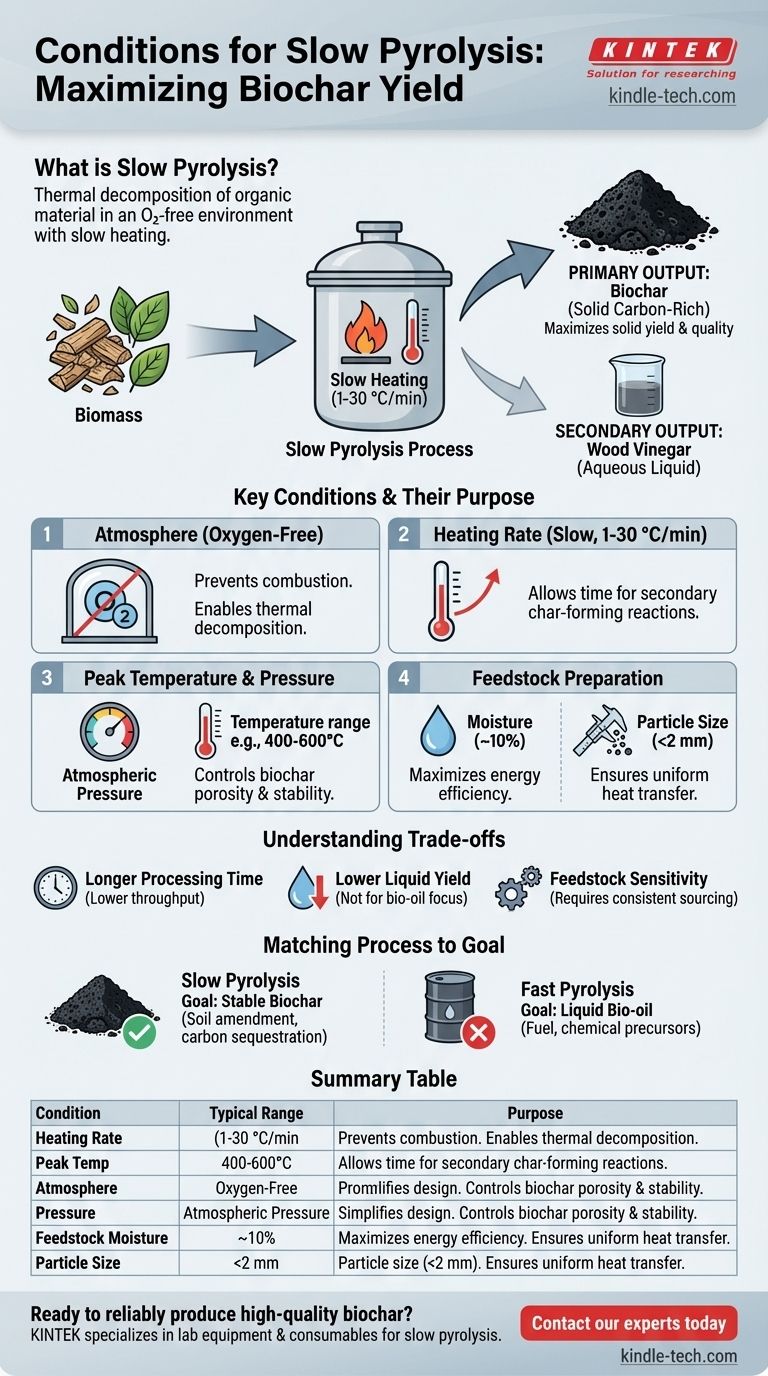

Slow pyrolysis is a thermal decomposition process defined by a specific set of controlled conditions. At its core, it involves gradually heating organic material at a slow rate (typically 1-30 °C per minute) in an oxygen-free environment to a target temperature, usually under atmospheric pressure.

The specific conditions of slow pyrolysis are not arbitrary; they are deliberately engineered to maximize the yield and quality of the solid product, biochar, by giving the material sufficient time to undergo secondary char-forming reactions.

The Goal of Slow Pyrolysis: Maximizing Biochar

Slow pyrolysis is fundamentally a modern, controlled version of carbonization—a process used for centuries to make charcoal. The entire methodology is optimized to convert the bulk of the biomass into a stable, carbon-rich solid.

Prioritizing the Solid Product

The slow heating rate is the key differentiator. Unlike fast pyrolysis, which uses rapid heating to "crack" biomass into liquid bio-oil, slow pyrolysis allows volatile gases to react and polymerize, forming additional layers of char on the solid material.

This process intentionally minimizes the yield of liquids and volatile gases to favor the creation of a high-quality, porous biochar.

The Two Major Outputs

The primary product is solid char (also known as biochar or biocoal), which can make up a significant portion of the initial feedstock's mass.

A secondary, lower-yield product is an aqueous liquid often called wood vinegar, which is condensed from the limited amount of vapor produced.

The Core Conditions and Their Purpose

Each condition in slow pyrolysis serves a distinct purpose, and mastering them is essential for achieving the desired outcome. The main factors include the atmospheric environment, heating rate, feedstock preparation, and temperature.

An Oxygen-Free Environment

The process must occur in an oxygen-limited or oxygen-free atmosphere. The absence of oxygen is critical because it prevents combustion (burning).

Instead of burning, the feedstock undergoes thermal decomposition, where heat alone breaks down the complex organic molecules.

The Slow Heating Rate

The defining characteristic is the slow heating rate, typically between 1 and 30 °C per minute. This gradual temperature increase provides a long residence time for the material within the reactor.

This extended time is crucial for allowing the secondary reactions that increase char yield and quality.

Peak Temperature and Pressure

The final or peak temperature affects the properties of the resulting biochar. Different temperatures can alter its porosity, surface area, and chemical stability.

The process is almost always carried out at atmospheric pressure, which simplifies reactor design and reduces operational costs.

The Importance of Feedstock Preparation

The state of the raw material, or feedstock, is just as important as the reactor conditions. Improper preparation can lead to an inefficient process and a low-quality product.

Controlling Moisture Content

The ideal feedstock moisture content is around 10%. Material that is too wet requires excessive energy to evaporate the water before pyrolysis can even begin.

Conversely, overly dry material can create excessive dust, posing operational challenges.

Reducing Particle Size

For efficient and uniform heat transfer, the feedstock must be reduced to a consistent, small particle size, often up to 2 mm.

This ensures that every particle heats at the same rate, preventing some parts from being under-processed while others are over-processed.

Understanding the Trade-offs

While effective for biochar production, the deliberate nature of slow pyrolysis comes with inherent trade-offs that must be considered.

Longer Processing Time

As the name implies, the process is slow. The long residence times required mean lower throughput compared to faster thermal conversion technologies, which can impact the overall scale of an operation.

Lower Liquid Yield

If your goal is to produce liquid bio-oil for use as a fuel or chemical precursor, slow pyrolysis is the wrong choice. Its conditions are explicitly designed to minimize liquid production.

Feedstock Sensitivity

The final quality and yield of the biochar are highly dependent on both the type of feedstock used and the precise control of the process conditions. This requires careful material sourcing and consistent operational management.

Matching the Process to Your Goal

Choosing the right thermal conversion technology depends entirely on your desired end product.

- If your primary focus is producing a stable, high-carbon solid (biochar) for soil amendment or carbon sequestration: Slow pyrolysis is the ideal method due to its high and controllable char yield.

- If your primary focus is maximizing liquid bio-oil for fuel or chemical production: You should investigate fast pyrolysis, as its rapid heating rates are designed to favor liquid products.

- If you are working with high-moisture feedstocks like sludge or food waste: A significant pre-drying step is a non-negotiable prerequisite for effective slow pyrolysis.

By deliberately controlling these conditions, you can steer the thermal decomposition of biomass to reliably produce a high-quality, valuable solid product.

Summary Table:

| Condition | Typical Range | Purpose |

|---|---|---|

| Heating Rate | 1-30 °C / minute | Allows time for secondary char-forming reactions |

| Peak Temperature | Varies (e.g., 400-600°C) | Controls biochar properties (porosity, stability) |

| Atmosphere | Oxygen-free | Prevents combustion, enables thermal decomposition |

| Pressure | Atmospheric | Simplifies reactor design and operation |

| Feedstock Moisture | ~10% | Maximizes energy efficiency |

| Particle Size | Up to 2 mm | Ensures uniform heat transfer |

Ready to reliably produce high-quality biochar?

The precise control of slow pyrolysis conditions is key to your success. KINTEK specializes in the lab equipment and consumables needed to master this process, from reactors to feedstock preparation tools. Our expertise helps you optimize for maximum biochar yield and quality, ensuring your research or production goals are met.

Contact our experts today to discuss how KINTEK's solutions can support your specific biomass conversion projects.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Non Consumable Vacuum Arc Induction Melting Furnace

- Spark Plasma Sintering Furnace SPS Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

People Also Ask

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process