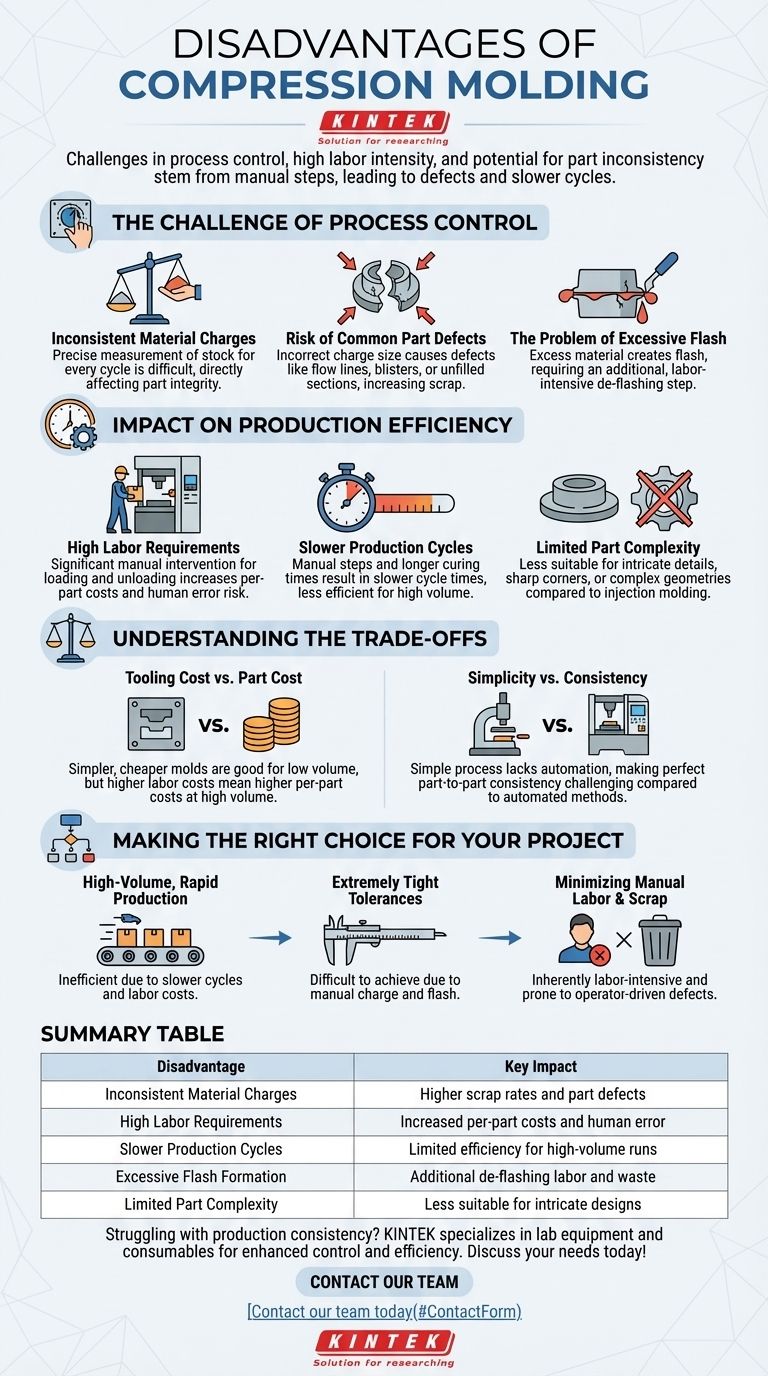

The primary disadvantages of compression molding are its challenges with process control, higher labor intensity, and the potential for part inconsistency. These factors stem from the manual steps required to load the material charge and unload the finished parts, which can lead to defects and slower production cycles compared to more automated methods.

While often chosen for its lower initial tooling costs, compression molding's core disadvantages lie in its manual nature. This introduces variability that can impact part quality, increase labor costs, and limit production speed, making it less suitable for high-volume or high-precision applications.

The Challenge of Process Control

The quality of a compression-molded part is highly dependent on the precision of the initial setup. Unlike automated processes, this relies heavily on operator skill and consistency.

Inconsistent Material Charges

Success begins with the "charge"—the pre-measured amount of molding material placed into the mold cavity. Accurately cutting or weighing this stock for every single cycle is a significant challenge.

This step is critical because the charge volume directly dictates the final part's integrity.

Risk of Common Part Defects

If the material charge is too small or placed incorrectly, it can result in significant defects. These include flow lines, surface blisters, or sections of the part that are completely unfilled.

Such defects often lead to a higher scrap rate, increasing material waste and overall production cost.

The Problem of Excessive Flash

Conversely, using too much material creates its own problems. The excess rubber or plastic is squeezed out between the two halves of the mold, forming a thin, unwanted flange known as flash.

Heavy flash is often difficult to remove cleanly and adds an extra, labor-intensive de-flashing step to the production process.

The Impact on Production Efficiency

The manual aspects of compression molding directly influence its speed and cost-effectiveness, especially as production volume increases.

High Labor Requirements

The process requires significant manual intervention. An operator must load the material charge for every cycle and manually remove the finished part after curing.

This dependence on manual labor makes per-part costs higher than in automated processes and introduces potential for human error.

Slower Production Cycles

The combination of manual loading, unloading, and often longer curing times under heat and pressure results in slower cycle times.

This makes compression molding less efficient for high-volume production runs where speed is a critical factor.

Limitations in Part Complexity

While excellent for many designs, compression molding is generally less suited for producing parts with highly intricate details, sharp corners, or complex geometries.

Processes like injection molding offer greater design freedom for creating more complex and precise components.

Understanding the Trade-offs

Choosing compression molding involves a clear trade-off between tooling investment and per-part production costs.

Tooling Cost vs. Part Cost

Compression molds are typically simpler and less expensive to manufacture than complex injection molds. This makes the process attractive for prototyping and low-to-medium volume production.

However, the higher labor requirements and slower cycles mean the cost per part can be greater, especially at higher volumes.

Simplicity vs. Consistency

The inherent simplicity of the process is one of its strengths. Yet, this same simplicity is tied to a lack of automation, which creates challenges in achieving perfect part-to-part consistency.

Automated processes offer tighter control over variables, leading to a more repeatable and predictable output.

Making the Right Choice for Your Project

Evaluating these disadvantages against your project's specific goals is the key to selecting the right manufacturing method.

- If your primary focus is high-volume, rapid production: Compression molding's slower cycle times and high labor costs make it an inefficient choice.

- If your primary focus is achieving extremely tight tolerances: The manual charge process and potential for flash can make consistent, high-precision results difficult.

- If your primary focus is minimizing manual labor and scrap rates: The process is inherently labor-intensive and more prone to operator-driven defects.

Ultimately, understanding these limitations is essential for leveraging compression molding for the applications where it truly excels.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Inconsistent Material Charges | Higher scrap rates and part defects |

| High Labor Requirements | Increased per-part costs and human error |

| Slower Production Cycles | Limited efficiency for high-volume runs |

| Excessive Flash Formation | Additional de-flashing labor and waste |

| Limited Part Complexity | Less suitable for intricate designs |

Struggling with production consistency? KINTEK specializes in lab equipment and consumables, providing solutions that enhance process control and efficiency. Whether you're refining your compression molding process or exploring alternatives, our expertise can help you achieve higher quality and lower costs. Contact our team today to discuss your specific laboratory needs!

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- Small Injection Molding Machine for Lab Use

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Automatic Laboratory Heat Press Machine

People Also Ask

- How do laboratory hydraulic presses and molds ensure accuracy in high-strength gypsum concrete testing?

- What are the examples where hydraulic press is applicable? From Sample Prep to Industrial Manufacturing

- What is the primary purpose of a laboratory hydraulic press for EIS testing on RPPO? Ensure Reliable Data Accuracy

- What are maintenance requirements for the hydraulic systems? Proactive Strategies for Maximum Uptime

- What is the effect of particle size on XRF measurements? Achieve Accurate & Reliable Results

- What causes hydraulics to run slow? Diagnose Flow Issues for Faster Operation

- What are the risks of a hydraulic press machine? Managing High-Pressure Hazards for Safer Operation

- Why is a laboratory hydraulic press used to pelletize inorganic solid electrolytes? Enhance Ionic Conductivity Testing