In short, ball mill grinding efficiency is determined by a precise balance of factors. The most critical of these are the mill's rotational speed, the properties of the grinding media (its size and fill volume), and the characteristics of the material being processed, including its feed rate and hardness.

The core principle of effective ball milling is not about maximizing force, but about optimizing motion. True efficiency is found within a specific operational window where the grinding media cascades and tumbles correctly, creating the ideal combination of impact and abrasion to break down particles.

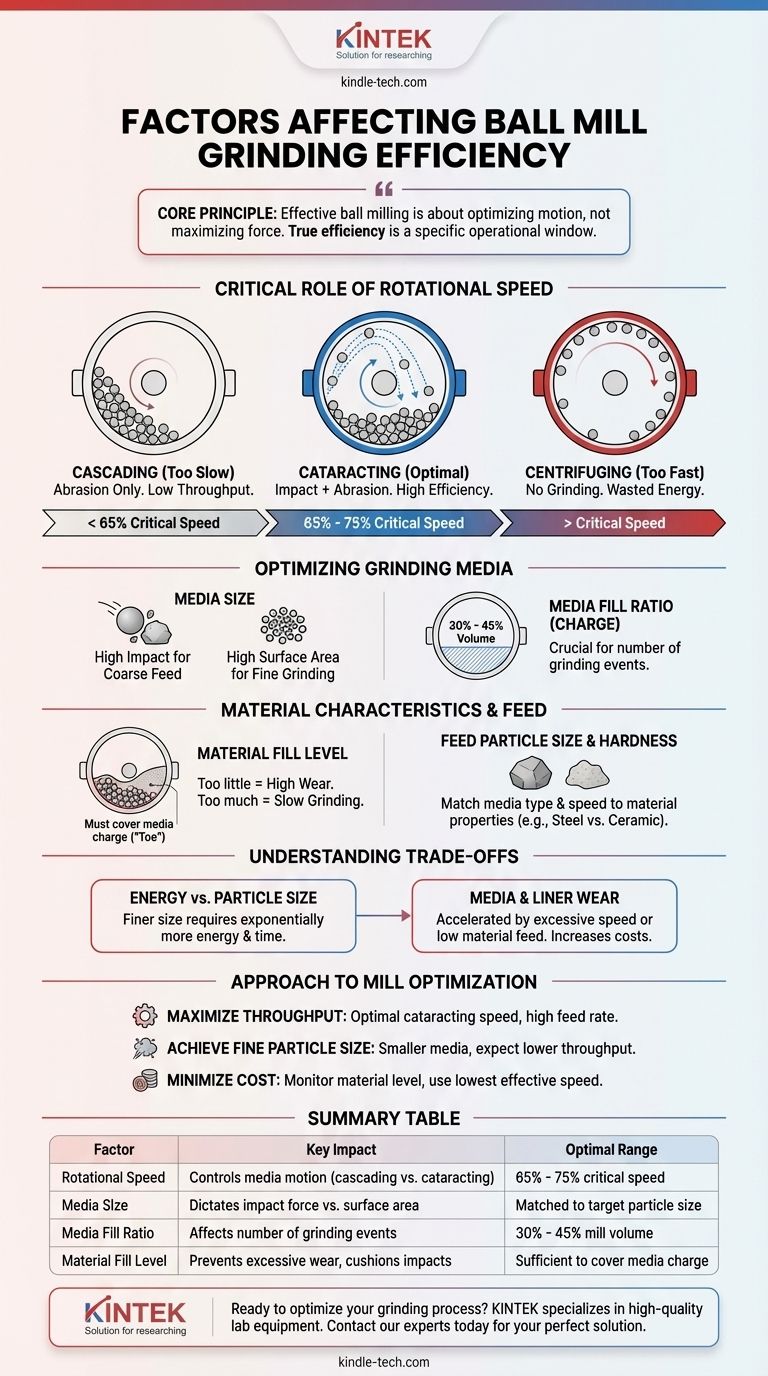

The Critical Role of Rotational Speed

The speed at which the mill rotates is the single most influential factor in grinding performance. It directly controls the behavior of the grinding media inside the mill, a concept best understood by its relationship to "critical speed."

Understanding Critical Speed

Critical speed is the theoretical velocity at which the outermost layer of grinding balls would be pinned to the mill's inner wall by centrifugal force, ceasing all grinding action.

Effective grinding typically occurs between 65% and 75% of this critical speed.

The Cascading Motion (Too Slow)

When the mill rotates too slowly, the grinding media is lifted only a short distance up the side of the drum before it gently tumbles or slides back down.

This motion, known as cascading, results in grinding primarily through abrasion. It is inefficient for breaking down larger particles and leads to low throughput.

The Cataracting Motion (Optimal)

At the optimal speed, the media is lifted high enough to break contact with the wall and follow a parabolic path down onto the material bed. This is called cataracting.

This action combines the high-energy impact forces needed to fracture coarse particles with the abrasion from the tumbling media, yielding the most efficient grinding performance.

The Centrifuging Motion (Too Fast)

If the mill speed approaches or exceeds the critical speed, the grinding media becomes pinned to the liner.

No tumbling or impact occurs, and the grinding action effectively stops. This not only halts production but also wastes significant energy.

Optimizing the Grinding Media

The grinding media—the balls themselves—are the engine of the grinding process. Their size, quantity, and type must be carefully matched to the operational goal.

Media Size and its Impact

The size of the grinding media dictates the nature of the force applied.

Larger balls deliver higher impact energy, which is necessary for breaking down coarse feed material. Smaller balls provide a greater total surface area, which is more effective for the fine grinding of smaller particles.

The Media Filling Ratio (The Charge)

The volume of the mill occupied by the grinding media, known as the charge or filling ratio, is crucial. This is typically between 30% and 45% of the mill's internal volume.

Too low a charge reduces the number of grinding events, lowering efficiency. Too high a charge restricts the motion of the media, preventing it from cataracting properly.

Material Characteristics and Feed

The material being ground is not a passive element; its properties and how it is introduced into the mill are fundamental to the process.

The Material Filling Level

The amount of material inside the mill must be sufficient to cover the grinding media charge, creating what is known as the "toe" of the load.

Too little material exposes the media and mill liners to direct, high-energy impacts, causing rapid wear. Too much material will cushion the impacts excessively, slowing the grinding rate.

Feed Particle Size and Hardness

The setup of the mill must be matched to the material's properties.

Harder materials may require denser grinding media (e.g., steel instead of ceramic) or a different rotational speed to achieve the necessary impact energy for effective breakage.

Understanding the Trade-offs

Optimizing a ball mill is an exercise in balancing competing factors. An improvement in one area can often create a challenge in another.

Energy Consumption vs. Particle Size

Grinding is an energy-intensive process. Achieving a finer particle size requires exponentially more energy and time, as the probability of media impacting an already small particle decreases.

Media and Liner Wear

The constant impact and abrasion that enables grinding also causes wear on the grinding media and the mill's protective liners.

Operating at excessive speeds or with insufficient material feed dramatically accelerates this wear, increasing maintenance costs and potential product contamination.

How to Approach Mill Optimization

Your specific adjustments should be guided by your primary objective. Use these principles as a starting point for refining your process.

- If your primary focus is maximizing throughput: Ensure the mill operates in the optimal cataracting speed range (65-75% of critical speed) and that the material feed rate is high enough to avoid inefficient over-grinding.

- If your primary focus is achieving a very fine particle size: Use a charge of smaller grinding media to maximize surface area for abrasion, but be prepared for lower throughput and higher energy consumption.

- If your primary focus is minimizing operational cost: Pay close attention to the material level to avoid excessive media and liner wear, and operate at the lowest speed that still provides effective grinding.

Ultimately, mastering your ball mill operation comes from understanding that each factor is a lever you can pull to achieve a specific, controlled outcome.

Summary Table:

| Factor | Key Impact | Optimal Range |

|---|---|---|

| Rotational Speed | Controls media motion (cascading vs. cataracting) | 65% - 75% of critical speed |

| Media Size | Dictates impact force (large balls) vs. surface area (small balls) | Matched to target particle size |

| Media Fill Ratio | Affects number of grinding events and media motion | 30% - 45% of mill volume |

| Material Fill Level | Prevents excessive wear or cushions impacts | Sufficient to cover the media charge |

Ready to optimize your grinding process and boost your lab's productivity? The precise balance of speed, media, and material is key to efficient particle size reduction. KINTEK specializes in high-quality lab equipment and consumables, including ball mills and grinding media, to help you achieve consistent, reliable results.

Contact our experts today to discuss your specific application and find the perfect solution for your laboratory needs.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is the specific role of a high-energy planetary ball mill in the synthesis of Ag-doped sulfide solid-state electrolytes?

- What is the function of a high-energy planetary ball mill in zirconium-doped CaO synthesis? Optimize Material Stability

- How does a planetary ball mill enhance the electrocatalytic activity of La0.6Sr0.4CoO3-δ? Boost Your Catalyst Performance

- What role does a planetary ball mill play in SHS? Optimize Powder Activation for Superior Alloy Synthesis

- What is the role of a planetary ball mill in the preparation of NiCr-Al2O3-SrCO3 composite powders? Enhanced Homogeneity