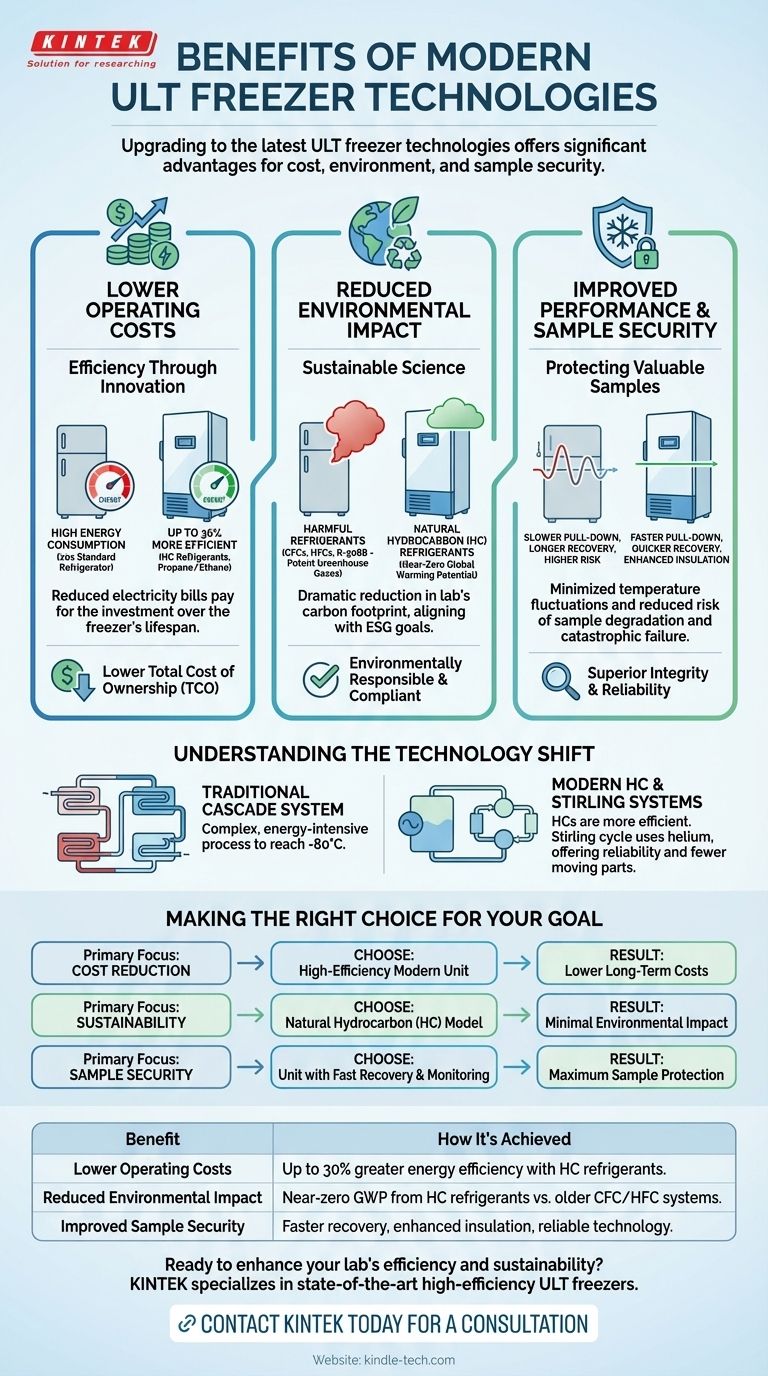

In short, staying updated with the latest ULT freezer technologies provides significant benefits in three key areas: lower long-term operating costs, a drastically reduced environmental footprint, and improved performance that enhances the security of your valuable samples. These are not minor upgrades, but fundamental improvements in efficiency and sustainability.

The decision to upgrade a ULT freezer is no longer just about replacing aging equipment. It's a strategic choice to shift from high-consumption, environmentally taxing systems to modern, efficient technology that directly benefits your budget and your sustainability goals.

The Core Problem: The Hidden Costs of Older Freezers

Older Ultra-Low Temperature (ULT) freezers are some of the most energy-intensive pieces of equipment in any laboratory. They represent a significant and often overlooked drain on operational budgets and environmental resources.

Extreme Energy Consumption

A traditional ULT freezer can consume an immense amount of electricity, sometimes as much as 20 times that of a standard household refrigerator. This is primarily due to older, less efficient cooling technologies.

These units run continuously to maintain temperatures of -80°C, placing a constant and heavy load on your facility's electrical system and budget.

Outdated and Harmful Refrigerants

Many older freezers rely on chlorofluorocarbon (CFC) or hydrofluorocarbon (HFC) refrigerants, such as R-508B. These are potent greenhouse gases that contribute significantly to global warming when released.

As environmental regulations become stricter, these refrigerants are being phased out, making older units both an environmental liability and potentially more difficult to service in the future.

How Modern Technologies Drive Key Benefits

The latest generation of ULT freezers addresses these problems directly with fundamentally different engineering. The improvements are not incremental; they are transformative.

Lowering Operating Costs Through Efficiency

The single biggest change is the move to new cooling systems. Modern freezers that use natural hydrocarbon (HC) refrigerants (like propane and ethane) can be up to 30% more energy-efficient than older CFC/HFC-based models.

This reduction in energy use translates directly into lower electricity bills, allowing the freezer to pay for its initial investment over its lifespan.

Reducing Environmental Impact

Hydrocarbon refrigerants are naturally occurring, non-toxic gases with a near-zero global warming potential. Switching to an HC freezer dramatically reduces your lab's carbon footprint.

This helps your organization meet its environmental, social, and governance (ESG) goals and positions your lab as a leader in sustainable science.

Improving Performance and Sample Security

"Improved performance" isn't just a marketing term. Modern units offer tangible benefits for sample integrity.

Newer systems often feature faster temperature pull-down times and quicker recovery after a door opening. This minimizes temperature fluctuations and reduces the risk of sample degradation. Enhanced insulation and more reliable compressor technology also decrease the risk of catastrophic failure.

Understanding the Technology Shift

To appreciate the benefits, it helps to understand the core technologies at play.

From Cascade to Efficient Cooling

Traditional ULT freezers use a cascade refrigeration system. This involves two separate cooling circuits that work in sequence to reach -80°C, which is a complex and energy-intensive process.

The Power of Hydrocarbon (HC) Refrigerants

Modern systems still often use a cascade design, but they replace synthetic refrigerants with natural hydrocarbons. These HCs are far more efficient at transferring thermal energy, allowing the compressors to do less work to achieve the same temperature.

Alternative Systems: Stirling Cycle

Some manufacturers have moved away from compressor-based systems entirely, adopting technologies like the Stirling cycle cooler. This engine uses helium gas in a sealed system, offering excellent reliability and efficiency with very few moving parts.

Understanding the Trade-offs

Adopting new technology always involves evaluating its costs and benefits objectively.

The Upfront Capital Cost

The most significant hurdle is the initial purchase price. A new, high-efficiency ULT freezer is a major capital expense.

However, this cost must be weighed against the total cost of ownership (TCO). The substantial energy savings of a modern unit can offset the higher initial price over several years.

Managing New Refrigerants

While natural hydrocarbon refrigerants are highly effective, they are also flammable. This is a managed and minimal risk, as modern freezers are engineered with robust safety features and use only a small, sealed charge of gas. All commercially available units are certified to meet strict safety standards.

Making the Right Choice for Your Goal

Your decision should be guided by your primary objective.

- If your primary focus is cost reduction: Calculate the total cost of ownership. A modern freezer's energy savings will significantly lower its long-term cost compared to a less expensive, inefficient model.

- If your primary focus is sustainability: Prioritize models that use natural hydrocarbon (HC) refrigerants to virtually eliminate your freezer's direct greenhouse gas impact.

- If your primary focus is sample security: Look for models with the best temperature recovery data and monitoring features, which are hallmarks of the latest generation of ULT freezers.

Ultimately, investing in a modern ULT freezer is a strategic move that strengthens your lab's financial health, environmental responsibility, and scientific integrity.

Summary Table:

| Key Benefit | How Modern ULT Freezers Achieve It |

|---|---|

| Lower Operating Costs | Up to 30% greater energy efficiency with natural hydrocarbon (HC) refrigerants. |

| Reduced Environmental Impact | Near-zero global warming potential (GWP) from HC refrigerants vs. older CFC/HFC systems. |

| Improved Sample Security | Faster temperature recovery, enhanced insulation, and more reliable compressor technology. |

Ready to enhance your lab's efficiency and sustainability?

Upgrading to a modern ULT freezer is a strategic investment that pays off in lower energy bills, a reduced carbon footprint, and superior protection for your valuable samples. At KINTEK, we specialize in providing state-of-the-art lab equipment, including the latest high-efficiency ULT freezers, to meet the evolving needs of laboratories like yours.

Let our experts help you find the perfect solution to achieve your cost-saving and sustainability goals.

Contact KINTEK today for a consultation and discover the right ULT freezer for your lab.

Visual Guide

Related Products

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 108L Vertical Ultra Low Temperature ULT Freezer

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 308L Precision Ultra Low Temperature Freezer for Laboratory Applications

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

People Also Ask

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C