At its core, a pyrolysis furnace is distinguished primarily by its mechanical design, which dictates how it heats the feedstock. The two most common types are rotary kiln reactors and fluidized bed reactors, each optimized for different processes and end products. While other designs like screw or microwave reactors exist for specialized applications, the vast majority of industrial pyrolysis operations rely on one of these two workhorse technologies.

The choice of a pyrolysis furnace is not about the hardware itself, but about the desired outcome. The furnace design is a direct consequence of the process you need to run—fast pyrolysis for bio-oil or slow pyrolysis for biochar—and selecting the right one is critical to achieving your target product yield.

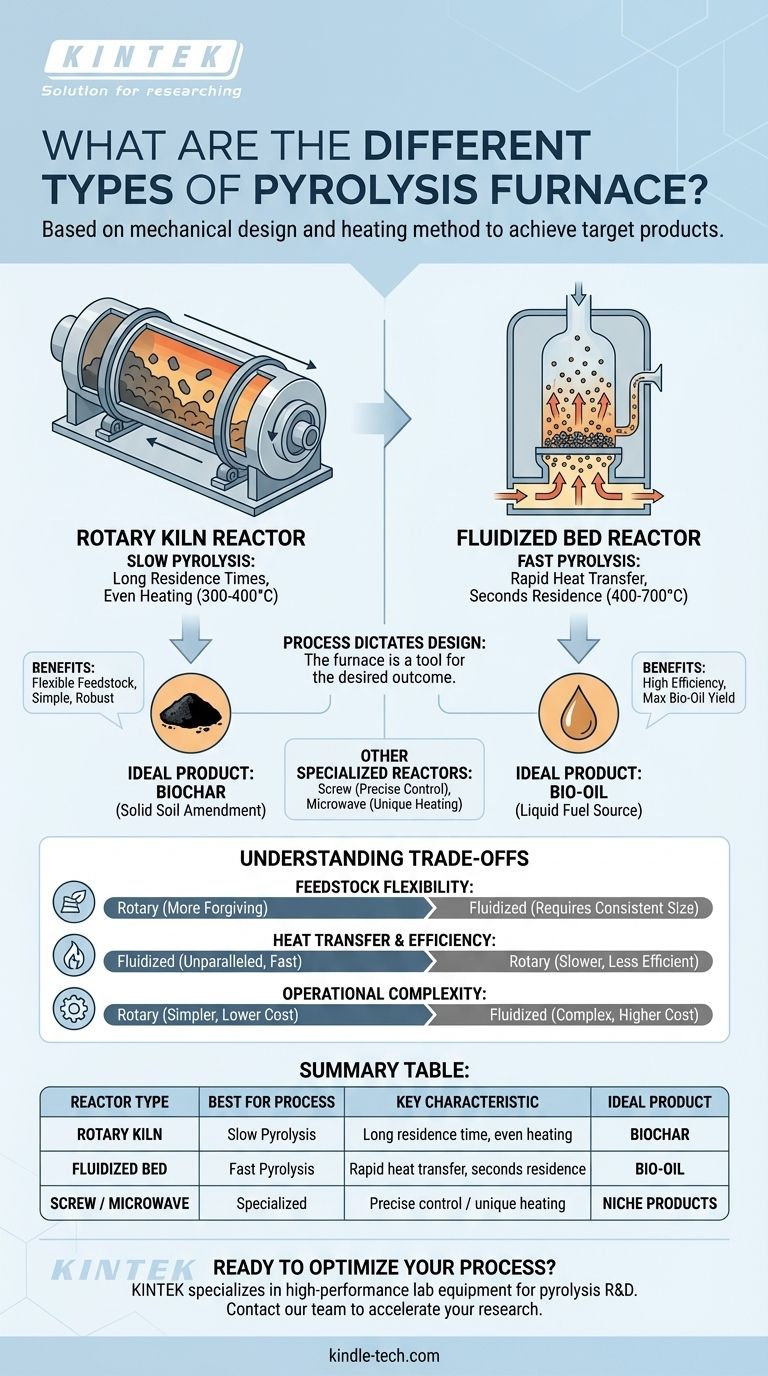

The Two Core Furnace Designs

The physical structure of a pyrolysis reactor determines its heat transfer characteristics and how long it can hold material, which are the most critical variables in the process.

Rotary Kiln Reactors

A rotary kiln is a large, rotating cylindrical vessel. Feedstock is fed into one end, and as the drum slowly rotates, the material tumbles and moves down its length, ensuring it is heated evenly.

This design is mechanically simple and robust. The slower, controlled movement makes rotary kilns particularly well-suited for processes requiring longer residence times.

Fluidized Bed Reactors

In a fluidized bed reactor, a stream of hot gas is forced up through a bed of solid particles, such as sand. This causes the solids to circulate and behave like a fluid.

When feedstock is introduced into this "fluidized" bed, it is immediately surrounded by the hot particles, resulting in extremely rapid and efficient heat transfer. This makes it ideal for processes that must happen in seconds.

Other Specialized Reactors

While less common, other designs serve specific niches. Screw reactors use an auger to move material through a heated tube, offering precise control over residence time. Microwave reactors use microwave energy for heating, which can offer unique reaction pathways but is often more complex and costly to scale.

Process Dictates Design: Fast vs. Slow Pyrolysis

The reason different furnace designs exist is that they are optimized for different chemical processes. The goal—whether it's producing a liquid fuel or a solid soil amendment—determines which furnace is the correct tool for the job.

Fast Pyrolysis for Bio-Oil

The goal of fast pyrolysis is to maximize the production of liquid bio-oil. This requires heating the biomass to high temperatures (400-700°C) very quickly, in a matter of seconds, to "crack" the organic matter into vapor before it can form solid char.

This is why fluidized bed reactors are the standard for fast pyrolysis. Their exceptional heat transfer capability ensures the biomass is heated almost instantly, optimizing the conditions for bio-oil yield (often around 60%).

Slow Pyrolysis for Biochar

Conversely, the goal of slow pyrolysis is to maximize the production of solid biochar. This process uses lower temperatures (300-400°C) and much longer heating times, often spanning several hours.

This slow "cooking" process is designed to drive off volatile compounds while preserving the carbon structure. Rotary kiln reactors are an excellent fit for this, as their design naturally accommodates long residence times and provides the consistent, gentle heating needed to create high-quality char.

Understanding the Trade-offs

No single design is universally superior; each comes with inherent advantages and disadvantages that make it suitable for different applications.

Feedstock Flexibility

Rotary kilns are generally more forgiving of non-uniform feedstock, handling larger and more varied particle sizes without issue. Fluidized beds, however, typically require feedstock to be milled to a consistent, fine particle size to ensure proper fluidization.

Heat Transfer and Efficiency

Fluidized bed reactors offer unparalleled heat transfer rates, making them highly efficient for the rapid reactions of fast pyrolysis. The indirect heating in a rotary kiln is inherently slower and less thermally efficient, though simpler to operate.

Operational Complexity

The simplicity of a rotary kiln often translates to lower capital costs and easier operation. Fluidized bed systems are more complex, requiring sophisticated gas handling systems and precise process control to maintain the fluidized state, which can increase both initial and operational costs.

Making the Right Choice for Your Goal

Selecting the correct pyrolysis technology begins with defining your primary product.

- If your primary focus is maximizing bio-oil production: A fluidized bed reactor designed for fast pyrolysis is the standard industry choice due to its superior heat transfer.

- If your primary focus is maximizing high-quality biochar: A rotary kiln reactor is often preferred, as its design is well-suited for the long residence times and even heating of slow pyrolysis.

- If you are handling highly variable or bulky feedstock: The robust and simple design of a rotary kiln may offer more operational flexibility than a more sensitive fluidized bed reactor.

Ultimately, understanding the direct link between your target product and the reactor's operating principle is the key to a successful pyrolysis project.

Summary Table:

| Reactor Type | Best For Process | Key Characteristic | Ideal Product |

|---|---|---|---|

| Rotary Kiln | Slow Pyrolysis | Long residence time, even heating | Biochar |

| Fluidized Bed | Fast Pyrolysis | Rapid heat transfer, seconds residence | Bio-Oil |

| Screw / Microwave | Specialized Applications | Precise control / unique heating | Niche Products |

Ready to select the right pyrolysis furnace for your specific bio-oil or biochar production goals?

KINTEK specializes in high-performance lab equipment and consumables for pyrolysis research and development. Our experts can help you choose the right reactor technology to optimize your process efficiency and target product yield.

Contact our team today to discuss your project requirements and discover how KINTEK's solutions can accelerate your bioenergy or biochar research.

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity

- What is the function of a high-temperature furnace during burnout? Master Aluminum Foam Production with Precision

- How are tube furnaces classified based on the orientation of the tube? Choose the Right Design for Your Process

- What is a rotary retort furnace? Achieve Superior Uniformity in Continuous Heat Treatment

- How do tube furnaces or muffle furnaces ensure stoichiometric accuracy during synthesis? Mastering Li4GeO4 & Li4VO4