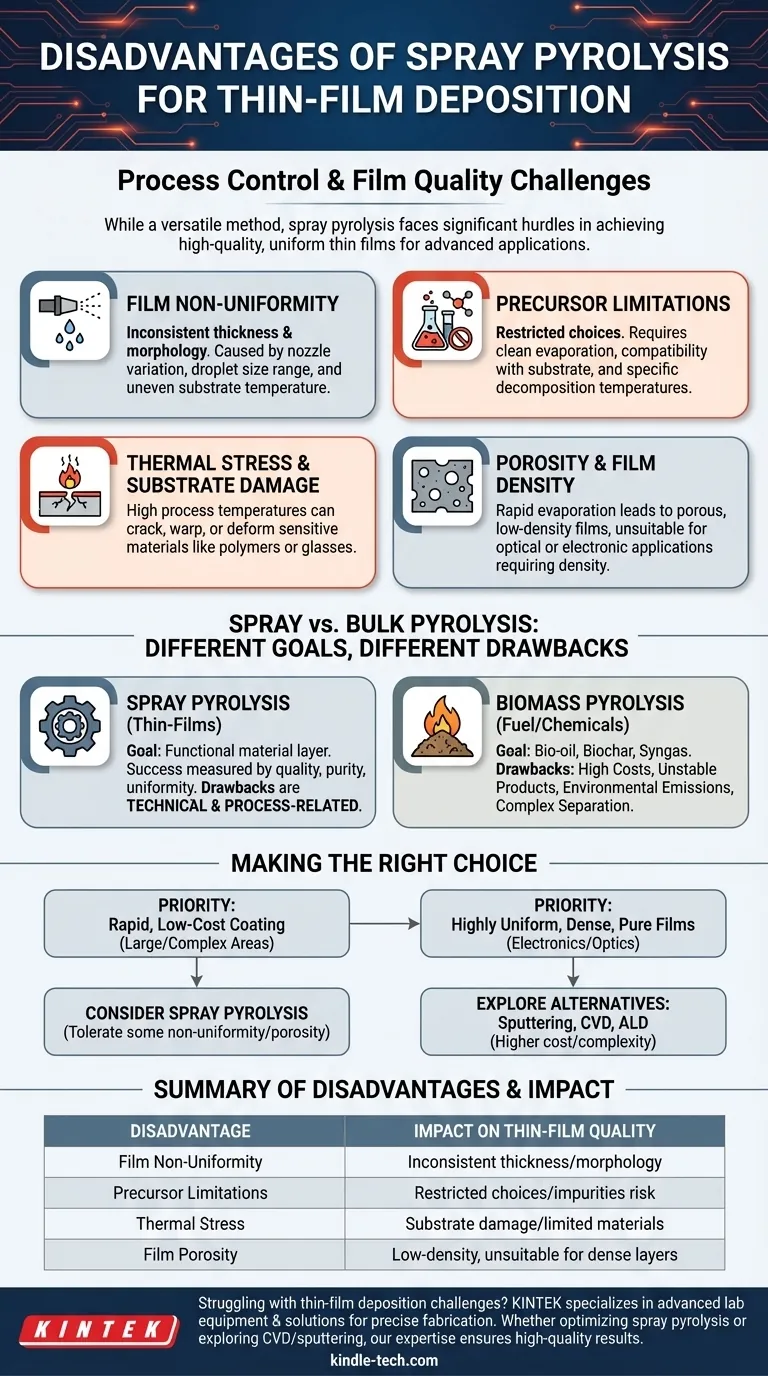

While a versatile method for thin-film deposition, the primary disadvantages of spray pyrolysis relate to process control and the resulting film quality. Key challenges include achieving uniform film thickness, managing thermal stress on the substrate, and dealing with limitations in the chemical precursors that can be used effectively.

The core challenge of spray pyrolysis is not the cost or by-products associated with large-scale fuel production, but the difficulty in precisely controlling the deposition process to create high-quality, dense, and uniform thin films for advanced applications.

Key Disadvantages of Spray Pyrolysis

Spray pyrolysis is a technique where a precursor solution is atomized and sprayed onto a heated surface (substrate). The droplets undergo evaporation and thermal decomposition, leaving behind a solid thin film. While simple and scalable, the process has several intrinsic drawbacks.

### Difficulty in Achieving Film Uniformity

The most significant challenge is producing films with consistent thickness and morphology across the entire substrate.

Several factors contribute to this, including non-uniform spray density from the nozzle, variations in droplet size, and uneven temperature distribution across the substrate surface. This can result in films that are thicker in some areas and thinner in others, compromising device performance.

### Limitations in Precursor Selection

The choice of chemical precursors is restricted. The metal salts or organometallic compounds used must be soluble in a solvent that evaporates cleanly without leaving residue.

Furthermore, the precursor must decompose at a temperature that is compatible with the substrate material and results in the desired final compound without forming unwanted secondary phases or impurities.

### Thermal Stress and Substrate Damage

Spray pyrolysis requires heating the substrate to high temperatures, often several hundred degrees Celsius, to facilitate the chemical reaction.

This high temperature can induce thermal stress, causing sensitive substrates like certain polymers or glasses to crack, warp, or deform. It also limits the application of this technique for materials that are not thermally stable.

### Porosity and Film Density

The rapid evaporation of the solvent and decomposition of the precursor can lead to the formation of porous, low-density films.

While porosity can be beneficial for applications like sensors or catalysts, it is a significant disadvantage for optical or electronic applications where a dense, pinhole-free film is essential for optimal performance.

Understanding the Trade-offs: Spray vs. Bulk Pyrolysis

It is critical to distinguish spray pyrolysis from the large-scale biomass pyrolysis mentioned in many general discussions. The goals, and therefore the disadvantages, are fundamentally different.

### The Goal of Spray Pyrolysis: Thin-Film Deposition

The purpose of spray pyrolysis is to manufacture a functional material layer on a surface. Success is measured by film quality, purity, and uniformity. Its disadvantages, as listed above, are technical and process-related.

### The Goal of Biomass Pyrolysis: Fuel and Chemical Production

The purpose of biomass pyrolysis is to thermally decompose organic matter (like wood or waste) in the absence of oxygen to produce bio-oil, biochar, and syngas.

### Disadvantages Specific to Biomass Pyrolysis

The drawbacks commonly cited for general "pyrolysis" apply almost exclusively to this large-scale industrial process. These include:

- High Capital and Energy Costs: The process requires large, expensive reactors and significant energy input to maintain high temperatures.

- Unstable End-Products: The resulting bio-oil is often acidic, viscous, and chemically unstable, requiring costly refining before it can be used as a transportation fuel.

- Environmental Emissions: Without proper furnace design and control, the high-temperature process can produce harmful emissions that negatively impact air quality.

- Product Separation: The output is a mix of liquid, solid, and gas, which requires an efficient and sometimes expensive separation and purification process.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on your project's priorities regarding cost, scale, and final film quality.

- If your primary focus is rapid, low-cost coating of large or complex-shaped areas: Spray pyrolysis is a strong contender, provided you can tolerate some variation in film uniformity and porosity.

- If your primary focus is creating highly uniform, dense, and pure films for high-performance electronics or optics: Alternative methods like sputtering, chemical vapor deposition (CVD), or atomic layer deposition (ALD) will likely provide superior results despite their higher cost and complexity.

Ultimately, understanding these process-specific limitations is the first step toward optimizing spray pyrolysis for your application or choosing a more suitable alternative.

Summary Table:

| Disadvantage | Impact on Thin-Film Quality |

|---|---|

| Film Non-Uniformity | Inconsistent thickness and morphology across the substrate |

| Precursor Limitations | Restricted choice of chemicals, risk of impurities |

| Thermal Stress | Substrate damage, limits use on heat-sensitive materials |

| Film Porosity | Results in low-density films, unsuitable for dense layer needs |

Struggling with thin-film deposition challenges? KINTEK specializes in lab equipment and consumables, providing advanced solutions for precise and uniform thin-film fabrication. Whether you're optimizing spray pyrolysis or exploring alternatives like CVD or sputtering, our expertise ensures you achieve the high-quality results your laboratory demands. Contact us today to discuss your specific application needs!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance