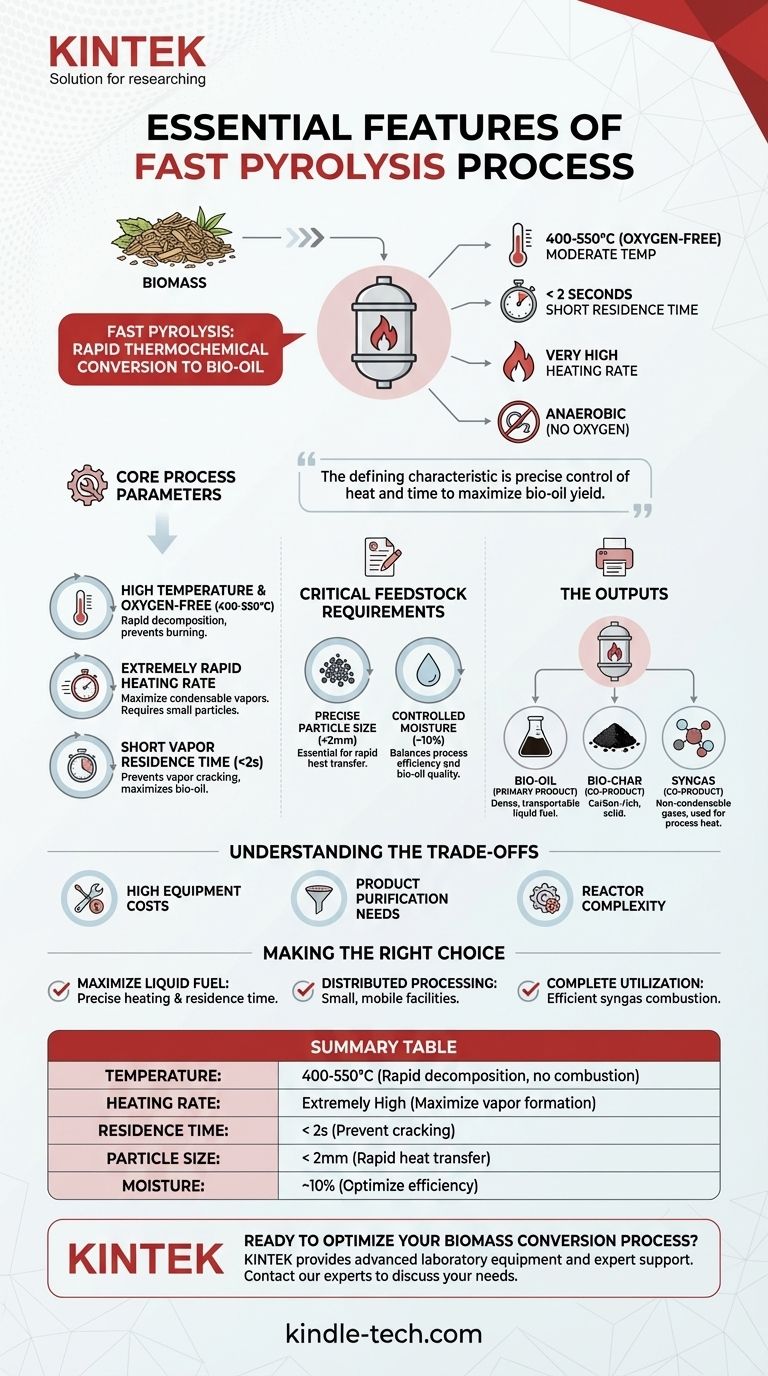

At its core, fast pyrolysis is a thermochemical process engineered to rapidly convert biomass into a liquid fuel known as bio-oil. The essential features are a very high heating rate, a moderate process temperature (around 400-550°C), a very short residence time for vapors (less than two seconds), and the complete absence of oxygen to prevent combustion.

The defining characteristic of fast pyrolysis is its precise control of heat and time. The entire process is optimized to rapidly break down biomass and immediately quench the resulting vapors into a liquid, maximizing bio-oil yield before those vapors can degrade further into less valuable gases.

Core Process Parameters

To achieve its goal of high liquid yield, fast pyrolysis operates under a set of stringent and carefully controlled conditions. These parameters distinguish it from slower pyrolysis methods, which favor char production.

High Temperature in an Oxygen-Free Environment

The process operates at temperatures between 400-550°C. This range is hot enough to cause rapid thermal decomposition of the biomass feedstock.

Crucially, this heating occurs in an anaerobic (oxygen-free) environment. This prevents the biomass from burning and ensures it breaks down chemically into the desired products.

Extremely Rapid Heating Rate

A key feature of this technology is the high heating rate. The biomass particles must be brought to the target temperature as quickly as possible to maximize the formation of condensable vapors.

This rapid energy transfer is why feedstock preparation, particularly particle size, is so critical.

Short Vapor Residence Time

Once the biomass decomposes into hot vapors, they are allowed to remain in the high-temperature reactor for a very short period—typically less than two seconds.

This short residence time is intentional. It prevents secondary reactions or "cracking," where the valuable vapors would break down further into non-condensable, lower-value gases. The vapors are then rapidly cooled, or "quenched," to condense them into liquid bio-oil.

Critical Feedstock Requirements

The efficiency and success of fast pyrolysis depend heavily on the physical properties of the raw biomass being processed.

Precise Particle Size

The process requires very small feedstock particles, generally up to 2 mm in diameter.

Small particles have a high surface-area-to-volume ratio, which is essential for the rapid heat transfer needed to achieve the required heating rates.

Controlled Moisture Content

The ideal moisture content for feedstock is around 10%.

If the moisture is too high, the process wastes energy creating steam and produces an excessive amount of water in the final bio-oil. If it's too low, the feedstock can become dusty and difficult to handle.

The Outputs of Fast Pyrolysis

While the primary goal is liquid fuel, the process inherently creates a portfolio of products, all of which have potential uses.

Bio-oil (The Primary Product)

The main product is bio-oil, a dark, dense liquid biofuel. Liquid fuel offers significant advantages in storage and transportation compared to solid biomass or gaseous products.

Bio-char and Syngas (Co-products)

Fast pyrolysis also produces a solid carbon-rich material called bio-char and non-condensable synthesis gases (syngas), including methane, hydrogen, and carbon monoxide.

A key advantage of the process is that the syngas can be combusted on-site to provide the heat required to run the reactor, making the system more energy-efficient and potentially self-sustaining.

Understanding the Trade-offs

While powerful, fast pyrolysis technology comes with specific challenges and considerations that must be addressed for successful implementation.

Equipment and Operational Costs

The specialized reactors and control systems required to maintain precise temperature and timing can lead to high initial equipment costs.

Product Purification Needs

The raw bio-oil produced is not a "drop-in" fuel. It is acidic, contains water, and can be unstable. It often requires separation, purification, or upgrading before it can be used in conventional engines or refineries.

Reactor Complexity

To meet the stringent process requirements, a wide range of reactor configurations have been developed. While this offers flexibility, it also adds a layer of technical complexity when selecting or designing a system.

Making the Right Choice for Your Goal

The application of fast pyrolysis should be aligned with your strategic objectives for biomass conversion.

- If your primary focus is maximizing liquid fuel production: Prioritize a reactor design that offers precise control over heating rates and vapor residence time to maximize bio-oil yield.

- If your primary focus is distributed biomass processing: Leverage the potential for small, mobile-scale facilities that can produce dense bio-oil near the biomass source, reducing transportation costs for raw materials.

- If your primary focus is complete resource utilization: Design a system that efficiently combusts the co-produced syngas for process heat and finds a valuable application for the resulting bio-char.

Ultimately, fast pyrolysis is a highly effective technology for converting the entirety of a biomass feedstock into more valuable and transportable energy products.

Summary Table:

| Feature | Parameter | Purpose |

|---|---|---|

| Temperature | 400-550°C | Rapid thermal decomposition without combustion |

| Heating Rate | Extremely High | Maximize condensable vapor formation |

| Vapor Residence Time | < 2 seconds | Prevent vapor cracking into low-value gases |

| Feedstock Particle Size | Up to 2 mm | Ensure rapid heat transfer |

| Moisture Content | ~10% | Optimize process efficiency and bio-oil quality |

| Primary Product | Bio-oil | Dense, transportable liquid fuel |

| Co-products | Bio-char & Syngas | Enable energy self-sufficiency and resource utilization |

Ready to optimize your biomass conversion process?

At KINTEK, we specialize in providing the advanced laboratory equipment and expert support you need to develop and scale your fast pyrolysis operations. Whether you are focused on maximizing bio-oil yield, designing a distributed processing system, or achieving complete resource utilization, our team is here to help.

We supply robust reactors, precise temperature control systems, and consumables tailored for thermochemical processes. Let KINTEK be your partner in turning biomass into valuable energy products efficiently and reliably.

Contact our experts today to discuss your specific needs and discover how our solutions can drive your success.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Spark Plasma Sintering Furnace SPS Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time