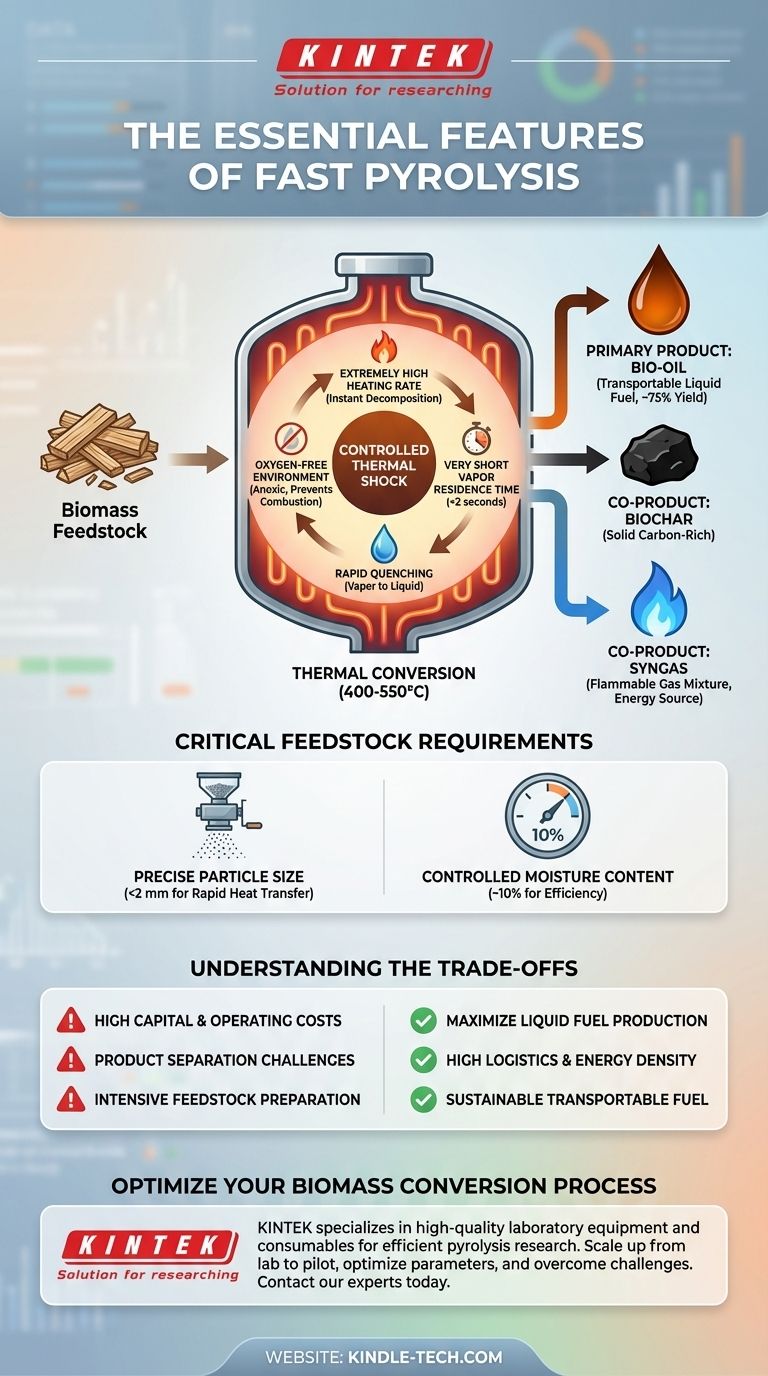

At its core, fast pyrolysis is a thermal conversion process defined by four essential features: extremely high heating rates, a moderate-to-high process temperature (400-550°C), a very short residence time for vapors (less than 2 seconds), and the complete absence of oxygen. These conditions are not arbitrary; they are precisely engineered to rapidly decompose biomass and maximize the production of a liquid product known as bio-oil.

The central purpose of fast pyrolysis is to apply a controlled "thermal shock" to biomass. This process intentionally interrupts the material's decomposition at an intermediate stage, capturing valuable liquid compounds before they have a chance to break down further into lower-value gas and solid char.

The Core Process Parameters

To achieve its primary goal of maximizing liquid yield, fast pyrolysis relies on a delicate balance of carefully controlled process conditions. Each parameter serves a specific function in manipulating the chemical decomposition of the biomass feedstock.

High Heating Rate and Temperature

The process operates by heating biomass to a target temperature between 400-550°C. Crucially, this must happen at an extremely high rate. The rapid transfer of heat is necessary to break down the solid structure of the biomass almost instantaneously.

Short Residence Time

Once the biomass vaporizes, these hot vapors remain in the reactor for an exceptionally short period—typically less than two seconds. This short residence time is a defining feature, as it prevents secondary reactions where the valuable liquid precursors would otherwise "crack" into non-condensable gases.

Oxygen-Free Environment

Fast pyrolysis is, by definition, an anoxic process, meaning it occurs in the absence of oxygen. This prevents combustion (burning) and ensures that the biomass decomposes thermally into its constituent chemical components rather than simply releasing its energy as heat.

Rapid Quenching

Following their brief time in the reactor, the hot vapors are cooled and condensed very quickly. This "quenching" step is what turns the vapor-phase products into the final liquid bio-oil, effectively locking them into their liquid state.

Critical Feedstock Requirements

The success of fast pyrolysis is highly dependent on the preparation of the raw biomass before it ever enters the reactor. The process's high speed demands a consistent and properly conditioned feedstock.

Precise Particle Size

To facilitate the necessary rapid heat transfer, the biomass feedstock must be ground into very small particles, often less than 2 mm in diameter. Small particles have a high surface-area-to-volume ratio, allowing heat to penetrate and decompose them almost instantly.

Controlled Moisture Content

The ideal moisture content for most fast pyrolysis systems is around 10%. If the feedstock is too wet, a significant amount of energy is wasted creating steam instead of valuable bio-oil. If it is too dry, it can create excessive dust and complicate handling.

The Signature Products of Fast Pyrolysis

The output of the process is a mixture of liquid, solid, and gas products, each with a distinct role and value. While the process can be tuned, the primary goal is always to maximize the liquid fraction.

Bio-oil: The Primary Goal

The main product, often yielding up to 75% of the feedstock's weight, is bio-oil. This dense, dark liquid offers significant advantages over raw biomass because it can be easily stored and transported, similar to conventional fossil fuels.

Biochar and Syngas: The Co-products

The process also creates biochar (a solid, carbon-rich charcoal) and non-condensable syngas (a mixture of flammable gases like hydrogen, methane, and carbon monoxide). These are not waste products; the syngas is typically burned to provide the heat for the reactor, making the process partially energy self-sufficient.

Understanding the Trade-offs

While powerful, fast pyrolysis is not without its challenges. Understanding its limitations is key to evaluating its practical application.

High Equipment and Operating Costs

The sophisticated reactors required to achieve precise temperature control and rapid heat transfer are expensive to build and operate. This represents a significant capital investment barrier.

The Challenge of Product Separation

The raw output is a mix of bio-oil, char, and gas that must be efficiently separated. Furthermore, the bio-oil itself is a complex mixture that often requires significant purification and upgrading before it can be used in conventional engines or refineries.

Feedstock Preparation Demands

The strict requirements for small particle size and low moisture mean that an extensive and energy-intensive pre-processing step is necessary. Grinding and drying the raw biomass adds cost and complexity to the overall operation.

Making the Right Choice for Your Goal

Your decision to use or invest in fast pyrolysis technology should be guided by your specific objective.

- If your primary focus is maximizing liquid fuel production from biomass: Fast pyrolysis is the most direct thermal route, but you must invest in precise feedstock preparation and efficient vapor quenching systems.

- If your primary focus is logistics and energy density: The ability of fast pyrolysis to convert bulky, low-density biomass into a transportable liquid fuel is its single greatest strategic advantage.

- If your primary focus is evaluating investment risk: The main hurdles are the initial capital for sophisticated reactors and the downstream costs associated with separating and upgrading the raw bio-oil.

Understanding these features allows you to see fast pyrolysis not as a simple heater, but as a high-speed chemical refinery engineered to convert solid biomass into a transportable liquid fuel.

Summary Table:

| Feature | Parameter | Purpose |

|---|---|---|

| Heating Rate | Extremely High | Instantaneous biomass decomposition |

| Temperature | 400-550°C | Optimal for liquid yield |

| Vapor Residence Time | < 2 seconds | Prevents secondary cracking |

| Atmosphere | Oxygen-Free (Anoxic) | Prevents combustion |

| Feedstock Size | < 2 mm | Ensures rapid heat transfer |

| Moisture Content | ~10% | Maximizes process efficiency |

| Primary Product | Bio-oil (up to 75% yield) | Transportable liquid fuel |

Ready to optimize your biomass conversion process?

At KINTEK, we specialize in providing high-quality laboratory equipment and consumables essential for researching and developing efficient pyrolysis systems. Whether you are scaling up from lab to pilot or optimizing your process parameters, our reactors, temperature control systems, and analytical tools are designed for precision and reliability.

We help our customers in the biofuels and renewable energy sectors overcome challenges in feedstock preparation, product separation, and process control. Let our expertise support your journey in creating sustainable, transportable bio-oil.

Contact our experts today to discuss how KINTEK's solutions can enhance your fast pyrolysis research and development.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory High Pressure Vacuum Tube Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- What causes increase in ash content? Uncover the hidden culprits that harm your equipment.

- How long should a furnace take to raise the temperature? Key Factors for Optimal Heating Speed

- What is the heating range of a muffle furnace? From 800°C to 1800°C for Your Lab Needs

- What is the structure of a muffle furnace? A Guide to Its Core Components and Design

- Why do we use a muffle furnace? For Pure, Precise, and Contaminant-Free High-Temperature Processing