While a powerful technique, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is not without significant disadvantages. Its primary drawbacks stem from the very chemicals it uses, which introduce safety hazards and can compromise film purity. Furthermore, the use of plasma, while enabling lower temperatures, can itself introduce defects and stresses into the deposited film.

PECVD was developed to solve the high-temperature problem of conventional CVD, but this solution comes at a cost. The core trade-off is accepting potential compromises in film quality and significant chemical safety risks in exchange for a much lower thermal budget.

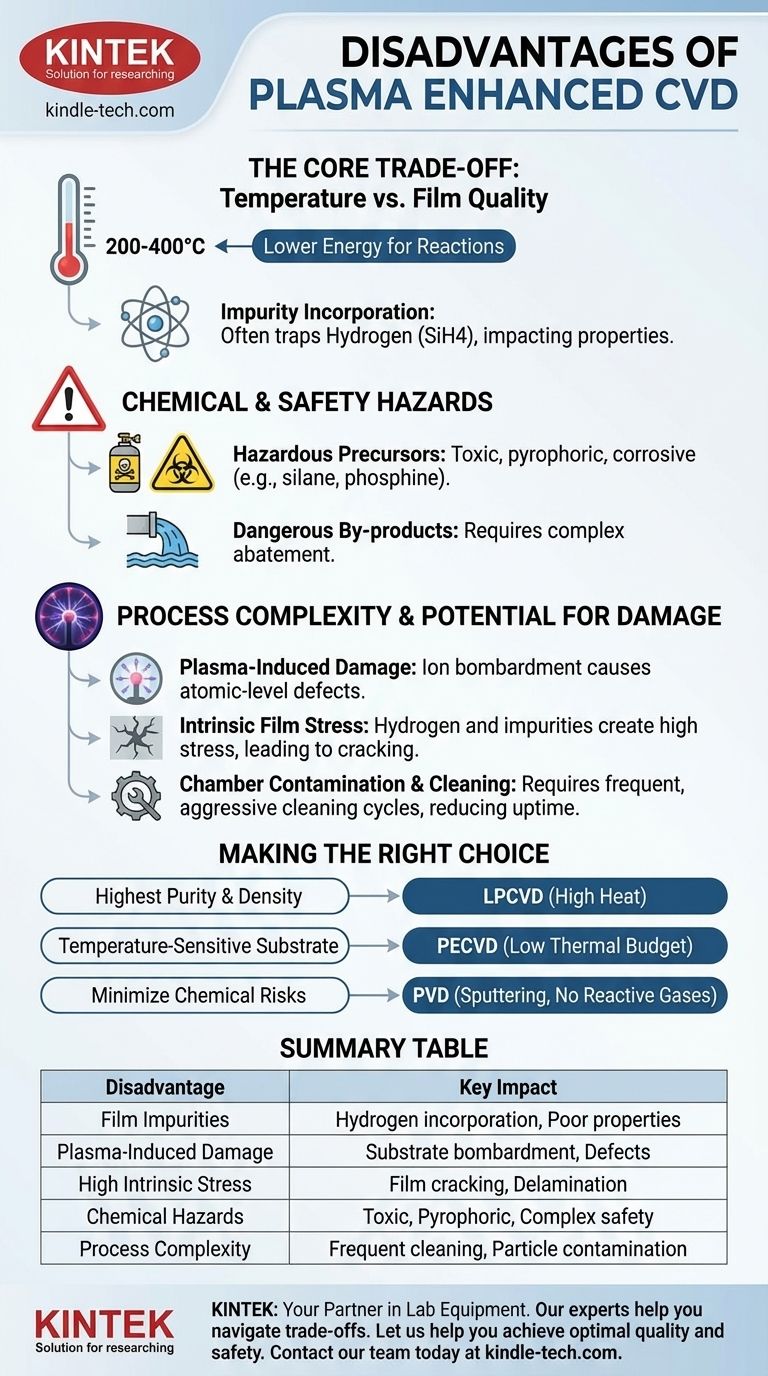

The Trade-off: Temperature vs. Film Quality

The central value of PECVD is its ability to operate at lower temperatures (typically 200-400°C) than conventional CVD methods, which can require 600-1000°C or more.

Lower Energy for Reactions

At lower temperatures, the chemical precursors have less thermal energy to react and form a high-quality film on the substrate surface.

The plasma provides the missing energy, but this activation method is less "clean" than pure thermal energy, which can impact the final material properties.

Impurity Incorporation

Because the chemical reactions are not driven to completion by high heat, PECVD films often contain significant impurities.

A common example is the incorporation of hydrogen from precursor gases like silane (SiH4). This trapped hydrogen can negatively affect the film's electrical properties, density, and long-term stability.

Chemical and Safety Hazards

Like all CVD processes, PECVD relies on volatile and often dangerous chemical precursors.

Use of Hazardous Precursors

Many source gases used in PECVD are toxic, pyrophoric (ignite spontaneously in air), or corrosive.

Materials like silane and phosphine are extremely hazardous and require specialized, expensive handling, storage, and gas delivery systems.

Dangerous By-products

The chemical reactions create waste by-products that must be safely managed. These effluent streams often contain unreacted toxic gases and other hazardous compounds that require abatement systems before they can be released.

Process Complexity and Potential for Damage

The "plasma-enhanced" aspect of PECVD introduces unique challenges that are not present in purely thermal CVD or physical deposition methods.

Plasma-Induced Damage

The high-energy ions within the plasma can physically bombard the substrate surface as the film is being deposited.

This bombardment can create atomic-level defects in the film or the underlying substrate, which is a major concern for sensitive electronic devices where such damage can degrade performance.

Intrinsic Film Stress

While PECVD avoids the high thermal stress associated with high-temperature CVD, the incorporation of impurities (like hydrogen) and the effects of ion bombardment create high intrinsic stress in the film. This stress must be carefully managed to prevent cracking or delamination.

Chamber Contamination and Cleaning

The plasma environment promotes deposition on all surfaces inside the chamber, not just the target wafer.

This requires frequent and aggressive in-situ plasma cleaning cycles to remove the unwanted material. These cleaning cycles reduce equipment uptime and can be a source of particles that contaminate subsequent production wafers.

Making the Right Choice for Your Application

Understanding these disadvantages is key to selecting the appropriate deposition technology for your specific goal.

- If your primary focus is the absolute highest film purity and density: A high-temperature process like Low-Pressure CVD (LPCVD) may be a better choice, provided your substrate can tolerate the heat.

- If your primary focus is deposition on a temperature-sensitive substrate: PECVD is often the necessary and optimal choice, as its low thermal budget protects underlying materials like polymers or existing metal layers.

- If your primary focus is minimizing chemical and safety risks: A Physical Vapor Deposition (PVD) method like sputtering should be considered, as it avoids the use of highly reactive and toxic precursor gases.

Ultimately, choosing a deposition method requires a clear understanding of the trade-offs between processing conditions, safety, cost, and the desired final film properties.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Film Impurities | Hydrogen incorporation, poor electrical properties, low density |

| Plasma-Induced Damage | Substrate bombardment, atomic-level defects |

| High Intrinsic Stress | Risk of film cracking or delamination |

| Chemical Hazards | Toxic, pyrophoric gases (e.g., silane) requiring complex safety systems |

| Process Complexity | Frequent chamber cleaning, particle contamination, reduced uptime |

Choosing the right deposition technology is critical to your project's success. The disadvantages of PECVD—like film impurities and safety risks—must be balanced against its low-temperature advantages.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you navigate these trade-offs and select the ideal equipment for your specific application, whether it's PECVD, LPCVD, or PVD.

Let us help you achieve optimal film quality and process safety. Contact our team today for a personalized consultation to enhance your lab's capabilities and efficiency.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the advantages of DLC coating? Achieve Superior Hardness, Low Friction & Corrosion Resistance

- What is plasma in PECVD? The Key to Low-Temperature, High-Quality Thin-Film Deposition

- Why do PECVD systems operate at low pressure and low temperature? Protect Sensitive Substrates with Plasma Energy

- What temperature does plasma deposition occur? Master Low-Temp Film Deposition for Sensitive Materials

- How is PECVD different from CVD? Unlock Low-Temperature Thin Film Deposition

- What role does a gas mass flow control system play in DLC deposition? Mastering Chemical Uniformity and Silver Doping

- How does the PECVD process utilize plasma to deposit thin films? Achieve High-Quality Coatings at Low Temperatures

- How much does DLC coating cost? A Detailed Breakdown of Pricing Factors