The process is defined by its methodical pace. It involves heating biomass feedstock at slow heating rates (typically 1–30°C per minute) in an environment with limited or no oxygen.

This controlled, low-and-slow approach is fundamentally different from fast pyrolysis or gasification, which use high temperatures and rapid heating to maximize the yield of bio-oil or syngas for energy.

Maximizing Solid Product Yield

The primary objective and benefit of this method is the high yield of solid product. Under these conditions, biochar yields can reach up to 30% of the initial dry feedstock weight.

This makes it the most effective pyrolysis method when the desired end-product is a solid, not a liquid or gas.

Creating Two Distinct Products

Slow pyrolysis reliably creates two major outputs from the initial biomass:

- Biochar: A stable, carbon-rich solid (also called char or biocoal).

- Wood Vinegar: An acidic, aqueous liquid co-product (also known as pyroligneous acid).

The value of these products is the direct benefit of running the process. Biochar is a powerful soil amendment, while wood vinegar has applications as a natural pesticide and fertilizer.

The Value of Controllable Biochar

The main benefit of slow pyrolysis is realized through the unique and valuable properties of the biochar it creates.

Engineered for Stability and Sequestration

Because it is produced slowly, biochar is a highly stable form of carbon. When added to soil, it resists decomposition for hundreds or thousands of years, effectively locking carbon out of the atmosphere. This makes it a powerful tool for carbon sequestration.

Influencing Product Characteristics

The process offers significant control over the final product's quality. While factors like feedstock and vapor residence time matter, the highest treatment temperature has the greatest influence on the biochar’s final characteristics.

This allows producers to fine-tune the process to create specific types of biochar tailored for different applications, such as improving water retention in sandy soils or increasing nutrient availability in clay soils.

Understanding the Trade-offs

To choose the right process, you must understand its inherent limitations. Slow pyrolysis is a specialized tool, not a universal solution.

Not Optimized for Energy Production

If your goal is to produce liquid bio-oil or combustible syngas for energy generation, slow pyrolysis is the wrong choice. Its slow heating rates and lower temperatures intentionally suppress the reactions that create these products.

High Product Variability

The properties of the resulting biochar and wood vinegar are highly dependent on the initial feedstock and exact process conditions. This can make it difficult to create a perfectly standardized product, which presents challenges for defining market value and potential price.

Making the Right Choice for Your Goal

Selecting a thermal conversion technology depends entirely on your desired outcome.

- If your primary focus is creating a high-quality soil amendment or sequestering carbon: Slow pyrolysis is the ideal technology because it is specifically designed to maximize the yield of stable, solid biochar.

- If your primary focus is producing liquid biofuels or generating electricity: You should investigate fast pyrolysis or gasification, as these processes are optimized to produce bio-oil and syngas.

- If your primary focus is converting biomass waste into multiple value streams: Slow pyrolysis offers an effective pathway to transform a single input into two distinct and potentially marketable products: a solid and a liquid.

Ultimately, choosing slow pyrolysis is a strategic decision to prioritize the creation of a stable, valuable solid material over the immediate generation of energy.

Summary Table:

| Benefit | Key Outcome |

|---|---|

| Maximizes Biochar Yield | Up to 30% solid product from dry biomass feedstock. |

| Superior Carbon Sequestration | Creates stable biochar that resists decomposition for centuries. |

| Produces Valuable Co-Products | Generates wood vinegar, a natural pesticide and fertilizer. |

| Process Control & Customization | Allows tuning of biochar properties for specific applications (e.g., soil type). |

Ready to harness the power of slow pyrolysis for your biomass conversion or carbon sequestration project?

KINTEK specializes in providing robust and reliable laboratory equipment for pyrolysis research and process development. Whether you are optimizing biochar production, analyzing feedstock, or scaling your process, our solutions are designed to meet the precise needs of laboratories and research facilities.

Contact our experts today to discuss how KINTEK's lab equipment can help you achieve superior control and results in your pyrolysis projects.

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- Why are quartz tubes preferred for chromium powder combustion? Superior Heat Resistance & Optical Clarity

- What is the role of a tube furnace in the thermal treatment of argyrodite electrolytes? Master Ionic Conductivity

- What happens when quartz is heated? A Guide to Its Critical Phase Transitions and Uses