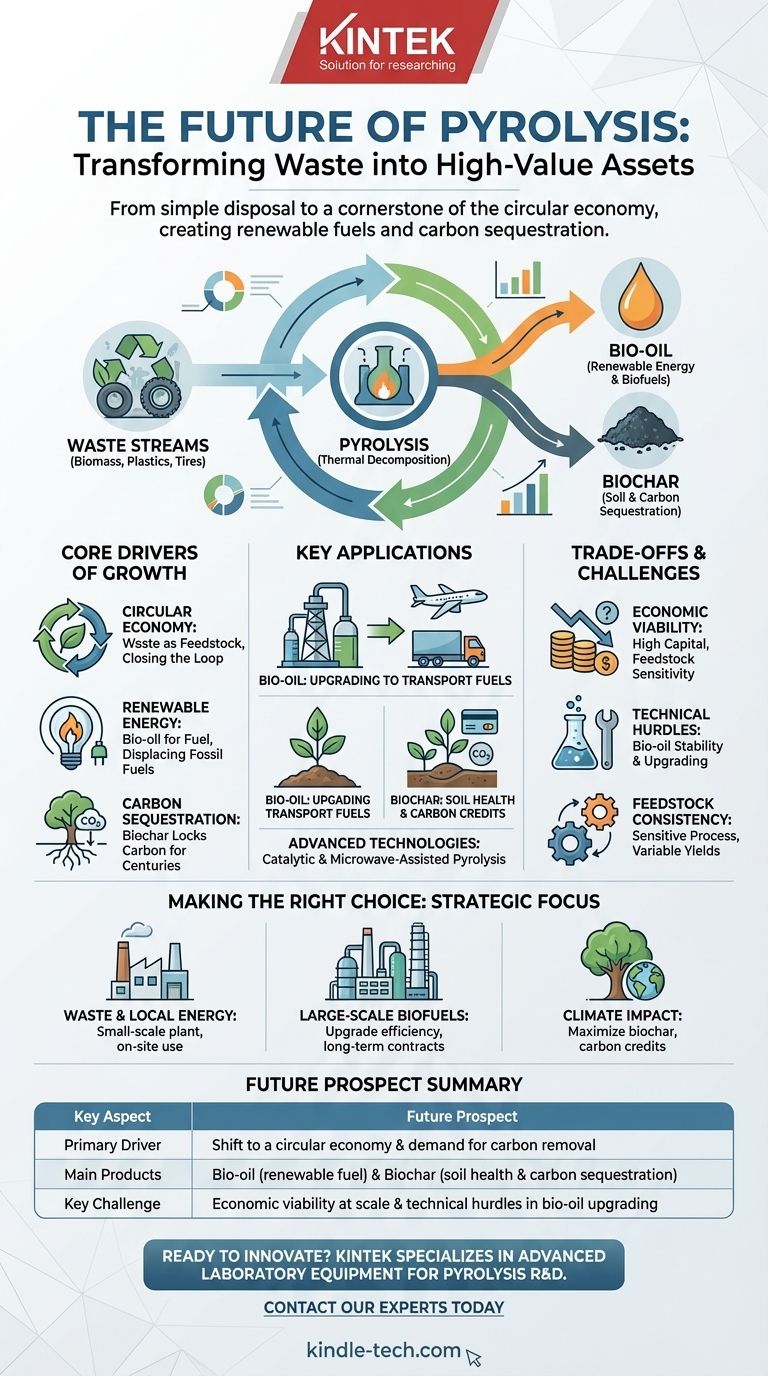

The future of pyrolysis is promising, centered on its unique ability to transform low-value waste streams into high-value products. It is evolving from a simple disposal technology into a cornerstone of the circular economy, creating renewable fuels and a powerful carbon sequestration tool. However, its widespread adoption hinges on overcoming key economic and technical challenges related to scale and product refinement.

Pyrolysis is no longer just about managing waste; it is about valorizing it. Its future lies in converting biomass and plastics into two key outputs: bio-oil for renewable energy and biochar for agricultural and environmental applications, creating a powerful loop for a sustainable economy.

The Core Drivers of Pyrolysis Growth

The momentum behind pyrolysis is driven by major global shifts in how we view waste, energy, and carbon. It directly addresses the need to move from a linear "take-make-dispose" model to a circular one.

The Shift to a Circular Economy

Traditionally, waste like agricultural residue, forestry byproducts, and end-of-life plastics were seen as disposal problems. Pyrolysis reframes them as feedstocks. By thermally decomposing this material in the absence of oxygen, it creates valuable new substances, closing the loop and reducing landfill dependence.

Demand for Renewable Energy Sources

Bio-oil, the liquid product of pyrolysis, can be used to generate heat and power. More importantly, it can be upgraded into advanced biofuels, such as renewable diesel and sustainable aviation fuel. This provides a direct pathway to displace fossil fuels in sectors that are difficult to electrify, like heavy transport and aviation.

The Need for Carbon Sequestration

Biochar, the solid, charcoal-like co-product, is a stable form of carbon. When used as a soil amendment, it not only improves soil health and water retention but also locks carbon in the ground for centuries. This makes it one of the most promising and scalable methods for long-term carbon dioxide removal.

Key Applications Shaping the Future

The prospects of pyrolysis are defined by the viability of its end products. Innovation is focused on improving the quality and consistency of both bio-oil and biochar to meet market demands.

Bio-oil as a Fuel and Chemical Precursor

Raw bio-oil can be burned in industrial boilers and furnaces for energy. The greater opportunity, however, is in upgrading it into transportation fuels. This "upgrading" process is a major area of research, as it stabilizes the oil and makes it compatible with existing refinery infrastructure.

Biochar for Agriculture and Remediation

Biochar's porous structure makes it an excellent soil amendment, increasing fertility and reducing the need for chemical fertilizers. Its ability to sequester carbon is also gaining significant attention in carbon credit markets, creating a new revenue stream for pyrolysis operations.

Advanced Pyrolysis Technologies

The industry is moving beyond basic pyrolysis. Catalytic pyrolysis uses catalysts to directly influence the chemical reactions, producing a higher-quality bio-oil that requires less post-processing. Technologies like microwave-assisted pyrolysis are also being explored to improve energy efficiency and control.

Understanding the Trade-offs and Challenges

Despite its potential, pyrolysis is not a silver bullet. Understanding its limitations is crucial for realistic and successful implementation.

Economic Viability and Scale

Pyrolysis plants require significant upfront capital investment. Their profitability is highly sensitive to the cost and availability of feedstock. A consistent, low-cost supply of waste material within a reasonable transport distance is essential for a project to be economically viable.

Technical Hurdles in Bio-oil Upgrading

Raw bio-oil is acidic, corrosive, and unstable, making it difficult to transport and use directly in conventional engines or refineries. The process of upgrading it to a stable, transport-grade fuel adds significant cost and complexity to the overall operation. This is a primary barrier to its widespread use as a "drop-in" fuel.

Feedstock Consistency

Pyrolysis is a sensitive process, and its efficiency and product yields are heavily dependent on the type and quality of the feedstock. Variations in moisture content, chemical composition, and physical size of materials like wood, plastics, or tires require constant process adjustments, complicating operations at scale.

Making the Right Choice for Your Goal

The viability of a pyrolysis project depends entirely on its primary objective. Defining your goal is the first step toward a successful strategy.

- If your primary focus is waste management and local energy: A smaller-scale plant using local agricultural or municipal waste to produce bio-oil for on-site heat and power can be highly effective and profitable.

- If your primary focus is large-scale biofuel production: Success depends on securing technology that efficiently upgrades bio-oil and establishing long-term contracts for both feedstock supply and fuel offtake with refineries or transport companies.

- If your primary focus is climate impact and carbon removal: Prioritize systems that maximize high-quality biochar production and secure its offtake through agricultural partners or by participating in formal carbon credit markets.

Ultimately, the future of pyrolysis is secured by its unique capacity to solve multiple problems at once, turning environmental liabilities into economic and ecological assets.

Summary Table:

| Key Aspect | Future Prospect |

|---|---|

| Primary Driver | Shift to a circular economy and demand for carbon removal. |

| Main Products | Bio-oil (for renewable fuel) and Biochar (for soil health & carbon sequestration). |

| Key Challenge | Economic viability at scale and technical hurdles in bio-oil upgrading. |

Ready to integrate pyrolysis technology into your sustainability or waste management strategy? KINTEK specializes in supplying advanced laboratory equipment for pyrolysis research and development. Whether you are exploring feedstock viability, optimizing bio-oil yields, or characterizing biochar, our tools are designed to support your innovation. Contact our experts today to discuss how our solutions can accelerate your project and help you capitalize on the future of pyrolysis.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas