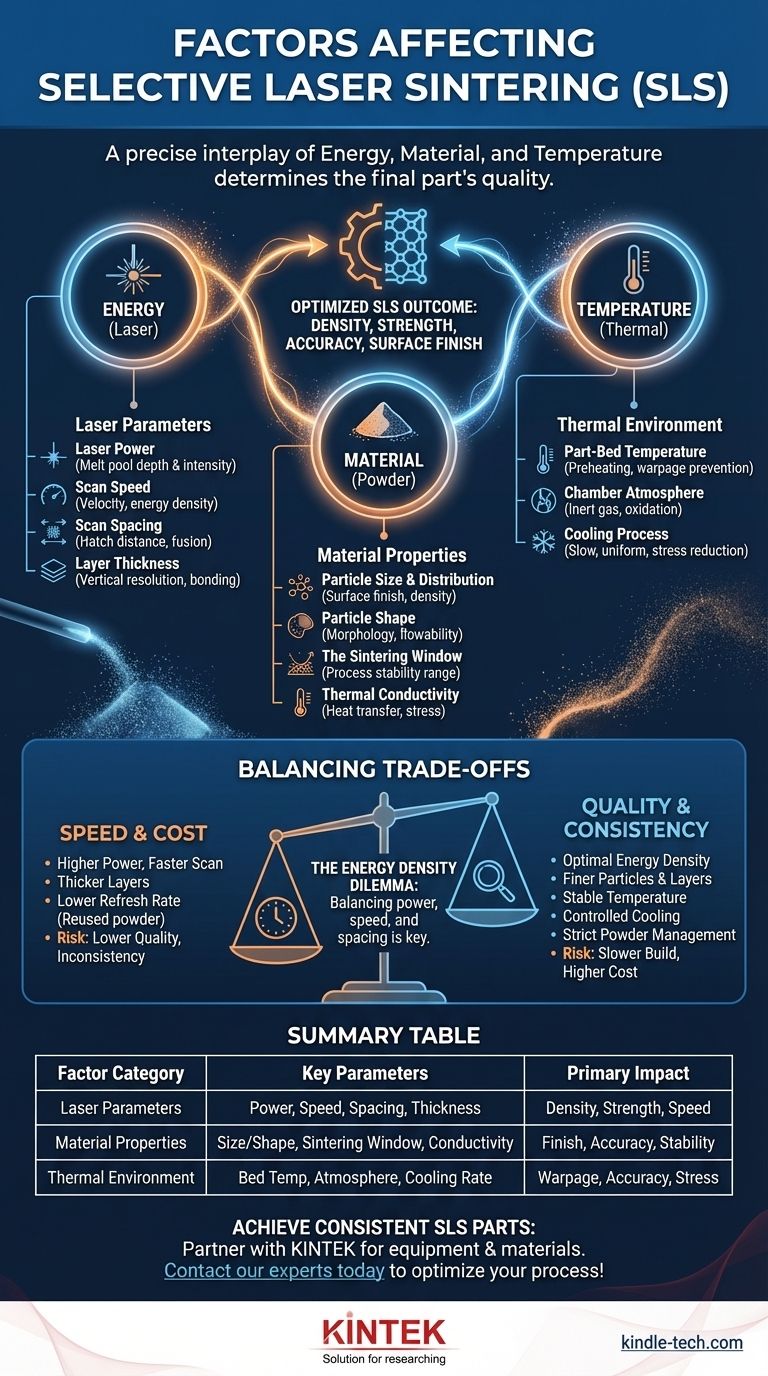

To control the outcome of selective laser sintering (SLS), you must manage a precise interplay of energy, material, and temperature. The most critical factors are the laser parameters (power, scan speed, scan spacing), the physical and thermal properties of the polymer powder, and the thermal management of the build chamber. These elements work in concert to determine the final part's density, mechanical strength, dimensional accuracy, and surface finish.

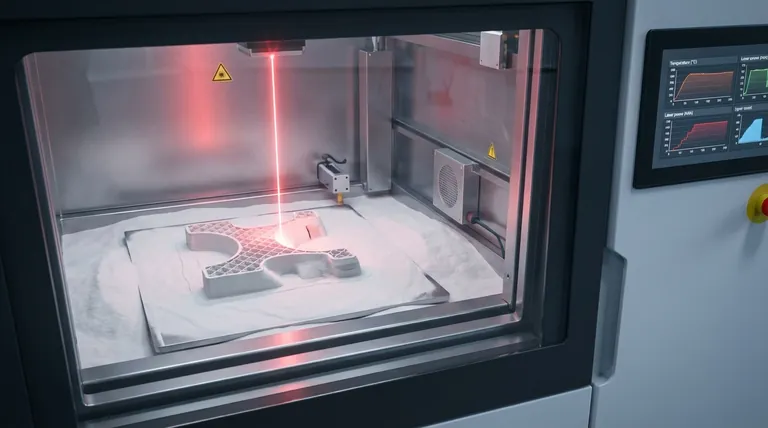

Selective Laser Sintering is not just about melting powder; it's a thermal management challenge. Mastering the balance between the laser energy you input and the thermal properties of the powder bed is the fundamental key to producing strong, accurate, and repeatable parts.

The Core Pillars of SLS: Energy, Material, and Temperature

Every successful SLS print is built on the careful control of three fundamental pillars. Understanding how they interact is essential for troubleshooting and process optimization.

Laser Parameters: The Energy Input

The laser is the tool that provides the energy for sintering. How that energy is delivered dictates whether particles fuse correctly or the part fails.

- Laser Power: This determines the depth and intensity of the melt pool. Higher power allows for faster scanning but can degrade or burn the polymer if not balanced with speed.

- Scan Speed: This is the velocity of the laser beam as it draws a cross-section. Scan speed is inversely related to energy density; a slower speed delivers more energy to a given area, promoting better fusion.

- Scan Spacing (or Hatch Distance): This is the distance between adjacent laser paths. If the spacing is too wide, it creates voids between scan lines, resulting in a porous and weak part. If it's too narrow, excessive energy can build up, causing distortion.

- Layer Thickness: This sets the vertical resolution of the part. Thicker layers allow for faster builds but require more laser energy to penetrate and bond to the layer below, increasing the risk of delamination.

Material Properties: The Foundation of the Part

The powder itself is not a passive medium. Its characteristics have a profound impact on how it absorbs energy, flows within the machine, and solidifies into a final part.

Powder Particle Characteristics

- Particle Size and Distribution: A fine powder with a narrow size distribution generally leads to a smoother surface finish and higher part density. However, excessively fine particles can have poor flowability, making it difficult to spread a uniform layer.

- Particle Shape (Morphology): Highly spherical particles exhibit the best flowability. This allows them to pack together densely and evenly, which is critical for creating a uniform powder bed and, consequently, a stronger, more consistent part.

Thermal Behavior of the Powder

- The Sintering Window: This is the crucial temperature range between the material's crystallization point (when it solidifies) and its melting point. A wider sintering window makes the process more stable and less sensitive to minor temperature fluctuations.

- Thermal Conductivity: This measures how well the powder transfers heat. Low thermal conductivity helps confine the heat to the laser spot, but it can also contribute to thermal stress if heat isn't dissipated correctly.

The Thermal Environment: Managing Heat Flow

The temperature of the entire build volume, not just the spot under the laser, is arguably the most critical factor for producing accurate, stress-free parts.

Part-Bed Temperature

- The entire powder bed is preheated to a temperature just below the material's melting point. This reduces the energy required from the laser and, most importantly, minimizes the thermal gradient between the sintered part and the surrounding powder, which is the primary defense against warpage.

Chamber Atmosphere

- Most engineering polymers, like nylon (PA), will oxidize at high temperatures. To prevent this material degradation, the build chamber is filled with an inert gas, typically nitrogen, creating an oxygen-deprived environment.

Cooling Process

- The cooling phase is as critical as the printing phase. Parts must be cooled slowly and uniformly within the powder cake. A rapid or uneven cooling rate will introduce internal stresses, causing significant warpage and potential cracking.

Understanding the Trade-offs: Speed vs. Quality

Optimizing the SLS process always involves balancing competing factors. There is rarely a single "best" setting, only the best setting for a specific goal.

The Energy Density Dilemma

Energy Density is a formula that relates laser power, scan speed, and scan spacing. Too little energy density results in "under-sintering," where powder particles are not fully fused, creating a weak, porous part. Too much energy density causes "over-sintering," which can burn the polymer, reduce mechanical properties, and cause part distortion.

Accuracy vs. Warpage

Maintaining a high part-bed temperature is excellent for preventing warpage, but it can have a downside. The elevated temperature can cause heat to "bleed" into the unsintered powder around fine features, causing them to lose definition or "grow" beyond their intended dimensions.

Cost vs. Consistency (Powder Refresh Rate)

Reusing unsintered powder is essential for making SLS cost-effective. However, the powder degrades slightly with each thermal cycle. The refresh rate—the ratio of new (virgin) powder to used powder—is a critical operational factor. A low refresh rate saves money but can lead to inconsistent part quality over time as the material properties drift.

Optimizing Your SLS Process

To achieve your desired outcome, focus on the factors that most directly influence your primary goal.

- If your primary focus is mechanical strength: Prioritize achieving optimal energy density to ensure full fusion between particles and layers by carefully tuning laser power and scan speed.

- If your primary focus is dimensional accuracy and preventing warpage: Master your thermal management by ensuring a stable part-bed temperature and implementing a slow, controlled cooling cycle.

- If your primary focus is surface finish: Use powders with fine, spherical particles and consider smaller layer thicknesses, understanding this will increase print time.

- If your primary focus is process repeatability and cost-efficiency: Implement a strict powder management protocol with a consistent refresh rate to counteract material degradation.

Ultimately, successful SLS printing is a systematic process of balancing these competing factors to meet the specific demands of your application.

Summary Table:

| Factor Category | Key Parameters | Primary Impact on Part |

|---|---|---|

| Laser Parameters | Power, Scan Speed, Scan Spacing, Layer Thickness | Density, Mechanical Strength, Build Speed |

| Material Properties | Particle Size/Shape, Sintering Window, Thermal Conductivity | Surface Finish, Dimensional Accuracy, Process Stability |

| Thermal Environment | Part-Bed Temperature, Chamber Atmosphere, Cooling Rate | Warpage Prevention, Dimensional Accuracy, Internal Stress |

Achieve consistent, high-quality SLS parts with the right equipment and consumables. KINTEK specializes in lab equipment and materials, providing the tools and expertise to optimize your selective laser sintering process. Whether you need reliable powder handling solutions or insights into thermal management, our team is here to support your laboratory's success. Contact our experts today to discuss your specific SLS challenges and goals!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- What is the function of laboratory autoclaves in SCWR research? Predict Material Compatibility and Corrosion Kinetics

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy