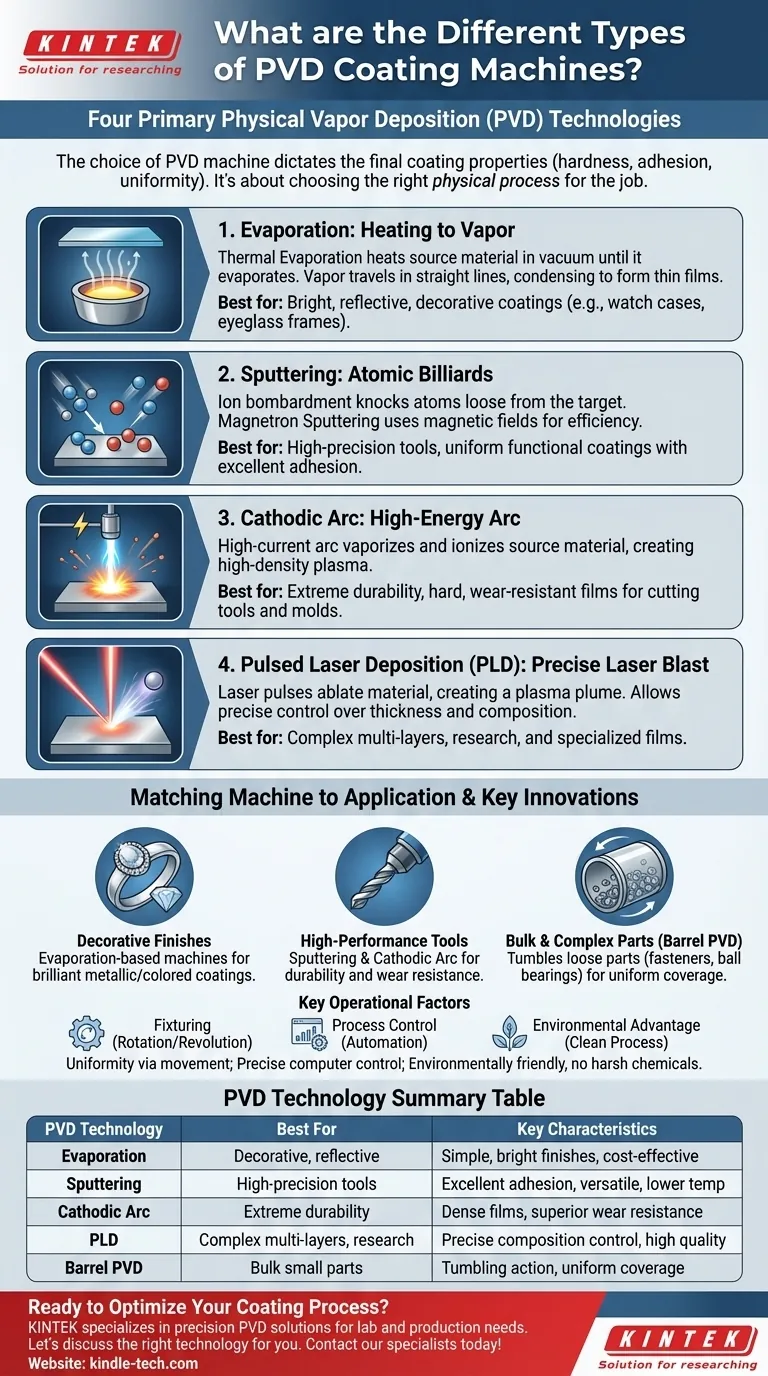

There are four primary types of Physical Vapor Deposition (PVD) coating machines, each defined by the distinct method used to vaporize the source coating material. These core technologies are Evaporation, Sputtering, Cathodic Arc, and Pulsed Laser Deposition. The choice between them is not arbitrary; it directly dictates the final properties of the coating, such as its hardness, adhesion, and uniformity.

The critical insight is that you aren't just choosing a machine; you are choosing a specific physical process. The ideal machine for your project is the one that employs the vaporization method best suited to achieve the required performance, durability, and finish for your specific components.

The Core PVD Mechanisms: How Material Becomes a Coating

To understand the machines, you must first understand the fundamental process each one uses. These methods occur in a vacuum chamber and determine the energy, density, and quality of the atoms that will form your coating.

Evaporation: Heating to Vapor

Thermal Evaporation is the most straightforward PVD method. The source coating material is heated in a high vacuum until it evaporates. These vaporized atoms then travel in a straight line until they condense onto the cooler substrate, forming a thin film.

This process is excellent for creating bright, reflective coatings and is commonly used for decorative applications where extreme wear resistance is not the primary concern.

Sputtering: Atomic Billiards

Sputtering involves a high-energy ion bombardment process. Think of it like a game of atomic billiards: high-energy ions (typically from an inert gas like argon) are shot at the source material (the "target"), knocking atoms loose.

These "sputtered" atoms are then ejected and deposit onto the substrate. Magnetron Sputtering is a common enhancement that uses magnetic fields to increase the efficiency of this process, allowing for faster deposition rates and lower temperatures.

Cathodic Arc: A High-Energy Arc

Cathodic Arc Deposition uses a high-current, low-voltage electric arc to vaporize the source material. The arc creates a tiny, intensely hot spot on the material's surface, which evaporates and ionizes a small portion of it.

This process produces a high density of ionized material, resulting in extremely dense, hard, and well-adhered coatings. It is a powerful method for creating high-performance functional films.

Pulsed Laser Deposition (PLD): A Precise Laser Blast

Pulsed Laser Deposition (PLD) is a more specialized technique. It uses a high-power laser focused on the target material inside the vacuum chamber. Each laser pulse ablates, or blasts away, a tiny amount of the material, creating a plasma plume that then deposits onto the substrate.

This method offers precise control over film thickness and composition, making it valuable for research and the creation of complex, multi-layered films.

Matching the Machine to the Application

The right PVD machine is determined by the end-use of the coated part. Each technology excels in different areas.

For Decorative Finishes

Evaporation-based machines are the go-to choice for decorative applications. They are used to coat items like watch cases, eyeglass frames, mobile phone bodies, and hardware. The process excels at producing brilliant metallic and colored finishes.

For High-Performance and Precision Tools

Sputtering and Cathodic Arc machines are ideal for functional coatings where durability is paramount. They create the hard, wear-resistant films needed on cutting tools, industrial molds, and complex carbide components, extending their operational life significantly.

For Bulk Parts and Complex Geometries

A recent innovation is the Barrel PVD coating machine. This specialized equipment is designed to handle large volumes of small, loose components like fasteners, powders, or ball bearings by tumbling them gently in a rotating drum during the coating cycle, ensuring uniform coverage.

Understanding the Key Operational Factors

Beyond the core technology, practical operational features distinguish modern PVD machines.

The Importance of Fixturing

To ensure a uniform coating on all surfaces, parts must be moved within the vacuum chamber. Fixtures in PVD machines can operate via rotation, revolution (orbiting a central axis), or a combination of both to expose every angle of the component to the vapor source.

Process Control and Efficiency

Modern PVD machines are computer-controlled, enabling precise management of the coating process and allowing operators to multitask. This automation reduces production costs and turnaround times, making PVD suitable for both high-volume manufacturing and small, custom batches.

The Environmental Advantage

A significant benefit of all PVD processes is that they are environmentally friendly. As a purely physical method, PVD avoids the use of the harsh and toxic chemicals associated with traditional electroplating, resulting in a cleaner and safer operation.

How to Select the Right PVD Process

Your final choice should be guided entirely by your goal for the finished product.

- If your primary focus is aesthetics and cost-effective finishes: Evaporation-based machines provide brilliant decorative coatings for consumer goods.

- If your primary focus is durability, wear resistance, and precision: Sputtering or Cathodic Arc machines will deliver the dense, hard coatings required for tools and industrial parts.

- If your primary focus is coating large volumes of small, loose parts: A specialized Barrel PVD coater is the most efficient and effective solution.

Choosing the right machine begins with a clear understanding of your coating's required performance, as the deposition method dictates the final result.

Summary Table:

| PVD Technology | Best For | Key Characteristics |

|---|---|---|

| Evaporation | Decorative finishes, reflective coatings | Simple process, bright metallic finishes, cost-effective |

| Sputtering | High-precision tools, uniform coatings | Excellent adhesion, lower temperature process, versatile |

| Cathodic Arc | Extreme durability, hard coatings | Dense films, superior wear resistance, high ionization |

| Pulsed Laser Deposition | Complex multi-layers, research applications | Precise composition control, high-quality films |

| Barrel PVD | Bulk small parts, complex geometries | Tumbling action, uniform coverage on loose components |

Ready to Optimize Your Coating Process?

KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision PVD coating solutions. Whether you're developing decorative finishes, high-performance tools, or specialized components, our expertise ensures you get the right technology for your specific requirements.

We provide:

- Tailored PVD equipment recommendations based on your application

- Expert guidance on process optimization and fixturing

- Environmentally friendly coating solutions that outperform traditional methods

- Support for both research and production-scale operations

Let's discuss how the right PVD technology can enhance your product's performance and durability. Contact our coating specialists today for a personalized consultation and discover how KINTEK can advance your coating capabilities.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Touchscreen Automatic Vacuum Heat Press

- Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

People Also Ask

- How many types of sputtering are there? A Guide to DC, RF, and Advanced Techniques

- What is the RF frequency for sputtering? Unlocking the Standard for Insulating Materials

- What is a sputtering system? Achieve Unmatched Thin Film Deposition for Your Lab

- What are the effects of magnetron sputtering? Achieve High-Quality, Durable Thin Films for Your Lab

- How many types of vapor phase deposition techniques are present? PVD vs. CVD Explained