To understand a ball mill is to understand the variables that control its performance. The factors affecting a ball mill's grinding efficiency can be organized into three primary categories: the characteristics of the material being ground, the physical equipment and its components, and the operational conditions you control during the process.

The effectiveness of a ball mill is not determined by a single setting, but by the precise balance between rotational speed, the type and volume of grinding media, and the properties of the feed material. Mastering this interplay is the key to achieving the desired particle size efficiently.

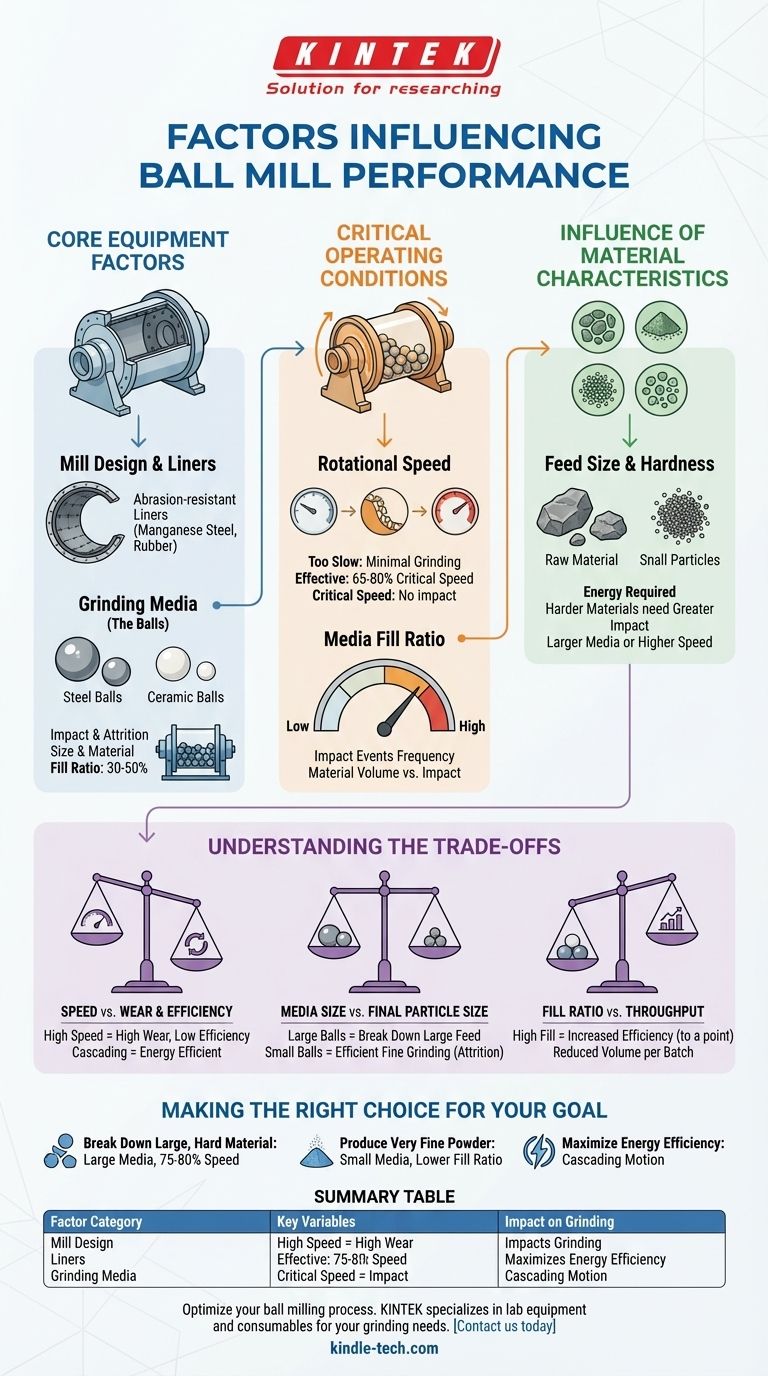

Core Equipment Factors

The physical design of the ball mill and its components establishes the foundation for the grinding process.

Mill Design and Liners

A ball mill is fundamentally a hollow cylindrical shell that rotates on its axis. The inside of this shell is protected by abrasion-resistant liners, often made of materials like manganese steel or specialized rubber, which endure the constant impact of the grinding process.

Grinding Media (The Balls)

The grinding media—typically steel or ceramic balls—are the heart of the operation. They are responsible for reducing material size through impact (crushing) and attrition (rubbing).

The size and material of the balls are chosen based on the grinding application. The fill ratio, which is the percentage of the mill's volume occupied by the media, is typically between 30% and 50%.

Critical Operating Conditions

These are the variables an operator directly manipulates to control the grinding outcome.

Rotational Speed

The speed at which the mill rotates is arguably the most critical operational factor. It dictates how the grinding media moves inside the cylinder.

Too slow, and the balls will simply roll over each other at the bottom of the mill, resulting in minimal grinding.

The Concept of Critical Speed

Critical speed is the theoretical speed at which the centrifugal force pins the grinding media against the inner wall of the mill, causing them to travel in a full circle without falling.

At this speed, no impact occurs, and grinding ceases entirely. Effective grinding happens at a percentage of this critical speed, typically 65-80%, which allows the balls to be carried up the wall and then cascade or cataract down, creating the necessary impact forces.

Media Fill Ratio

The fill ratio, or charge volume, determines the number of impact events. A higher fill ratio increases the frequency of ball-on-ball and ball-on-material collisions but reduces the amount of space available for the material itself.

The Influence of Material Characteristics

The material you are trying to grind has its own properties that directly influence the process.

Feed Size and Hardness

The initial particle size and hardness of the material determine the energy required for size reduction. Harder materials necessitate greater impact forces, which may require larger grinding media or higher operational speeds.

Understanding the Trade-offs

Optimizing a ball mill requires balancing competing factors. There is rarely a single "best" setting.

Speed vs. Wear and Efficiency

Running the mill at a higher percentage of its critical speed increases impact energy, but it also dramatically increases wear on the grinding media and the mill liners. The most energy-efficient grinding often occurs at a speed that creates a cascading motion rather than a more violent cataracting one.

Media Size vs. Final Particle Size

Large grinding balls are effective at breaking down large feed particles due to their high impact energy.

However, smaller grinding balls provide a much greater total surface area, making them far more efficient for fine grinding and achieving a very small final particle size through attrition.

Fill Ratio vs. Throughput

A higher fill ratio can increase grinding efficiency up to a point, but it also reduces the volume of material that can be processed in a single batch. Finding the optimal load is key to maximizing overall plant throughput.

Making the Right Choice for Your Goal

Your operational settings should be a direct reflection of your desired outcome.

- If your primary focus is breaking down large, hard material: Prioritize larger grinding media and operate at a higher percentage of critical speed (e.g., 75-80%) to maximize impact forces.

- If your primary focus is producing a very fine powder: Use smaller grinding media to maximize surface area and attrition, potentially with a slightly lower fill ratio to ensure proper material movement.

- If your primary focus is maximizing energy efficiency: Operate at a speed that promotes a cascading motion rather than a cataracting one, ensuring a good balance between impact and attrition without excessive energy waste.

By understanding these fundamental factors, you gain direct control over the efficiency of your grinding process and the quality of your final product.

Summary Table:

| Factor Category | Key Variables | Impact on Grinding |

|---|---|---|

| Equipment | Mill Liners, Grinding Media (Size & Material) | Determines wear resistance and grinding mechanism (impact vs. attrition) |

| Operational Conditions | Rotational Speed (% of Critical Speed), Media Fill Ratio (30-50%) | Controls impact energy, efficiency, and final particle size |

| Material Characteristics | Feed Size, Hardness | Influences energy required and choice of media/speed |

Need to optimize your ball milling process for better efficiency and particle size control? KINTEK specializes in lab equipment and consumables, providing expert solutions for your laboratory grinding needs. Our team can help you select the right grinding media and operational parameters to achieve your specific goals. Contact us today to discuss how we can enhance your grinding performance!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the particle size of a colloid mill? Achieve 1-5 Micron Emulsions for Superior Stability

- What is the primary purpose of an ultra-centrifugal mill for Triticale Straw? Boost Your Bio-conversion Efficiency

- Can I use wet grinder for dry grinding? Avoid Damaging Your Kitchen Appliance

- Why are zirconia grinding jars and balls required for solid-state electrolyte powders? Ensure High Purity & Performance

- How does the use of grinding equipment benefit iron-substituted manganese oxide? Optimize Energy Storage Performance

- What is one of the disadvantages of ball mill method? Contamination, Slow Speed, and Inconsistent Results

- What is use for grinding in the laboratory? Select the Right Mill for Accurate Sample Prep

- What is the function of an industrial grinding mill in the pretreatment of sisal residue? Optimize Bio-Thermal Conversion