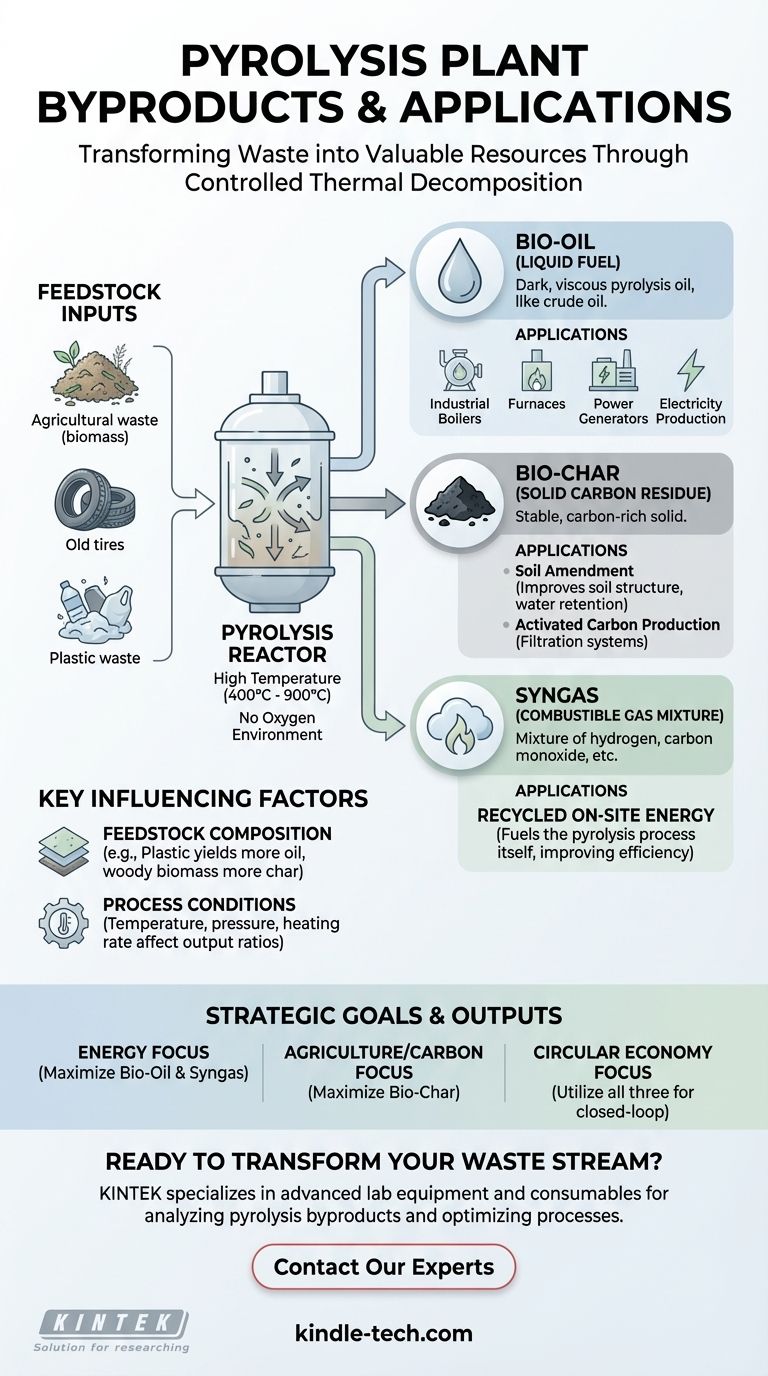

The primary byproducts of a pyrolysis plant are a versatile trio of resources: a liquid fuel known as bio-oil, a solid carbon-rich material called bio-char, and a combustible gas mixture referred to as syngas. These outputs are the result of a thermochemical process that breaks down organic materials like biomass, plastics, or old tires in a high-temperature, oxygen-free environment.

Pyrolysis should not be viewed as simple waste disposal. It is a sophisticated conversion technology that transforms low-value organic waste into distinct, marketable products with applications in energy, agriculture, and industry.

How Pyrolysis Creates Value from Waste

To understand the byproducts, you must first understand the process. Pyrolysis is fundamentally about controlled thermal decomposition, not burning.

The Core Process: Heating Without Oxygen

A pyrolysis plant feeds organic materials (feedstock) into a sealed reactor. This reactor is then heated to very high temperatures, typically between 400°C and 900°C.

Crucially, this occurs in an environment with little to no oxygen. Instead of combusting, the intense heat breaks the complex chemical bonds within the feedstock, deconstructing it into simpler, more stable components: the liquid, solid, and gas byproducts.

The Role of Feedstock

The specific type of organic material used as feedstock is critical. Common inputs include agricultural waste (biomass), scrap tires, and various types of plastic.

The nature of the feedstock directly influences the ratio and quality of the final byproducts.

A Detailed Look at the Byproducts

Each of the three primary outputs has its own characteristics and commercial applications.

Bio-Oil: The Liquid Fuel

This dark, viscous liquid is sometimes called pyrolysis oil. It is a complex mixture of organic compounds and can be thought of as a type of crude oil.

Its primary application is as an industrial fuel. Bio-oil can be used in boilers, furnaces, and generators across industries like steel manufacturing, ceramics, chemical plants, or to produce electricity.

Bio-Char: The Solid Carbon Residue

Bio-char is the stable, carbon-rich solid that remains after the volatile components have been driven off as gas and liquid. It is similar in appearance to charcoal.

This material has significant value as a soil amendment, improving water retention and soil structure. It also serves as a high-quality feedstock for producing activated carbon, which is used in filtration systems.

Syngas: The Recycled Energy Source

Syngas, or synthesis gas, is a mixture of combustible gases (primarily hydrogen and carbon monoxide). This byproduct is often captured and recycled within the plant itself.

It is typically used as a fuel source to provide the heat required for the pyrolysis reactor, making the entire process more energy-efficient and self-sustaining.

Understanding the Key Considerations

While the process is straightforward in principle, the results are highly variable and depend on careful operational control.

Feedstock Determines Output

The specific composition of your feedstock is the single most important factor. For example, pyrolyzing plastic waste tends to yield a higher percentage of bio-oil, while woody biomass will produce more bio-char.

Process Conditions Matter

The final product yields are also highly sensitive to operational parameters. Temperature, pressure, and the rate at which the feedstock is heated all impact whether you produce more oil, char, or gas.

The Importance of Emission Control

A modern, responsible pyrolysis plant is more than just a reactor. It includes a comprehensive emission cleaning line to treat and purify any exhaust gases before they are released, ensuring the process meets environmental standards.

Aligning Pyrolysis Output with Your Goal

The byproducts you prioritize will depend entirely on your strategic objective.

- If your primary focus is energy generation: Your goal is to maximize the yield of high-quality bio-oil and syngas, often achieved using feedstocks like plastics and tires.

- If your primary focus is agriculture or carbon sequestration: Bio-char is the key product, which is typically maximized by processing woody biomass at specific temperatures.

- If your primary focus is circular economy solutions: The ideal is to find a valuable application for all three byproducts, creating a closed-loop system with minimal waste and maximum economic return.

Pyrolysis transforms the concept of waste into a valuable opportunity for resource recovery.

Summary Table:

| Byproduct | Type | Primary Applications |

|---|---|---|

| Bio-Oil | Liquid Fuel | Industrial heating, electricity generation |

| Bio-Char | Solid Carbon | Soil amendment, activated carbon production |

| Syngas | Combustible Gas | On-site energy for the pyrolysis process |

Ready to transform your waste stream into profitable resources?

KINTEK specializes in advanced lab equipment and consumables for analyzing pyrolysis processes and byproducts. Whether you are a researcher optimizing bio-oil yield or an engineer testing bio-char for soil enhancement, our precise tools help you validate product quality and improve efficiency.

Let's build your sustainable solution together. Contact our experts today to discuss your specific laboratory needs!

Visual Guide

Related Products

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Laboratory Hybrid Tissue Grinding Mill

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

People Also Ask

- What role does a high-pressure reactor play in the hydrodeoxygenation (HDO) of bio-oil? Drive Deep Fuel Upgrading

- What is the function of a PTFE-lined hydrothermal autoclave in cys-CDs synthesis? Achieve High-Purity Carbon Dots

- What role does a PTFE-lined stainless steel autoclave play in the synthesis of BiOBr precursor nanosheets?

- What are the technical characteristics of PTFE (Teflon) lined hydrothermal reactors? Comparing α-ZrP Synthesis Methods

- What is the advantage of using high-pressure hydrothermal reactors to treat biomass waste? Efficient Resource Recovery