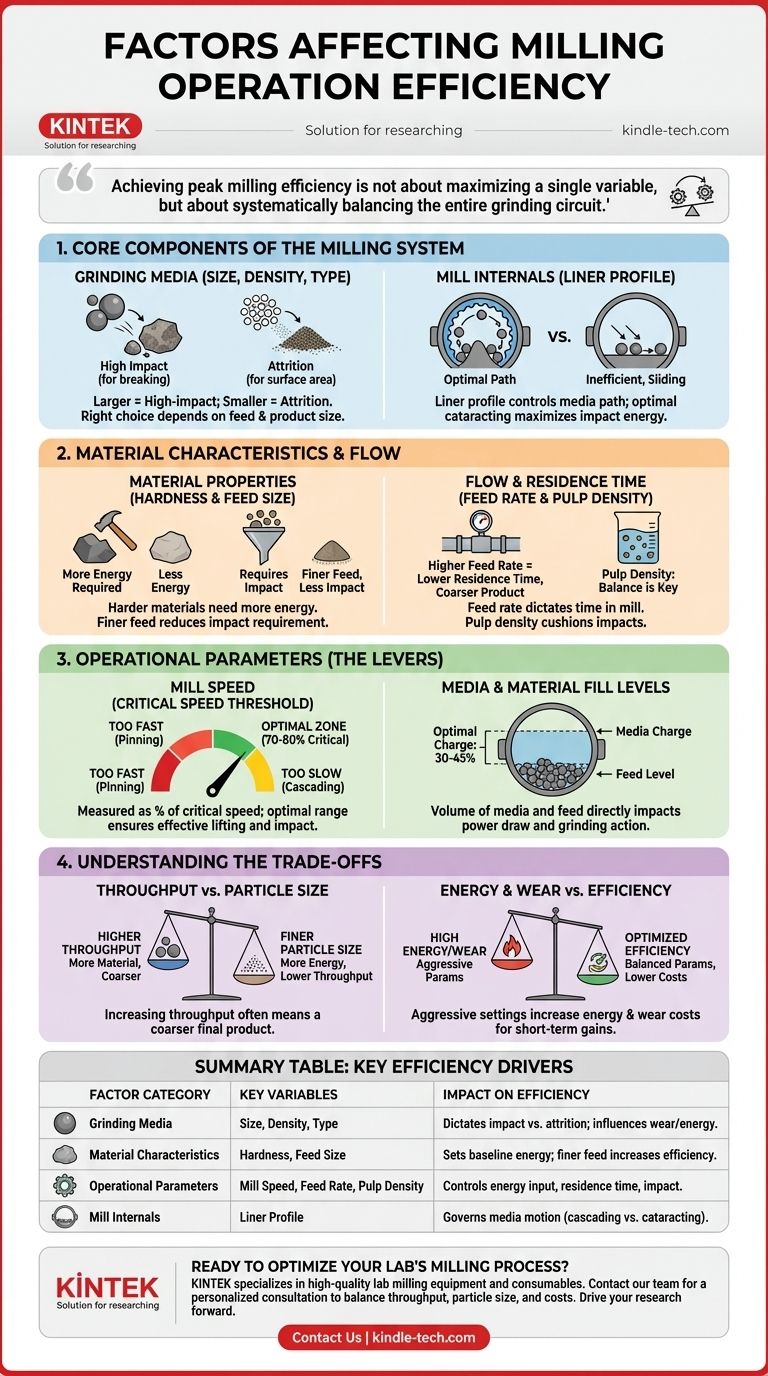

In short, milling efficiency is determined by a complex interplay between the grinding media, the characteristics of the material being processed, the mill's internal design, and the operational parameters you control. Key factors include ball size and density, mill speed, the hardness of the feed material, and the rate at which material flows through the system.

Achieving peak milling efficiency is not about maximizing a single variable, but about systematically balancing the entire grinding circuit. The goal is to match the energy input to the specific comminution requirements of your material, minimizing waste in the form of heat, noise, and unnecessary wear.

The Core Components of the Milling System

The physical setup of your mill is the foundation of its efficiency. These elements are often fixed for a given operation but are critical to understand.

Grinding Media (Size, Density, and Type)

The grinding media—typically steel or ceramic balls—are the heart of the operation. Their properties directly dictate the nature of the grinding action.

Larger, denser balls create high-impact forces, ideal for breaking down coarse feed particles. Smaller balls create more surface area and favor attrition (a rubbing or sanding action), which is more effective for producing very fine particles.

The right choice depends on your feed size and target product size. Using balls that are too large wastes energy and can cause excessive liner wear, while balls that are too small may not have enough energy to break the feed material.

Mill Internals (Liner Profile)

Liners protect the mill shell from wear and, more importantly, are designed to lift the grinding media. The profile of the liner controls how the media tumbles or cascades.

A well-designed liner profile ensures the media follows the optimal path—known as cataracting—to maximize impact energy on the material. Worn-out liners reduce lifting action, causing the media to slide, which drastically lowers grinding efficiency.

Material Characteristics and Flow

The material you are grinding and how it moves through the mill are equally important variables that define the system's overall performance.

Material Properties (Hardness and Feed Size)

The inherent properties of the material set the baseline for energy requirements. Harder materials require significantly more energy and time to break down than softer ones.

The size of the material fed into the mill is also critical. A finer feed requires less impact energy to be reduced further, allowing for the potential use of smaller media and different operational settings.

Flow and Residence Time (Feed Rate and Pulp Density)

Residence time is the amount of time material spends inside the mill. This is primarily controlled by the feed rate. A higher feed rate reduces residence time, which can increase throughput but may result in a coarser final product.

In wet grinding, pulp density (the ratio of solids to liquid) is crucial. If the pulp is too thin, the media will strike itself instead of the ore. If it is too thick, it will cushion the impacts and reduce grinding effectiveness.

Operational Parameters (The Levers You Control)

These are the dynamic variables that operators can adjust to fine-tune the milling process for optimal efficiency.

Mill Speed (The Critical Speed Threshold)

Mill speed is perhaps the most critical operational parameter. It is measured as a percentage of critical speed—the theoretical speed at which centrifugal force would pin the grinding media to the mill's inner shell.

Operating at 70-80% of critical speed typically provides the best balance, ensuring the media is lifted high enough to create powerful impacts without being flung against the liner. Running too slow causes the media to cascade down the surface, resulting in inefficient grinding.

Media and Material Fill Levels

The volume of grinding media in the mill (the media charge) directly impacts power draw and grinding action. A typical charge is between 30-45% of the mill volume.

Similarly, the feed level must be balanced. Too little material leads to wasted energy and high wear from media-on-media and media-on-liner impacts. Too much material can dampen the grinding action and reduce efficiency.

Understanding the Trade-offs

Optimizing a milling circuit is an exercise in managing competing priorities. Improving one metric often comes at the expense of another.

Throughput vs. Final Particle Size

The most common trade-off is between how much material you can process (throughput) and how fine it becomes (particle size).

Achieving a very fine grind requires more energy and a longer residence time, which inherently lowers the overall throughput of the circuit. Conversely, pushing for maximum throughput will likely result in a coarser final product.

Energy Consumption vs. Wear and Tear

Aggressive operating parameters—such as high mill speeds and the use of large, dense media—increase both energy consumption and the rate of wear on liners and the media itself.

While these settings might increase throughput in the short term, they lead to higher operational costs from increased power bills and more frequent replacement of consumable parts.

Making the Right Choice for Your Goal

Your operational strategy should align with your primary objective. There is no single "best" setting; there is only the best setting for your specific goal.

- If your primary focus is maximizing throughput: Prioritize an optimized feed rate and mill speed, but be prepared to accept a coarser grind and potentially higher wear rates.

- If your primary focus is achieving a very fine particle size: Focus on increasing residence time (lower feed rate), using smaller media for attrition, and accepting a reduction in overall throughput.

- If your primary focus is minimizing operational costs: Run at the optimal speed rather than the maximum, closely monitor liner and media wear for timely replacement, and avoid over-grinding by matching energy input to your target particle size.

Ultimately, achieving an efficient milling operation is a process of continuous, data-driven optimization across all of these interconnected factors.

Summary Table:

| Factor Category | Key Variables | Impact on Efficiency |

|---|---|---|

| Grinding Media | Size, Density, Type | Dictates impact force vs. attrition; influences wear and energy use. |

| Material Characteristics | Hardness, Feed Size | Sets baseline energy requirement; finer feed can increase efficiency. |

| Operational Parameters | Mill Speed, Feed Rate, Pulp Density | Controls energy input, residence time, and impact effectiveness. |

| Mill Internals | Liner Profile | Governs media motion (cascading vs. cataracting) for optimal impact. |

Ready to optimize your milling process and boost your lab's productivity?

KINTEK specializes in high-quality lab milling equipment and consumables. Our experts can help you select the right mill and grinding media to perfectly balance throughput, particle size, and operational costs for your specific materials and goals.

Contact our team today for a personalized consultation and discover how KINTEK's solutions can enhance your grinding efficiency and drive your research forward.

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Laboratory Single Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What are the factors affecting grinding efficiency? Optimize Your Process for Maximum Output

- What is the average speed of a ball mill? Optimize Grinding with Critical Speed Calculations

- What are the disadvantages of a ball mill? High Energy Use, Noise, and Contamination Risks

- What is the primary function of the grinding process in LiCoO2/LSPS mixtures? Optimize Solid-State Battery Conductivity

- What affects ball mill efficiency? Optimize Grinding Speed, Media, and Material for Peak Performance