While powerful and versatile, the primary disadvantages of electron beam evaporation are its high equipment cost, operational complexity, and the tendency to produce porous, less-dense thin films. The process also presents significant high-voltage safety hazards and is poorly suited for uniformly coating complex, three-dimensional surfaces due to its line-of-sight nature.

Electron beam evaporation offers exceptional deposition speed and material versatility, but this performance comes at a cost. The core trade-off lies in accepting higher system complexity, significant capital investment, and potential film quality issues in exchange for its high-energy capabilities.

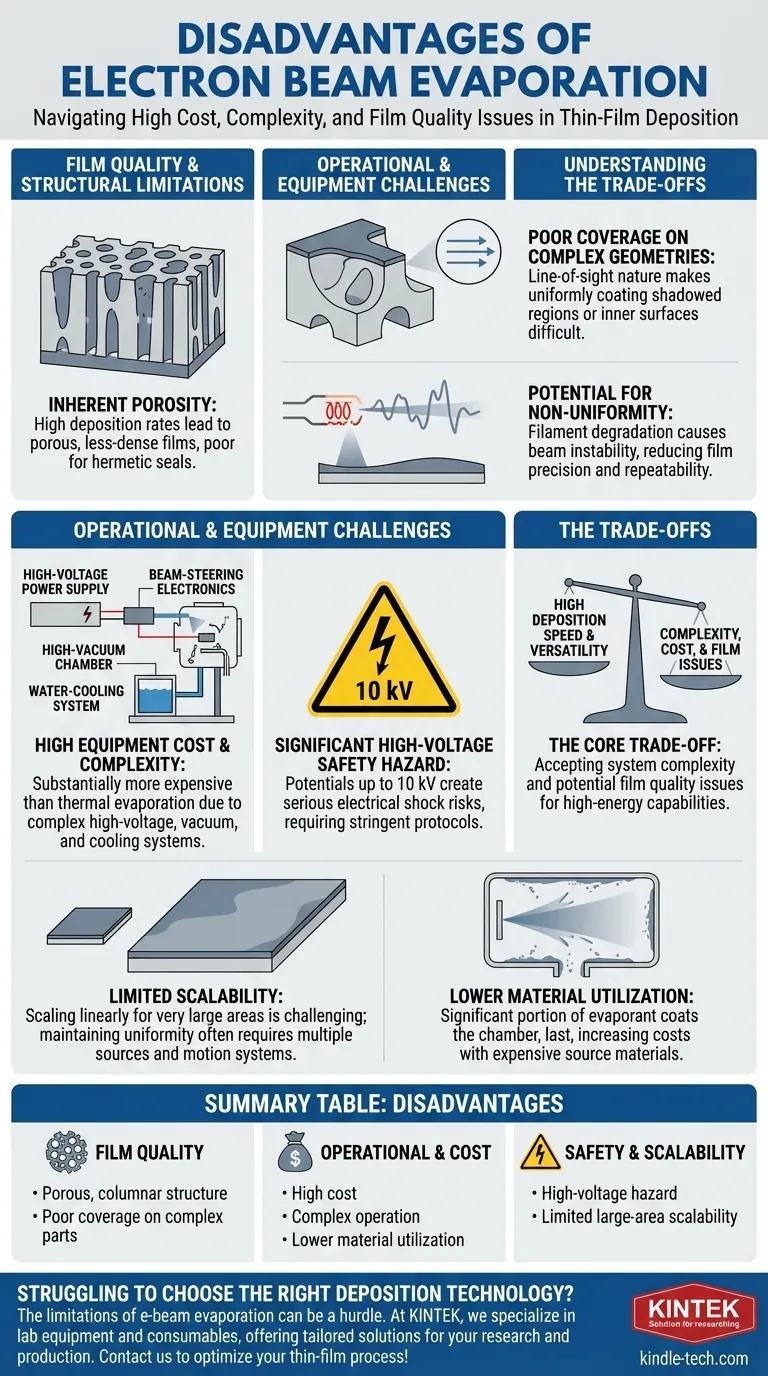

Film Quality and Structural Limitations

The high-energy, directional nature of e-beam evaporation directly impacts the final structure and quality of the deposited thin film.

Inherent Porosity of Deposited Layers

The very high deposition rates achievable with e-beam evaporation can be a drawback. Atoms arrive at the substrate with high energy but may not have sufficient time or mobility to settle into their lowest energy state, resulting in a film with a porous, columnar structure.

This porosity is a significant limitation for applications requiring hermetic seals or protection from corrosive climatic environments.

Poor Coverage on Complex Geometries

Electron beam evaporation is a line-of-sight deposition technique. The vaporized material travels in a straight line from the source to the substrate.

This makes it fundamentally unsuitable for uniformly coating the inner surfaces or shadowed regions of complex, non-planar objects.

Potential for Non-Uniformity

The electron-emitting filament within the system degrades over time. This degradation can lead to fluctuations and instability in the electron beam's intensity or position.

Such instability can cause a non-uniform evaporation rate from the source material, reducing the precision and repeatability of the film's thickness across the substrate.

Operational and Equipment Challenges

Beyond the physics of deposition, the practical implementation of an e-beam system introduces several hurdles related to cost, complexity, and safety.

High Equipment Cost and Complexity

Compared to simpler methods like thermal evaporation (using a filament or boat), e-beam systems are substantially more expensive.

This cost is driven by the need for a high-voltage power supply, complex beam-steering electronics, a high-vacuum chamber, and a water-cooling system to manage the intense heat generated at the source.

Significant High-Voltage Safety Hazard

The process relies on accelerating electrons through an electric field with a potential difference that can be as high as 10 kV.

This creates a serious high-voltage safety risk, requiring stringent safety protocols and well-trained operators to prevent electrical shock.

Understanding the Trade-offs

Choosing e-beam evaporation requires a clear understanding of its inherent compromises, especially concerning scalability and efficiency.

Limited Scalability

While excellent for specific applications like ophthalmic coatings, linearly scaling the e-beam process for very large area deposition can be challenging.

Maintaining uniform deposition rates and film properties over large substrates often requires complex substrate motion or multiple sources, increasing system complexity and cost.

Lower Material Utilization

The deposition plume from the source is not perfectly directional, leading to a significant portion of the evaporant material coating the inside of the vacuum chamber instead of the substrate.

This can result in lower material utilization compared to other techniques like sputtering, which becomes a major cost factor when using expensive source materials.

Making the Right Choice for Your Goal

Ultimately, the "disadvantages" of e-beam evaporation are only disadvantages if they conflict with your specific project goals.

- If your primary focus is high deposition speed for refractory metals or ceramics: E-beam is a leading choice, but budget for the high initial cost and consider an ion-assist source to improve film density.

- If your primary focus is coating complex, non-planar surfaces: Avoid e-beam and investigate conformal methods like Atomic Layer Deposition (ALD) or Chemical Vapor Deposition (CVD).

- If your primary focus is minimizing cost for simple metal films: A basic thermal evaporation system offers a much lower barrier to entry in terms of both cost and complexity.

- If your primary focus is achieving the highest possible film density and adhesion: Magnetron sputtering is often a superior alternative, though typically with lower deposition rates.

Matching your application's requirements to the specific profile of a deposition technology is the key to a successful outcome.

Summary Table:

| Disadvantage Category | Key Drawbacks |

|---|---|

| Film Quality | Porous, columnar film structure; Poor coverage on complex geometries |

| Operational & Cost | High equipment cost; Complex operation; Lower material utilization |

| Safety & Scalability | Significant high-voltage hazard; Limited scalability for large areas |

Struggling to choose the right thin-film deposition technology for your lab? The limitations of electron beam evaporation—like high cost and poor conformity—can be a major hurdle. At KINTEK, we specialize in lab equipment and consumables, offering tailored solutions to meet your specific research and production goals. Whether you need guidance on alternative methods like sputtering or ALD, or a system that balances performance with budget, our experts are here to help. Contact us today to optimize your thin-film process and achieve superior results!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What is the process of evaporation heating? Master the Balance of Heat, Vacuum, and Surface Area

- What is the process of electron beam deposition? Achieve High-Purity, Cost-Effective Thin Films

- What are the advantages of using Monel alloy reactors and nickel sample boats? Secure Purity in Carbon Fluorination

- What is the process of vacuum deposition? Achieve Atomic-Level Precision Coatings

- How does e-beam evaporation work? A Guide to High-Purity Thin Film Deposition

- Is electron beam assisted evaporation used for metals? The Key to High-Purity, High-Melting-Point Metal Films

- What metals can be deposited by vacuum deposition? Achieve Precise Surface Properties for Your Application

- How is physical vapor deposition performed using an electron beam evaporator? A Guide to High-Purity Thin Films