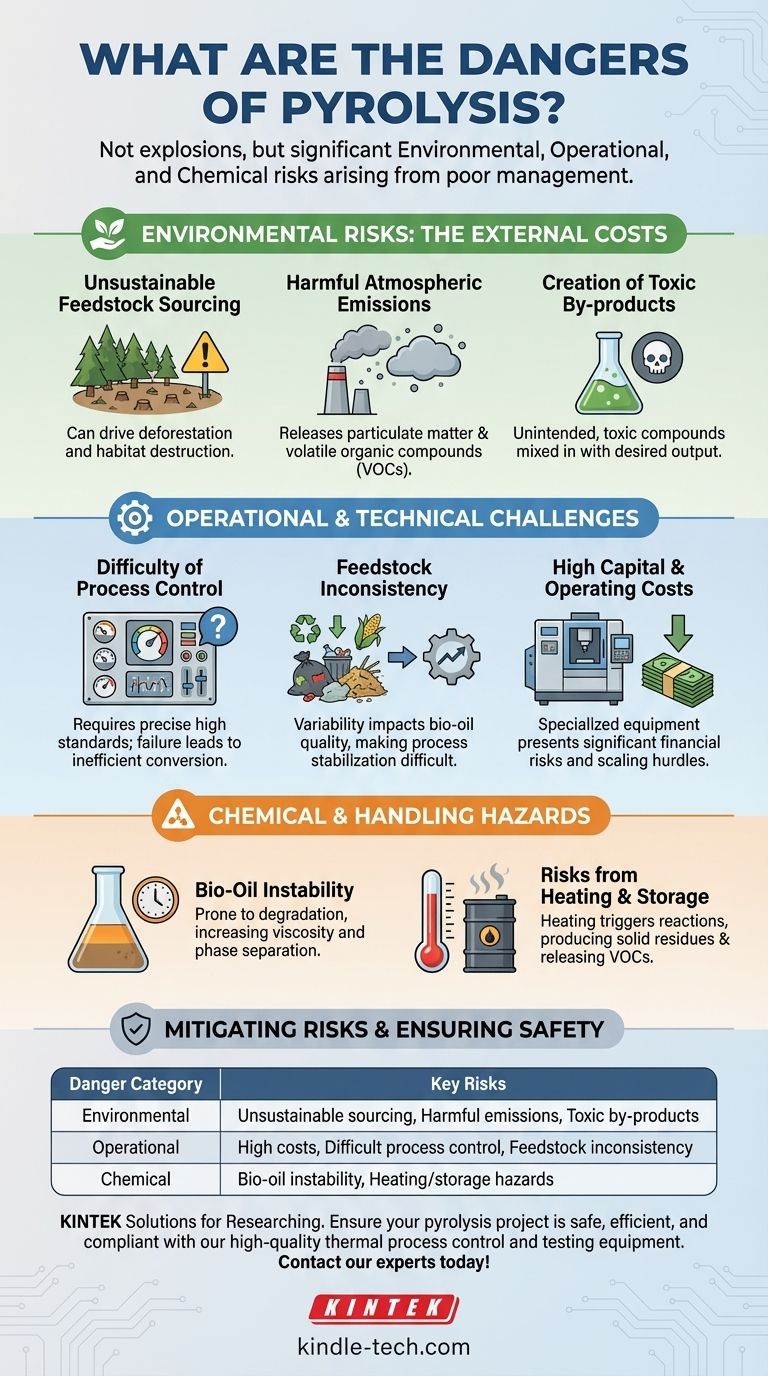

The primary dangers of pyrolysis are not explosions or immediate catastrophes but a combination of significant environmental, operational, and chemical risks. If poorly managed, the process can lead to pollution from toxic by-products and harmful emissions. Operationally, it is costly and difficult to control, while its main liquid product, bio-oil, is chemically unstable and can be hazardous to handle and store.

While pyrolysis offers a promising method for converting waste into resources, its dangers are not inherent to the core process itself. Instead, they arise from a lack of precise control over feedstock sourcing, process parameters, emissions, and final product handling.

Environmental Risks: The External Costs

The promise of turning waste into value can obscure the significant environmental footprint of a poorly executed pyrolysis operation. These risks extend from the sourcing of raw materials to the release of final emissions.

Unsustainable Feedstock Sourcing

If biomass is not sourced from sustainable waste streams, it can drive deforestation and habitat destruction. Using virgin wood or dedicated energy crops without proper land management negates the technology's "green" credentials.

Harmful Atmospheric Emissions

An improperly sealed or controlled pyrolysis system can release harmful pollutants. These include fine particulate matter and volatile organic compounds (VOCs), which contribute to air pollution and can pose health risks.

Creation of Toxic By-products

High-temperature pyrolysis, in particular, can be difficult to manage. This lack of control can result in the formation of a wide range of unintended and often toxic by-products mixed in with the desired output.

Operational and Technical Challenges

Moving from a lab-scale experiment to a commercially viable operation reveals significant technical and financial hurdles that introduce their own set of risks.

The Difficulty of Process Control

Achieving a consistent yield of high-quality products is technically demanding. The process requires very high standards for equipment and precise parameter settings. Failure to maintain control can lead to inefficient conversion and the creation of undesirable by-products.

Feedstock Inconsistency

The chemical and physical properties of feedstock, such as municipal waste or agricultural residue, can vary dramatically. This feedstock variability directly impacts the quality and composition of the final bio-oil and biochar, making process stabilization a constant challenge.

High Capital and Operating Costs

The specialized, high-temperature equipment required for pyrolysis represents a significant financial risk. The high capital and operating costs, combined with technical difficulties in scaling the process up, can make projects financially unviable.

Chemical and Handling Hazards

The products of pyrolysis, particularly bio-oil, are not inert substances. They are complex chemical mixtures that require careful management.

The Instability of Bio-Oil

Pyrolysis oil is chemically unstable because it is a mixture of reactive compounds. Over time, it is prone to degradation through condensation reactions, causing a gradual increase in viscosity and potential phase separation into unusable sludge.

Risks from Heating and Storage

The instability of bio-oil is accelerated by heat. Heating the oil to 100°C or even lower can trigger rapid reactions. This can produce a solid residue and release volatile organic compounds, creating a significant handling and storage hazard.

Mitigating Pyrolysis Risks for Your Project

The key to leveraging pyrolysis safely and effectively is to align your operational strategy with your primary objective.

- If your primary focus is environmental sustainability: Ensure your project's viability rests on verifiably sustainable feedstock and investment in robust emissions capture and control systems.

- If your primary focus is product quality and consistency: Prioritize advanced process control technology and develop strict protocols for feedstock testing and standardization before processing.

- If your primary focus is commercial viability and safety: Implement rigorous procedures for the temperature-controlled storage and handling of bio-oil, and factor product degradation into your business model.

Ultimately, managing the dangers of pyrolysis means transforming it from an uncontrolled thermal decomposition into a precise and well-engineered chemical process.

Summary Table:

| Danger Category | Key Risks |

|---|---|

| Environmental | Unsustainable feedstock sourcing, Harmful emissions (VOCs, particulate matter), Toxic by-products |

| Operational | High capital/operating costs, Difficult process control, Feedstock inconsistency |

| Chemical | Bio-oil instability (viscosity increase, phase separation), Heating/storage hazards |

Ensure your pyrolysis project is safe, efficient, and compliant. KINTEK specializes in high-quality lab equipment and consumables for precise thermal process control, emissions monitoring, and product stability testing. Our solutions help you mitigate risks and achieve consistent results—contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are the advantages of using a vacuum drying oven for iron nanoparticles? Prevent Oxidation & Sintering

- What is the function of a vacuum furnace? Achieve High-Purity, Contamination-Free Thermal Processing

- What is thermal evaporation in a vacuum pressure? A Guide to High-Purity Thin Film Deposition

- Why is vacuum important for deposition of thin films? The Key to Purity and Control in Thin Film Coating

- Why can't conduction occur in a vacuum? The Essential Role of Particles in Heat Transfer

- What is vacuum furnace high temperature? Unlock the Range for Your Material Processing

- How does thermal decomposition in furnaces influence MOCTAs? Optimize Anode Durability and Conductivity

- What is the purpose of the sintering process? Transform Powder into High-Performance Solid Parts