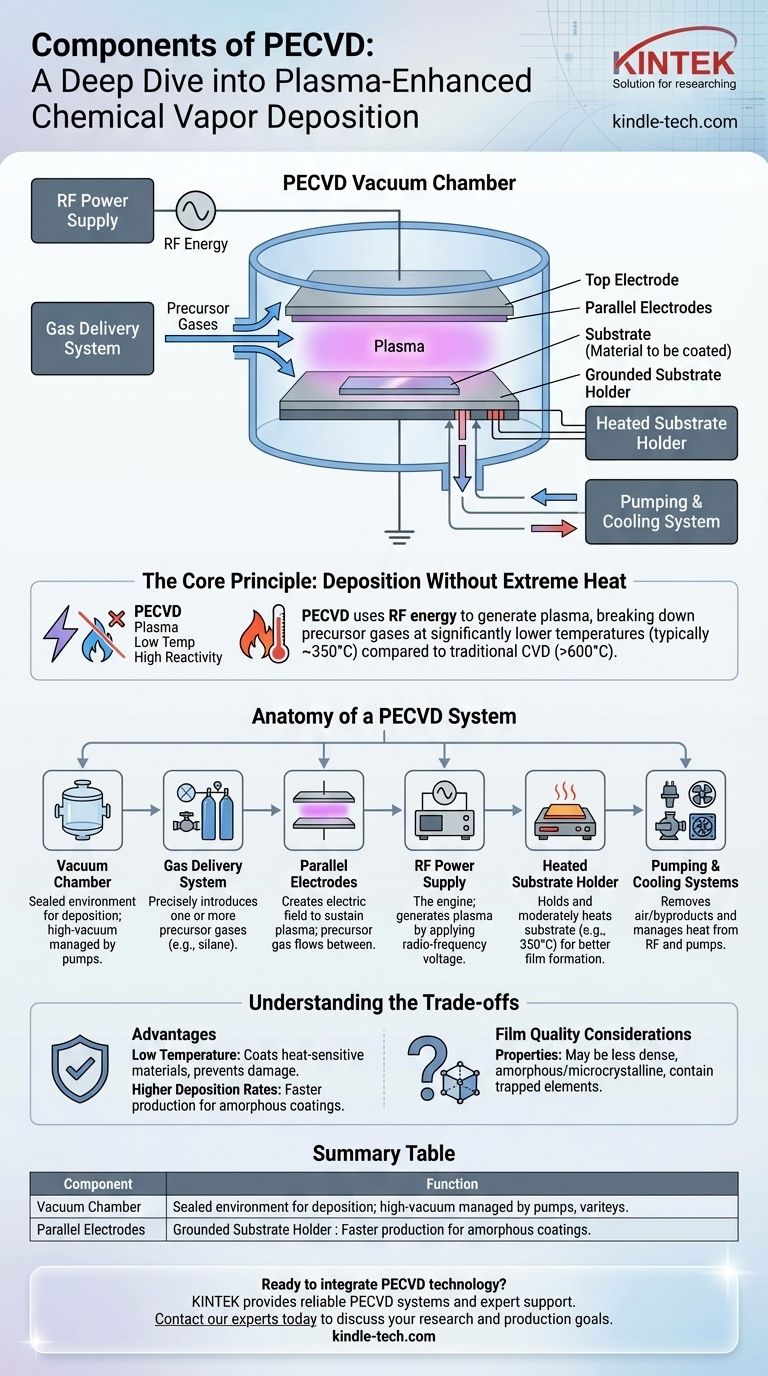

At its core, a PECVD system is composed of a vacuum chamber containing parallel electrodes, a gas delivery system to introduce precursor chemicals, a radio frequency (RF) power supply to generate plasma, and a heated substrate holder where the thin film is deposited. These components work in a high-vacuum environment, managed by a system of pumps and temperature controls.

Plasma-Enhanced Chemical Vapor Deposition (PECVD) is not just a single piece of equipment, but an integrated system. Its primary purpose is to use the energy of a plasma, rather than high heat, to drive chemical reactions that form a thin, solid film on a substrate.

The Core Principle: Deposition Without Extreme Heat

PECVD is a process for creating exceptionally thin layers of material, often on sensitive electronic components like semiconductors. Its defining feature is the use of plasma to enable reactions at much lower temperatures than traditional methods.

What is Plasma?

Plasma is often called the fourth state of matter. It is a gas that has been energized to the point where its atoms are ionized, creating a mix of charged ions and free electrons.

This energized state is highly reactive. In a PECVD system, the plasma has enough energy to break down stable precursor gases into reactive radicals, which are the building blocks for the new film.

How Plasma Enables Low-Temperature Deposition

Traditional Chemical Vapor Deposition (CVD) relies on very high temperatures (often >600°C) to provide the thermal energy needed to break chemical bonds and initiate deposition.

PECVD replaces most of that thermal energy with electrical energy from an RF power supply. The plasma does the heavy lifting of breaking down the precursor gases, allowing the deposition to occur at significantly lower temperatures, typically around 350°C.

Anatomy of a PECVD System

Each component of a PECVD system plays a critical role in controlling the environment and the chemical reaction needed to build the film layer by layer.

The Vacuum Chamber

This is the sealed enclosure where the entire deposition process takes place. It is connected to a pumping system to create a high-vacuum environment, which is essential for removing contaminants and controlling the pressure of the reactant gases.

The Gas Delivery System

This system, often using mass flow controllers, precisely introduces one or more precursor gases into the vacuum chamber. These gases contain the chemical elements that will make up the final film (e.g., silane gas to deposit a silicon film).

Parallel Electrodes

Inside the chamber, two parallel plates serve as the electrodes. One electrode is grounded and typically serves as the substrate holder, while the other is connected to the RF power supply. The precursor gas flows between these plates.

The RF Power Supply

This is the engine of the process. It applies a radio-frequency alternating voltage to one of the electrodes. This rapidly oscillating electric field energizes the precursor gas, stripping electrons from atoms and igniting the plasma between the plates.

The Substrate and Heater

The material to be coated, known as the substrate, is placed on one of the electrodes. This electrode is often heated to a moderate temperature. This heating helps remove surface impurities and gives the deposited atoms enough mobility to form a dense, uniform film.

Pumping and Cooling Systems

A high-vacuum pump removes air and reaction byproducts from the chamber. A separate water cooling system is often required to manage the heat generated by the pumps and the RF power supply, ensuring stable operation.

Understanding the Trade-offs

While powerful, PECVD is not a universal solution. Its primary advantage—low temperature—also influences the characteristics of the final film.

The Advantage of Low Temperature

The main benefit of PECVD is its ability to coat materials that cannot withstand high heat. This prevents thermal damage to sensitive electronic components, reduces warping or stress in the substrate, and minimizes unwanted diffusion between material layers.

Higher Deposition Rates

For certain types of films, particularly amorphous (non-crystalline) materials, PECVD can deposit material much faster than higher-temperature processes. This is a significant advantage in manufacturing environments where throughput is critical.

Film Quality Considerations

The films produced by PECVD can have different properties than those from high-temperature methods. They may be less dense or contain trapped elements (like hydrogen from a precursor gas), which can affect their electrical or mechanical properties. The films are often amorphous or microcrystalline rather than fully crystalline.

Making the Right Choice for Your Goal

Understanding the components and principles of PECVD allows you to decide when it is the appropriate tool for a fabrication challenge.

- If your primary focus is depositing on heat-sensitive materials: PECVD is the superior choice because its plasma-based process avoids the high thermal budget of other methods.

- If your primary focus is achieving the highest possible film purity and crystalline quality: A higher-temperature process like Low-Pressure CVD (LPCVD) may be more suitable, assuming your substrate can tolerate the heat.

- If your primary focus is the rapid production of amorphous coatings: PECVD offers a clear advantage in deposition speed and throughput for materials like amorphous silicon or silicon nitride.

By replacing extreme heat with the controlled energy of a plasma, PECVD provides a versatile and essential tool for modern materials engineering.

Summary Table:

| Component | Primary Function |

|---|---|

| Vacuum Chamber | Sealed environment for the deposition process. |

| Gas Delivery System | Precisely introduces precursor gases. |

| RF Power Supply | Generates plasma to energize the gases. |

| Parallel Electrodes | Creates the electric field to sustain the plasma. |

| Heated Substrate Holder | Holds and moderately heats the material being coated. |

| Pumping System | Maintains the required high-vacuum environment. |

Ready to integrate PECVD technology into your lab's workflow?

KINTEK specializes in high-quality lab equipment and consumables, providing reliable PECVD systems and expert support to meet your specific research and production goals. Whether you are working with sensitive semiconductors or require rapid deposition of amorphous coatings, our solutions are designed to enhance your capabilities and efficiency.

Contact our experts today to discuss how a KINTEK PECVD system can benefit your laboratory.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition