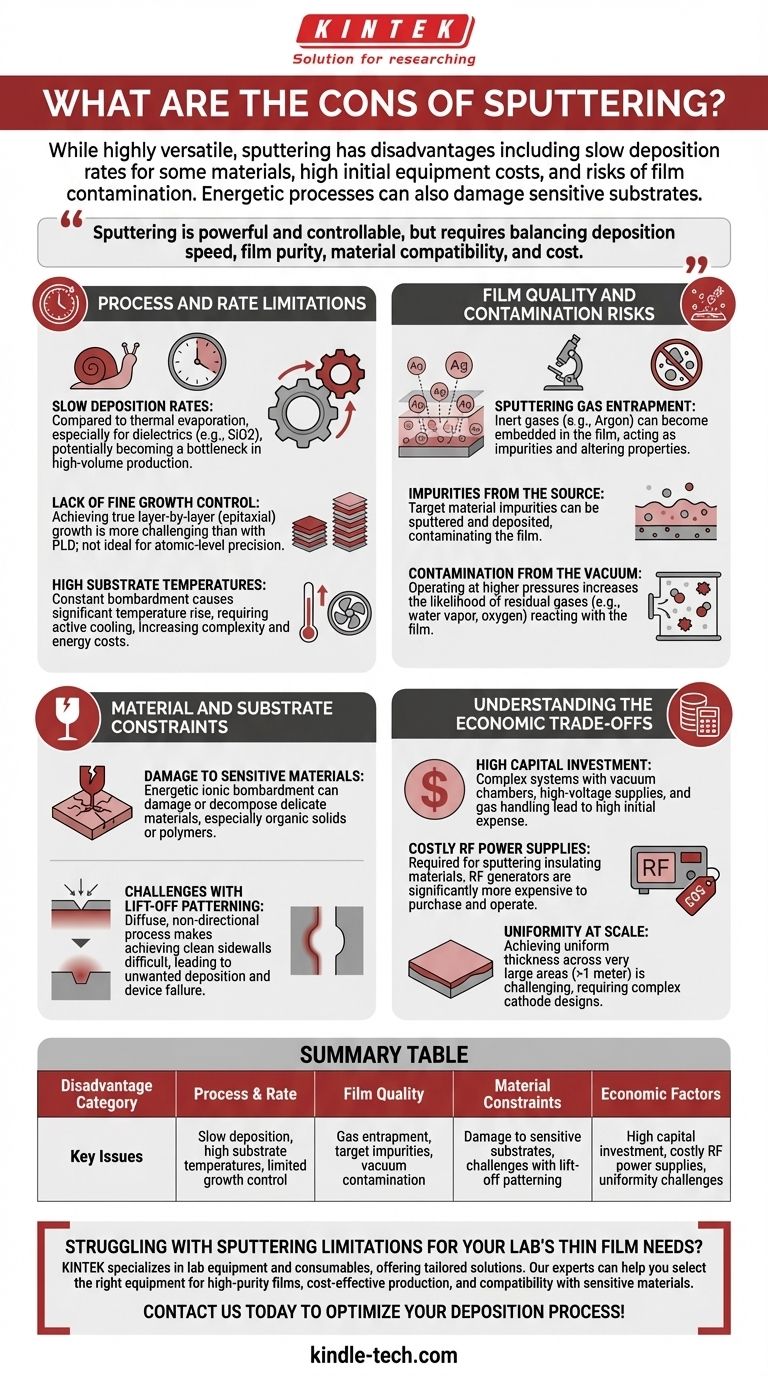

While highly versatile, the primary disadvantages of sputtering are its relatively slow deposition rates for certain materials, high initial equipment costs, and inherent risks of film contamination. The energetic nature of the process can also damage sensitive substrates or materials.

Sputtering is a powerful and controllable deposition method, but it is not without significant trade-offs. Its main drawbacks stem from the physics of ionic bombardment and the vacuum environment, creating a delicate balance between deposition speed, film purity, material compatibility, and overall cost.

Process and Rate Limitations

Sputtering is a physical process, and its mechanics impose several operational constraints that can impact manufacturing throughput and precision.

Slow Deposition Rates

Compared to thermal evaporation, sputtering can be a much slower process, especially for certain materials like dielectrics (e.g., SiO2). This can be a significant bottleneck in high-volume production environments where cycle time is critical.

Lack of Fine Growth Control

Achieving true layer-by-layer (epitaxial) growth is more challenging with sputtering than with techniques like Pulsed Laser Deposition (PLD). While sputtering offers good thickness control, it is not the ideal method for applications requiring atomic-level precision.

High Substrate Temperatures

The constant bombardment of particles can cause the substrate temperature to rise significantly. This requires active cooling systems, which add complexity, increase energy costs, and can decrease overall production rates.

Film Quality and Contamination Risks

The quality of a sputtered film is highly dependent on the process environment, which introduces several potential sources of contamination.

Sputtering Gas Entrapment

The inert gases used to create the plasma (typically Argon) can become embedded or entrapped within the growing thin film. These trapped gas atoms act as impurities and can alter the film's mechanical or electrical properties.

Impurities from the Source

The source material, or target, is never perfectly pure. Impurities within the target can be sputtered along with the desired material and deposited onto the substrate, contaminating the final film.

Contamination from the Vacuum

Sputtering often operates at a higher pressure (a poorer vacuum) than processes like evaporation. This increases the likelihood that residual gases in the chamber (like water vapor or oxygen) will react with or be incorporated into the film.

Material and Substrate Constraints

The high-energy nature of sputtering makes it unsuitable for certain types of materials and fabrication processes.

Damage to Sensitive Materials

The energetic ionic bombardment can easily damage or decompose delicate materials. This is particularly true for organic solids or polymers, which may not withstand the sputtering process.

Challenges with Lift-Off Patterning

"Lift-off" is a common technique for patterning thin films. However, sputtering is a diffuse, non-directional process, which makes achieving the clean, sharp sidewalls required for successful lift-off very difficult. This can lead to unwanted film deposition on the sidewalls of the pattern, causing device failure.

Understanding the Economic Trade-offs

Beyond the technical limitations, sputtering involves significant financial and operational considerations.

High Capital Investment

Sputtering systems are complex machines that require sophisticated vacuum chambers, high-voltage power supplies, and gas handling systems. This results in a high initial capital expense compared to simpler deposition methods.

Costly RF Power Supplies

To sputter electrically insulating materials, a Radio Frequency (RF) power supply is required instead of a simpler DC source. RF generators are significantly more expensive to purchase and operate.

Uniformity at Scale

While excellent for smaller substrates, achieving highly uniform film thickness across very large areas (e.g., >1 meter) can be challenging. It often requires complex cathode designs to ensure the plasma density is even across the entire target surface.

Is Sputtering the Right Choice for Your Application?

Choosing a deposition technique requires aligning the process capabilities with your primary goal.

- If your primary focus is high-purity films for sensitive electronics: You must account for potential gas entrapment and invest in high-purity targets and excellent vacuum systems to mitigate contamination.

- If your primary focus is high-volume manufacturing: The slow deposition rates for some materials and high energy costs must be carefully modeled to determine if the cost-per-part is acceptable.

- If your primary focus is depositing on sensitive or organic substrates: The inherent ionic bombardment and heating may make sputtering unsuitable, and alternative, "gentler" methods should be considered.

By weighing these limitations against sputtering's strengths in film adhesion and material versatility, you can make a technically sound and economically viable decision for your project.

Summary Table:

| Disadvantage Category | Key Issues |

|---|---|

| Process & Rate | Slow deposition, high substrate temperatures, limited growth control |

| Film Quality | Gas entrapment, target impurities, vacuum contamination |

| Material Constraints | Damage to sensitive substrates, challenges with lift-off patterning |

| Economic Factors | High capital investment, costly RF power supplies, uniformity challenges |

Struggling with sputtering limitations for your lab's thin film needs? KINTEK specializes in lab equipment and consumables, offering tailored solutions to overcome deposition challenges. Our experts can help you select the right equipment to ensure high-purity films, cost-effective production, and compatibility with sensitive materials. Contact us today to optimize your deposition process and achieve superior results!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Ceramic Evaporation Boat Set Alumina Crucible for Laboratory Use

People Also Ask

- What is the temperature of the CVD chamber? A Guide to High & Low-Temp Processes

- What is the CVD process of silicon carbide? Achieve Unmatched Purity for Demanding Applications

- What are the types of thin film? A Guide to PVD vs. CVD Deposition Methods

- What are the methods of deposition of thin films? A Guide to PVD, CVD, and ALD Techniques

- What are thin films used for? Enhance Durability, Optics, and Electronics

- Why is carbon coating important? Boost Battery Performance and Longevity

- What critical fundamental components are made using CVD? The Atomic-Scale Process Powering Modern Tech

- What does CVD coating stand for? Unlock Durable, High-Performance Thin Films