To characterize graphene, a suite of specialized techniques is used, with each providing a different piece of the puzzle. The primary methods include Raman spectroscopy to assess layer count and quality, electron microscopy (SEM and TEM) to visualize surface and internal structures, X-ray spectroscopy to determine chemical states, and atomic force microscopy (AFM) to measure local properties.

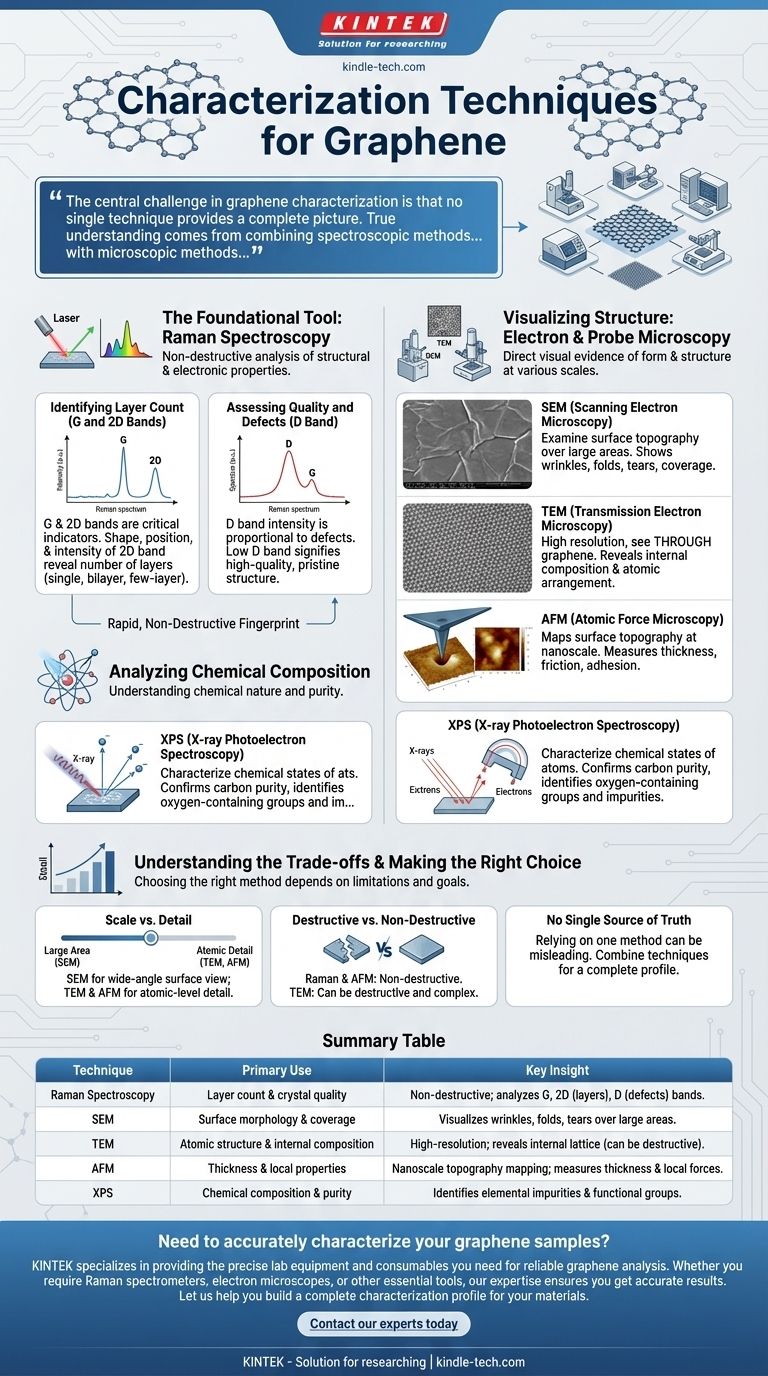

The central challenge in graphene characterization is that no single technique provides a complete picture. True understanding comes from combining spectroscopic methods that reveal quality and layer count with microscopic methods that visualize the physical structure.

The Foundational Tool: Raman Spectroscopy

Raman spectroscopy is arguably the most important, rapid, and non-destructive technique for analyzing graphene. It uses scattered light to provide a fingerprint of the material's structural and electronic properties.

Identifying Layer Count (G and 2D Bands)

The G band (around 1587 cm⁻¹) and the 2D band are critical indicators. The shape, position, and intensity of the 2D band, in particular, are highly sensitive to the number of graphene layers, allowing for a clear distinction between single-layer, bilayer, and few-layer samples.

Assessing Quality and Defects (D Band)

The presence and intensity of the D band are directly proportional to the number of defects or deformities in the graphene's honeycomb lattice. A low-intensity D band signifies a high-quality, pristine crystal structure, which is crucial for high-performance electronic applications.

Visualizing Structure: Electron & Probe Microscopy

While spectroscopy provides data about quality, microscopy provides direct visual evidence of the graphene's form and structure at various scales.

Examining Surface Topography (SEM)

Scanning Electron Microscopy (SEM) is used to examine the surface of the graphene sample over relatively large areas. It provides valuable information about wrinkles, folds, tears, and overall coverage on a substrate.

Revealing Internal Composition (TEM)

Transmission Electron Microscopy (TEM) offers much higher resolution, allowing you to see through the graphene. This technique provides fine details about the internal composition and atomic arrangement of the carbon atoms in the lattice.

Measuring Local Properties (AFM)

Atomic Force Microscopy (AFM) maps the surface topography at the nanoscale, making it excellent for precisely measuring the thickness of a graphene flake. It can also be adapted to measure local properties like friction, adhesion, and magnetic fields.

Analyzing Chemical Composition

Beyond physical structure, understanding the chemical nature of the graphene, especially if it has been functionalized or if impurities are a concern, is essential.

Characterizing Chemical States (X-ray Spectroscopy)

Techniques like X-ray Photoelectron Spectroscopy (XPS) are used to characterize the chemical states of the atoms within the sample. This can confirm the purity of the carbon lattice and identify any oxygen-containing functional groups or other elemental impurities.

Understanding the Trade-offs

Choosing the right characterization method requires understanding its limitations and what it is designed to measure.

Scale vs. Detail

SEM provides a wide-angle view of the material's surface morphology, while TEM and AFM zoom in to provide atomic-level detail. The choice depends on whether you need to assess large-area uniformity or atomic-scale perfection.

Destructive vs. Non-Destructive

Raman spectroscopy and AFM are generally non-destructive, meaning the sample can be used for further experiments. In contrast, sample preparation for TEM can be destructive and complex.

No Single Source of Truth

A perfect Raman spectrum might indicate high crystal quality in one spot, but an SEM image might reveal that the overall film is discontinuous. Relying on a single method can lead to an incomplete and potentially misleading conclusion about the material's overall quality.

Making the Right Choice for Your Goal

The optimal characterization strategy depends entirely on the information you need to obtain about your graphene sample.

- If your primary focus is verifying layer count and crystal quality: Raman spectroscopy is your essential first step for its speed and accuracy.

- If your primary focus is visualizing large-area surface coverage and morphology: Use Scanning Electron Microscopy (SEM) to get a comprehensive overview.

- If your primary focus is confirming atomic structure and internal integrity: Transmission Electron Microscopy (TEM) is the definitive tool.

- If your primary focus is analyzing chemical purity or functionalization: Use a method like X-ray Photoelectron Spectroscopy (XPS).

Ultimately, a comprehensive characterization relies on intelligently combining these techniques to build a complete and reliable profile of your material.

Summary Table:

| Technique | Primary Use | Key Insight |

|---|---|---|

| Raman Spectroscopy | Layer count & crystal quality | Non-destructive; analyzes G & 2D bands for layers, D band for defects. |

| SEM (Scanning Electron Microscopy) | Surface morphology & coverage | Visualizes wrinkles, folds, and tears over large areas. |

| TEM (Transmission Electron Microscopy) | Atomic structure & internal composition | High-resolution; reveals internal lattice arrangement (can be destructive). |

| AFM (Atomic Force Microscopy) | Thickness & local properties | Nanoscale topography mapping; measures thickness and local forces. |

| XPS (X-ray Photoelectron Spectroscopy) | Chemical composition & purity | Identifies elemental impurities and functional groups. |

Need to accurately characterize your graphene samples?

KINTEK specializes in providing the precise lab equipment and consumables you need for reliable graphene analysis. Whether you require Raman spectrometers for quality control, electron microscopes for structural imaging, or other essential tools, our expertise ensures you get accurate results.

Let us help you build a complete characterization profile for your materials. Contact our experts today to discuss your specific laboratory requirements!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition