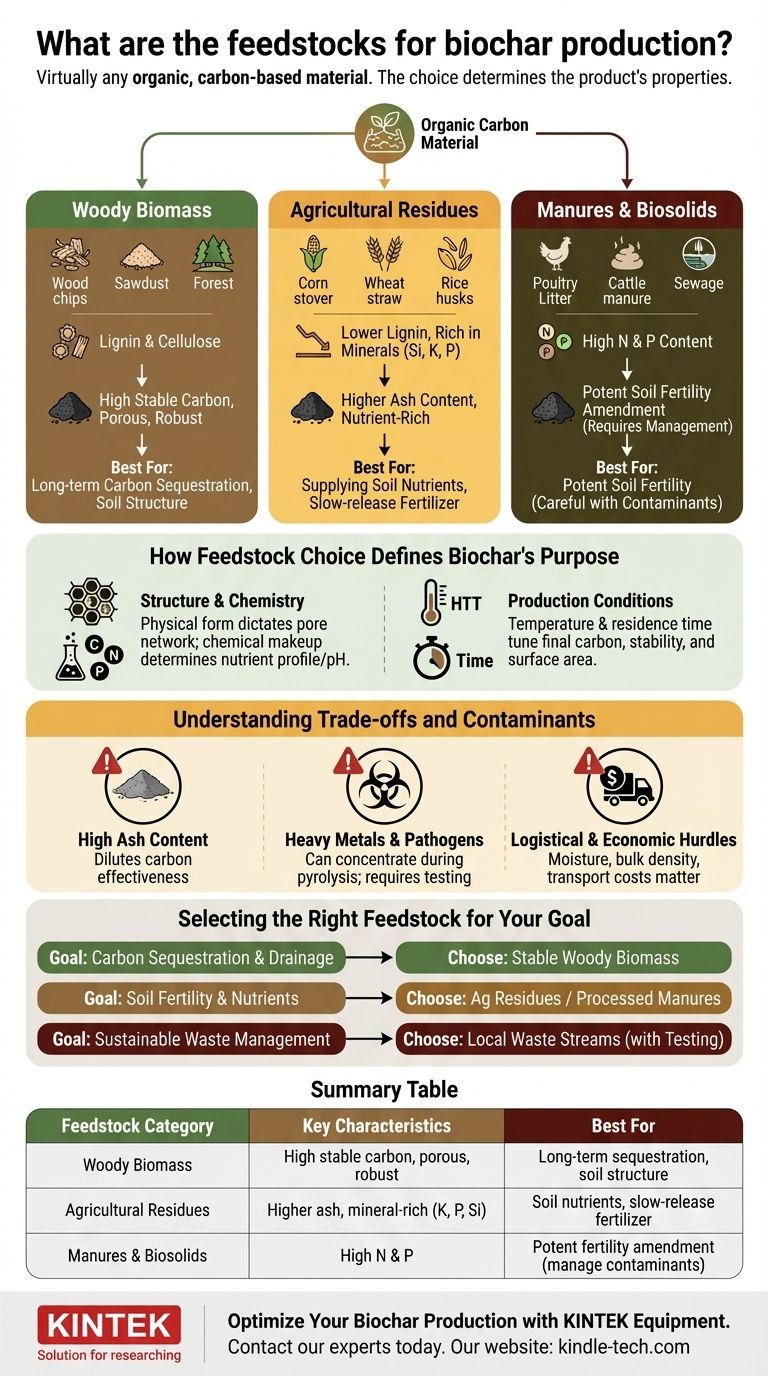

In short, virtually any form of organic, carbon-based material can serve as a feedstock for producing biochar. The most common feedstocks fall into three broad categories: woody biomass (like wood chips and forestry waste), agricultural residues (like corn stover and rice husks), and animal or municipal wastes (like manure and biosolids).

The specific feedstock you choose is the single most important decision in biochar production. It fundamentally determines the biochar's physical structure and chemical composition, which in turn dictates its suitability for applications like soil improvement or carbon sequestration.

The Three Primary Categories of Biochar Feedstock

Understanding the origin of your feedstock is the first step to predicting the qualities of your final biochar product. Each category imparts distinct characteristics.

Woody Biomass

This category includes materials like forest thinning, wood chips, sawdust, and construction wood waste. These feedstocks are high in lignin and cellulose.

Because of this composition, they typically produce a biochar that is high in stable carbon, structurally robust, and highly porous. This makes it excellent for long-term carbon sequestration and improving soil structure.

Agricultural Residues

This is a vast category that includes everything from corn stover, wheat straw, and rice husks to nutshells and fruit pits.

These materials often have lower lignin content than wood but can be rich in minerals like silica, potassium, and phosphorus. The resulting biochar tends to have a higher ash content and is often valued for its ability to supply nutrients to soil, acting as a slow-release fertilizer.

Manures and Biosolids

This group consists of animal manures (poultry litter, cattle manure) and treated municipal sewage sludge (biosolids). These feedstocks are defined by their high initial nutrient content, particularly nitrogen and phosphorus.

Biochar from these sources can be a potent soil fertility amendment. However, it requires careful management, as the feedstock can contain salts, heavy metals, or pathogens that may become concentrated during production.

How Feedstock Choice Defines Biochar's Purpose

The feedstock isn't just a raw ingredient; it's a blueprint for the final product's function. The physical and chemical properties of the source material directly translate into the biochar's performance.

The Link Between Feedstock and Structure

The physical form of the feedstock matters. Dense, fibrous materials like wood create biochar with high surface area and a network of pores. This structure is ideal for increasing water retention in sandy soils and providing a habitat for beneficial soil microbes.

The Link Between Feedstock and Chemistry

The chemical makeup of the feedstock determines the biochar's nutrient profile and pH. Feedstocks like manure or bone produce biochar rich in phosphorus, making it valuable as a fertilizer. Conversely, most wood-based biochars have a liming effect, helping to raise the pH of acidic soils.

The Role of Production Conditions

While feedstock is foundational, production conditions like Highest Treatment Temperature (HTT) and residence time are critical levers. For any given feedstock, a higher temperature generally increases the carbon content, stability, and surface area of the biochar but can vaporize some valuable nutrients like nitrogen. Adjusting these parameters allows you to fine-tune the final product for a specific goal.

Understanding the Trade-offs and Contaminants

No feedstock is perfect for every application. It's crucial to be aware of the potential downsides and logistical challenges associated with different source materials.

The Challenge of High Ash Content

Some feedstocks, especially certain agricultural residues like rice husks, are naturally high in minerals like silica. This results in a biochar with a high ash content, which is essentially non-carbon material. High ash can dilute the biochar's effectiveness for carbon sequestration and may not be desirable in all soil types.

The Risk of Heavy Metals and Pathogens

Feedstocks like biosolids or certain industrial wastes can contain heavy metals (e.g., cadmium, lead) or other contaminants. The pyrolysis process can concentrate these elements in the final biochar. Using high temperatures can destroy pathogens, but careful feedstock testing is essential to avoid contaminating soil.

Logistical and Economic Hurdles

The ideal feedstock is often the one that is most affordable and accessible. Key factors include moisture content (wet feedstock requires significant energy to dry before pyrolysis), bulk density, and transportation costs. A theoretically superior but expensive or distant feedstock is rarely a practical choice.

Selecting the Right Feedstock for Your Goal

Your intended application should guide your feedstock selection. There is no single "best" biochar, only the right biochar for the job.

- If your primary focus is long-term carbon sequestration and improving soil drainage: Choose a stable, high-carbon woody biomass feedstock that produces a porous, long-lasting biochar.

- If your primary focus is improving soil fertility and nutrient supply: Choose agricultural residues or carefully processed manures that result in a nutrient-rich, albeit less stable, biochar.

- If your primary focus is sustainable waste management: Utilize locally abundant waste streams, but invest in proper testing and processing to ensure the final product is safe and beneficial for its intended use.

Ultimately, the power of biochar lies in the deliberate selection of a feedstock to achieve a specific outcome.

Summary Table:

| Feedstock Category | Key Characteristics | Best For |

|---|---|---|

| Woody Biomass (wood chips, sawdust) | High in stable carbon, porous, robust structure | Long-term carbon sequestration, improving soil structure |

| Agricultural Residues (corn stover, rice husks) | Higher ash content, rich in minerals (K, P, Si) | Supplying soil nutrients, acting as a slow-release fertilizer |

| Manures & Biosolids (poultry litter, sewage sludge) | High in nitrogen and phosphorus | Potent soil fertility amendment (requires careful management) |

Ready to Optimize Your Biochar Production?

Your choice of feedstock is critical, but so is the equipment you use to process it. KINTEK specializes in high-quality lab equipment and pyrolysis systems designed for testing and producing biochar from a wide range of materials.

We help our customers in research, agriculture, and waste management:

- Precisely characterize different feedstocks to predict biochar yield and quality.

- Fine-tune pyrolysis parameters (temperature, residence time) to achieve your specific goals, whether for carbon sequestration or soil amendment.

- Ensure safe and efficient production, especially when working with challenging feedstocks like manures or biosolids.

Let's discuss your project. Contact our experts today to find the right solution for your biochar production needs.

Visual Guide

Related Products

People Also Ask

- What is the purpose of spark plasma sintering? Achieve Full Densification at Lower Temperatures

- What are the advantages of microwave pyrolysis? Faster, More Efficient Waste Conversion

- How plasma is generated in sputtering? The Engine Behind Thin-Film Deposition

- What are the different types of sintering process? Choose the Right Method for Your Material

- What types of plastic can be used for pyrolysis? Transform Low-Value Waste into High-Value Resources

- What industry is heat treatment? The Foundational Process Behind Aerospace, Automotive & Energy

- What are the safety issues with vacuum pumps? Avoid Chemical, Mechanical, and Implosion Risks

- What are the process variables of sintering? Master Temperature, Time, Pressure & Atmosphere