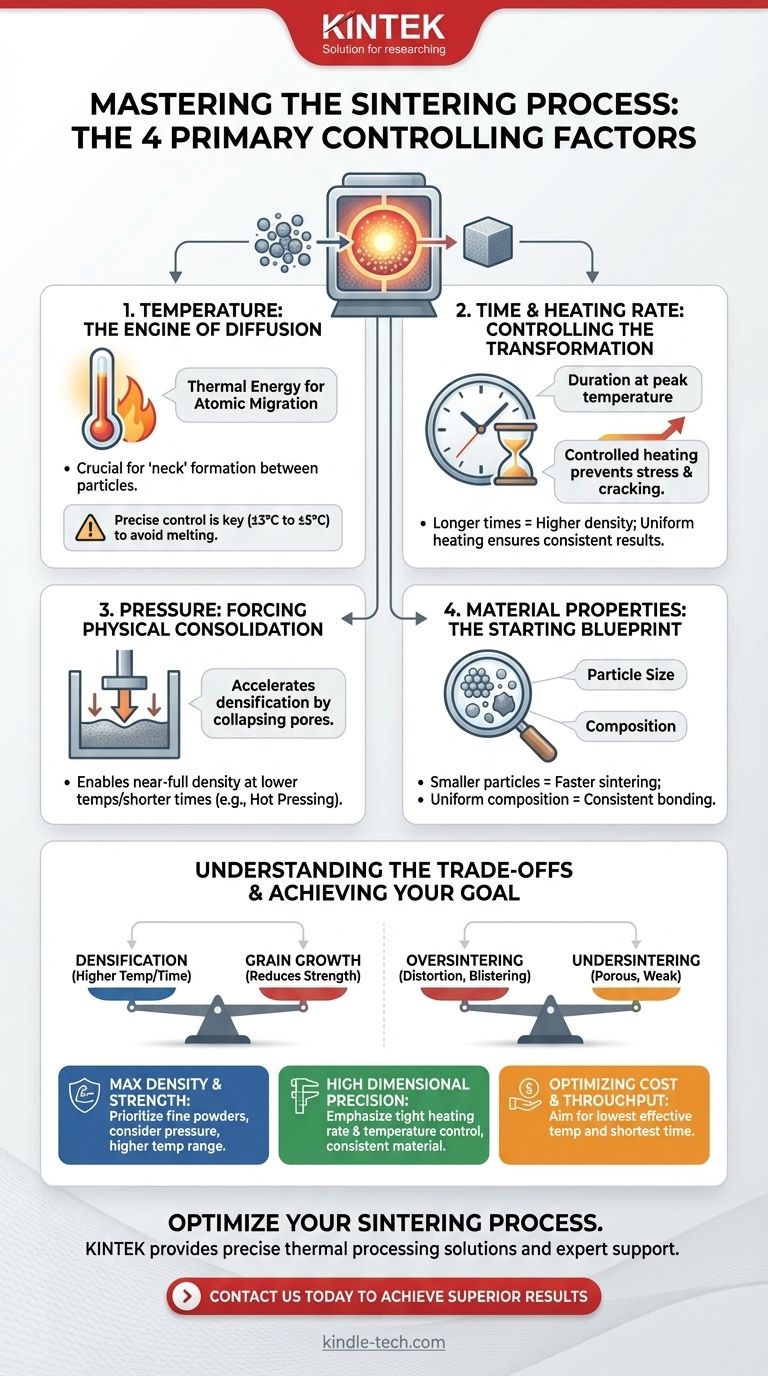

At its core, the sintering process is controlled by four primary factors: temperature, time, pressure, and the intrinsic properties of the starting material. These variables are manipulated to transform a loose powder into a dense, solid object by creating atomic bonds between particles, all without melting the bulk material. Success depends on precisely managing these factors to achieve the desired density, strength, and dimensional accuracy.

Sintering is fundamentally a process of controlled atomic diffusion. The key is to balance the process parameters to maximize inter-particle bonding and eliminate porosity, while simultaneously preventing undesirable effects like grain growth or part distortion that can compromise final performance.

The Fundamental Drivers of Sintering

To control the outcome of sintering, you must understand how each primary factor influences the material at a microscopic level. These are not independent variables; they interact to determine the final properties of the component.

Temperature: The Engine of Diffusion

Temperature is the most critical factor in sintering. It provides the thermal energy necessary for atoms to migrate across the surfaces of adjacent particles, forming metallurgical bonds or "necks" at their points of contact.

As the temperature rises, the rate of this atomic diffusion increases exponentially. However, the temperature must remain below the material's melting point. The process window is often narrow, with quality specifications frequently requiring temperature control within ±3°C to ±5°C to ensure consistent results.

Time and Heating Rate: Controlling the Transformation

Sintering time refers to the duration the material is held at the peak sintering temperature. This period allows the diffusion process, initiated by temperature, to progress and reduce the porosity between particles. Longer times generally lead to higher density.

The heating rate, or how quickly the part reaches the sintering temperature, is also crucial. A controlled rate ensures uniform heating, preventing internal stresses, cracking, or distortion, especially in larger or more complex geometries.

Pressure: Forcing Physical Consolidation

While not always required, the application of external pressure during sintering dramatically accelerates densification. Pressure enhances the process in two ways: it forces particles into a tighter arrangement, and it actively helps collapse the pores between them.

This technique, known as pressure sintering or hot pressing, can achieve near-full density at lower temperatures or in shorter times compared to pressureless (loose-powder) sintering.

Material Properties: The Starting Blueprint

The final outcome is predetermined by the characteristics of the initial powder. The two most important properties are particle size and composition.

Smaller particles possess a higher surface-area-to-volume ratio. This creates a stronger thermodynamic driving force for sintering, allowing the process to occur faster and at lower temperatures. A uniform and homogeneous composition ensures that bonding occurs consistently throughout the part, preventing weak spots.

Understanding the Trade-offs

Achieving a perfect sintered part is a balancing act. Optimizing one property often comes at the expense of another. Understanding these trade-offs is the mark of a true expert.

Densification vs. Grain Growth

The primary goal of sintering is densification—the elimination of porosity. While higher temperatures and longer times promote this, they also encourage grain growth, where smaller crystal grains merge into larger ones. Excessive grain growth can make a material more brittle and reduce its overall strength.

Oversintering vs. Undersintering

There is a precise window for optimal sintering. Undersintering occurs when temperature or time is insufficient, resulting in a porous, weak part with poor mechanical properties.

Conversely, oversintering happens when the temperature is too high or held for too long. This can lead to distortion, blistering, or even localized melting (known as "sweating"), all of which ruin the component's integrity and dimensional accuracy.

Shrinkage and Dimensional Control

As porosity is eliminated, the part inevitably shrinks. This shrinkage must be predictable and uniform to produce a component that meets tight dimensional tolerances. Non-uniform powder, inconsistent compaction, or poor temperature control can all lead to unpredictable shrinkage and warped final parts.

Making the Right Choice for Your Goal

The ideal sintering parameters are not universal; they are dictated by the specific goals for your component. Use your objective as a guide to prioritize the controlling factors.

- If your primary focus is maximum density and strength: Prioritize fine, uniform powders and consider using applied pressure. You will likely operate at the higher end of the acceptable temperature range for your material.

- If your primary focus is high dimensional precision: Emphasize extremely tight control over the heating rate and peak temperature. Consistency in your starting powder and compaction process is non-negotiable.

- If your primary focus is optimizing cost and throughput: Aim for the lowest possible temperature and shortest sintering time that reliably meets the minimum required performance specifications for the component.

Mastering sintering is about understanding how to manipulate these fundamental factors to consistently and predictably guide a powdered material to its final, functional form.

Summary Table:

| Factor | Role in Sintering | Key Consideration |

|---|---|---|

| Temperature | Drives atomic diffusion for bonding | Must remain below melting point; precise control (±3-5°C) is critical |

| Time & Heating Rate | Allows diffusion process to complete | Controlled rate prevents stress/cracking; longer times increase density |

| Pressure | Accelerates densification by forcing particle consolidation | Enables near-full density at lower temperatures/shorter times (hot pressing) |

| Material Properties | Determines the starting point for the process | Smaller particle size and uniform composition ensure consistent results |

Struggling to optimize your sintering process for maximum density, strength, or precision? KINTEK specializes in lab equipment and consumables, providing the precise thermal processing solutions and expert support your laboratory needs. Our products are designed to deliver the consistent temperature control and reliable performance required to master the critical factors of sintering. Let our experts help you achieve superior results—contact us today to discuss your specific application!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What are the advantages of vacuum sintering? Achieve Superior Purity, Strength, and Performance

- How does a vacuum environment system contribute to the hot pressing sintering of B4C-CeB6? Unlock Peak Ceramic Density

- What are the advantages of using a vacuum hot pressing sintering furnace? Superior Density for Nanocrystalline Fe3Al