The most common examples of Physical Vapor Deposition (PVD) are sputter deposition, thermal evaporation, and ion plating. These are all vacuum-based processes used to create high-performance thin films. They achieve this by converting a solid source material into a vapor, transporting it across a vacuum chamber, and allowing it to condense onto the surface of a target component, known as the substrate.

The key to understanding PVD is not to memorize a list of techniques, but to recognize that they all follow the same core principle: physically moving material from a source to a substrate without chemical reactions. The specific examples simply represent different methods for achieving the initial vaporization step.

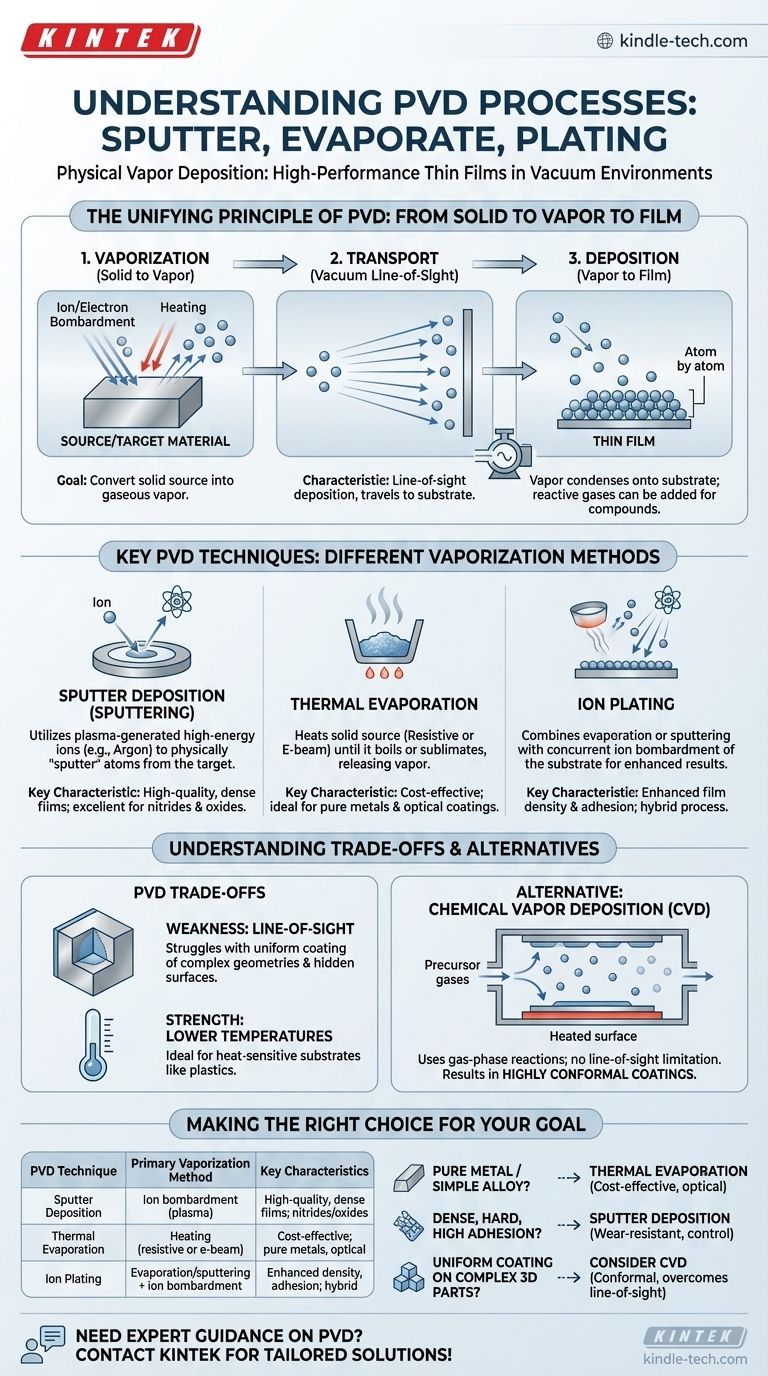

The Unifying Principle of PVD: From Solid to Vapor to Film

Every PVD process, regardless of the specific technique, fundamentally consists of three critical stages that occur within a high-vacuum environment. The vacuum is essential to prevent the vaporized coating material from colliding with and reacting to air molecules.

Stage 1: Vaporization

This is the step where the different PVD techniques diverge. The goal is to convert a solid source material, called a "target" or "source," into a gaseous vapor. This is achieved by bombarding the material with a high-energy source, such as ions or electrons, or by heating it until it evaporates.

Stage 2: Transport

Once vaporized, the atoms or molecules of the coating material travel through the vacuum chamber. This journey is typically in a straight line, which is a defining characteristic of PVD known as "line-of-sight" deposition.

Stage 3: Deposition

When the vaporized material reaches the substrate (the part to be coated), it condenses back into a solid state. This process builds up, atom by atom, to form a thin, highly-adherent film on the substrate's surface. In some cases, a reactive gas like nitrogen is introduced to form compound coatings like titanium nitride.

A Closer Look at Key PVD Techniques

The "examples" of PVD are really just different methods for accomplishing the vaporization stage. The two most dominant techniques are sputtering and evaporation.

Sputter Deposition (Sputtering)

Sputtering is arguably the most versatile and widely used PVD process. It involves creating a plasma, typically from an inert gas like Argon.

The plasma generates high-energy ions that are accelerated toward the source material (the target). When these ions strike the target, they physically knock out, or "sputter," atoms from the source material, ejecting them into the vacuum chamber like billiard balls. These sputtered atoms then deposit onto the substrate.

Thermal Evaporation

Thermal evaporation is a more straightforward process. The solid source material is heated in the vacuum until it begins to boil or sublimate, releasing a vapor.

The heating is typically done in one of two ways: either by passing a high current through a resistive element holding the material (resistive heating) or by bombarding it with a high-energy electron beam (e-beam evaporation). This vapor then travels to the substrate and condenses.

Ion Plating

Ion Plating is an enhanced PVD process that combines elements of either evaporation or sputtering with a concurrent ion bombardment of the substrate. By applying a high negative voltage to the substrate, it attracts the positively charged ions from the plasma, leading to a denser, more adherent film as it forms.

Understanding the Trade-offs

No single technique is universally superior. The choice of PVD method—or whether to use PVD at all—depends on the desired outcome and the constraints of the application. The primary alternative to PVD is Chemical Vapor Deposition (CVD).

The Weakness of PVD: Line-of-Sight

Because PVD relies on the physical transport of atoms in a straight line, it struggles to uniformly coat complex, three-dimensional shapes with hidden surfaces or deep crevices. The coating will be thickest on surfaces directly facing the source and thinnest or absent on shadowed areas.

The Strength of PVD: Lower Temperatures

PVD processes can be conducted at relatively low temperatures. This makes them ideal for coating substrates that cannot withstand the high heat required for many CVD processes, such as plastics or certain heat-treated metal alloys.

When to Consider Chemical Vapor Deposition (CVD)

CVD does not have the line-of-sight limitation. In CVD, precursor gases flow into a chamber and react on the hot substrate surface to form the film. This allows the gas to penetrate complex geometries, resulting in a highly conformal coating that is uniform across all surfaces.

Making the Right Choice for Your Goal

Selecting the correct method requires balancing the properties of the desired film with the geometry of the part and the nature of the substrate material.

- If your primary focus is depositing a pure metal or a simple alloy: Thermal Evaporation is often a direct and cost-effective method, especially for optical coatings.

- If your primary focus is creating a very dense, hard, or high-adhesion film (like a nitride or oxide): Sputter Deposition offers superior process control and results in higher-quality films for wear-resistant applications.

- If your primary focus is achieving a perfectly uniform coating on a complex 3D part: You should investigate Chemical Vapor Deposition (CVD) as its gas-phase nature overcomes the line-of-sight limitations of PVD.

Ultimately, choosing the right technique depends on a clear understanding of your material, substrate, and desired film properties.

Summary Table:

| PVD Technique | Primary Vaporization Method | Key Characteristics |

|---|---|---|

| Sputter Deposition | Ion bombardment (plasma) | High-quality, dense films; excellent for nitrides/oxides |

| Thermal Evaporation | Heating (resistive or e-beam) | Cost-effective; ideal for pure metals and optical coatings |

| Ion Plating | Evaporation/sputtering + ion bombardment | Enhanced film density and adhesion; hybrid process |

Need expert guidance on selecting the right PVD process for your lab's specific application? KINTEK specializes in lab equipment and consumables, providing tailored solutions for your thin film deposition needs. Our expertise ensures you achieve optimal coating performance, whether for wear resistance, optical properties, or material research. Contact us today to discuss how we can support your laboratory's success!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Evaporation Boat for Organic Matter

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating