In short, the primary disadvantages of thermal evaporation are high impurity levels, significant limitations on the types of materials you can deposit, and the creation of low-density films with potentially poor uniformity. This technique struggles with high-melting-point materials and can introduce contamination from the heating source itself.

Thermal evaporation is valued for its simplicity and low cost, but this comes at a significant price. Its fundamental trade-off is sacrificing film purity, material versatility, and structural quality for operational ease and affordability.

The Challenge of Purity and Contamination

The most frequently cited drawback of thermal evaporation is its compromised purity, which stems directly from its operating principle.

High Impurity Levels

Compared to other physical vapor deposition (PVD) methods like sputtering or e-beam evaporation, thermal evaporation generally produces films with the highest levels of impurities. The relatively low vacuum and heating method contribute to this.

Contamination from the Source

The material to be deposited is placed in a "boat" or crucible, which is resistively heated. At high temperatures, the boat material itself can outgas or evaporate, becoming an unintentional contaminant in the final thin film.

Limitations in Film Quality and Structure

While simple to execute, the process offers less control over the final film properties compared to more advanced techniques.

Low-Density Films

The resulting films are often low-density and porous. While this can be improved by adding an ion-assist source, the inherent quality of a standard thermal evaporation process is lower than other PVD methods.

Moderate Internal Stress

Films deposited via thermal evaporation tend to exhibit moderate internal stress. This can be a critical failure point in applications where film adhesion and long-term stability are paramount.

Poor Uniformity Without Assistance

Achieving a uniform film thickness across a substrate is a major challenge. Without complex and expensive additions like planetary substrate holders and uniformity masks, the deposition is often inconsistent.

Constraints on Materials and Scalability

The heating mechanism places firm boundaries on what materials can be used and how effectively the process can be scaled.

Limited Material Selection

Thermal evaporation is fundamentally unsuitable for materials with very high melting points, such as refractory metals (e.g., tungsten, molybdenum). The resistive heating sources simply cannot reach the required temperatures efficiently or without heavy contamination.

Challenges with Organic Materials

Depositing polymers and other organic materials is problematic. The low thermal conductivity of these materials makes heating difficult, and the process can cause molecular decomposition or a decrease in molecular weight, altering the material's properties.

Limited Industrial Scalability

While excellent for lab-scale and some batch processes, the method's inherent non-uniformity and source limitations make it less scalable for large-area industrial applications compared to techniques like sputtering.

Understanding the Trade-offs: Simplicity vs. Performance

The disadvantages of thermal evaporation must be weighed against its primary advantage: simplicity.

The Cost-Benefit Equation

Thermal evaporation is relatively low-cost, simple, and robust. The equipment is less complex than sputtering or e-beam systems. This makes it an accessible entry point for thin-film deposition.

When Disadvantages Don't Matter

For certain applications, the drawbacks are acceptable. In decorative coatings for cosmetics or sporting goods, or basic light reflectors, the absolute purity and density of the film are less critical than the cost and visual appearance.

Mitigating the Downsides

It's important to recognize that a basic thermal evaporator can be upgraded. Adding ion-assist sources can improve film density, and planetary fixturing can improve uniformity. However, these additions increase cost and complexity, closing the gap with other PVD techniques.

Is Thermal Evaporation Right for Your Application?

Your decision should be based on a clear understanding of your project's non-negotiable requirements.

- If your primary focus is high purity and film density: Thermal evaporation is a poor choice; explore sputtering or e-beam evaporation instead.

- If your primary focus is depositing refractory metals or complex alloys: This technique is unsuitable due to its temperature limitations.

- If your primary focus is low-cost deposition of simple, low-melting-point metals: Thermal evaporation is a highly viable and cost-effective solution, especially for prototypes or decorative finishes.

- If your primary focus is depositing organic electronics (OLEDs): This method is used, but you must be prepared to manage the significant challenges of material decomposition and process control.

Ultimately, choosing thermal evaporation means consciously accepting its limitations in purity and performance in exchange for its simplicity and low cost.

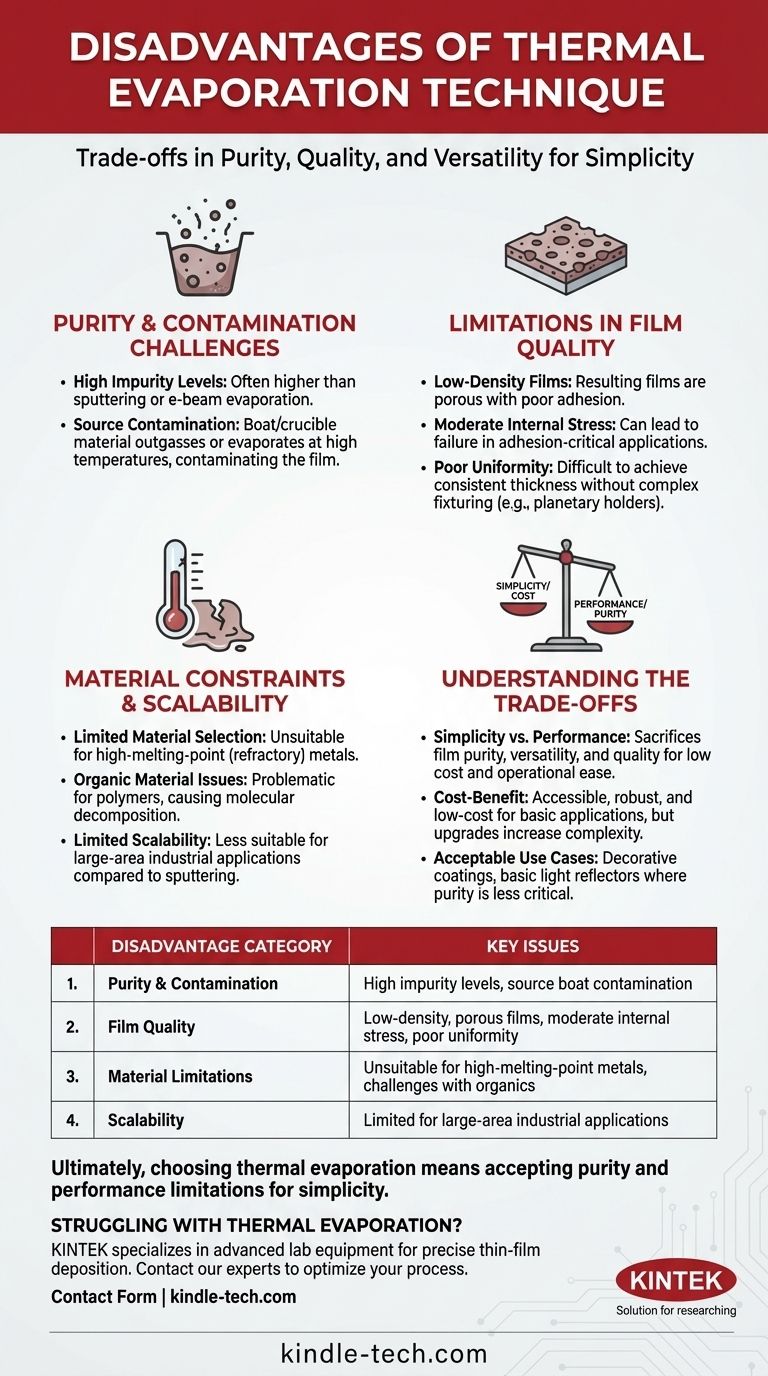

Summary Table:

| Disadvantage Category | Key Issues |

|---|---|

| Purity & Contamination | High impurity levels, source boat contamination |

| Film Quality | Low-density, porous films, moderate internal stress, poor uniformity |

| Material Limitations | Unsuitable for high-melting-point metals, challenges with organics |

| Scalability | Limited for large-area industrial applications |

Struggling with thermal evaporation's limitations? KINTEK specializes in advanced lab equipment and consumables for precise thin-film deposition. Whether you need higher-purity sputtering systems, e-beam evaporation tools, or expert guidance to select the right PVD technique for your materials, we have the solution. Contact our experts today to optimize your thin-film process and achieve superior results.

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is the thermal evaporation technique? A Guide to Thin-Film Deposition for Your Lab

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition

- What is the difference between sputtering and thermal evaporation? Choose the Right PVD Method for Your Thin Film

- What is the evaporation process in semiconductors? A Guide to Thin Film Deposition

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications