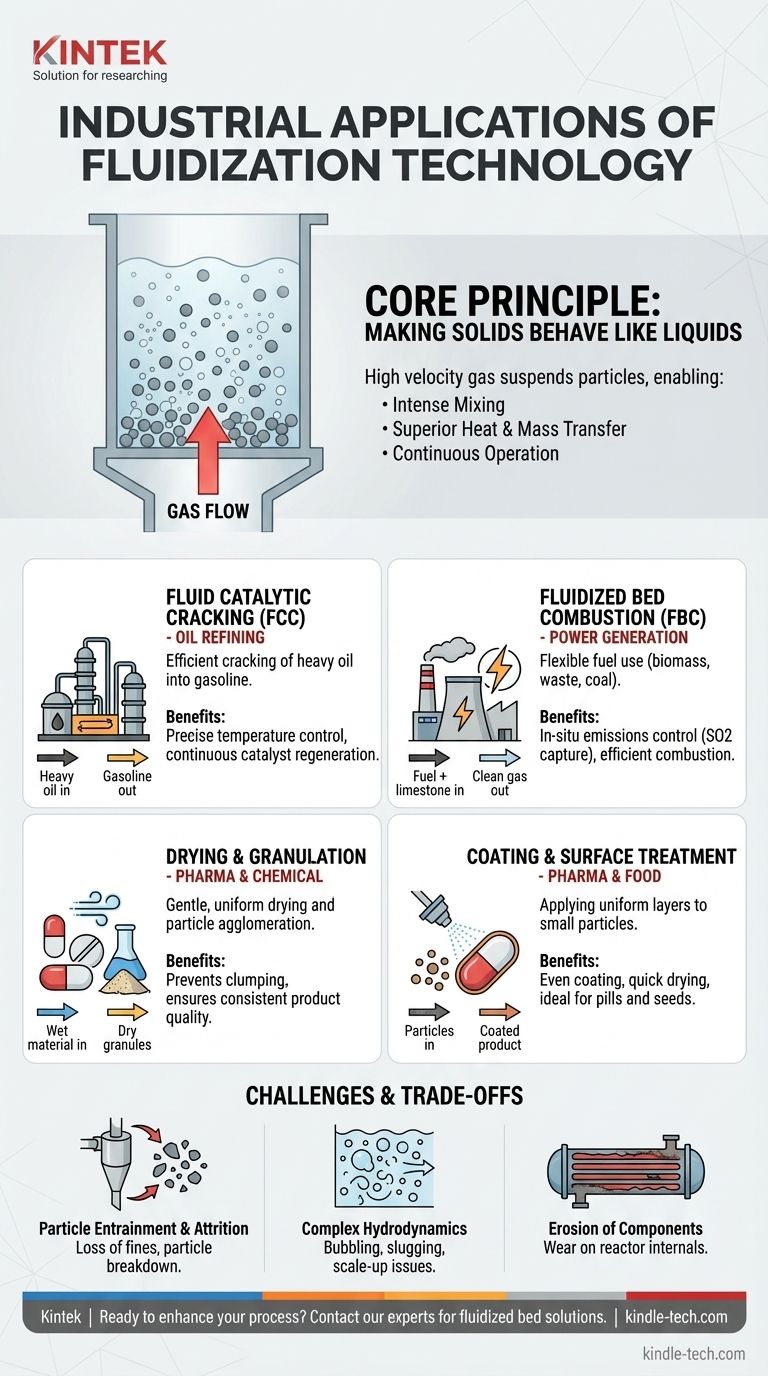

In industrial processes, fluidization is a cornerstone technology used to make a bed of solid particles behave like a fluid. Its applications are vast, but it is most prominently used for fluid catalytic cracking (FCC) in oil refineries, fluidized bed combustion (FBC) for power generation, bulk solids drying in the chemical and pharmaceutical industries, and particle coating. These processes all leverage the unique properties of a fluidized state to achieve superior performance.

The core value of fluidization is its ability to create exceptionally high rates of heat and mass transfer between a gas and solid particles. This liquid-like behavior ensures uniform temperatures and efficient mixing, making it the ideal choice for large-scale, heat-intensive chemical reactions and physical treatments.

The Fundamental Advantage: Making Solids Behave Like Liquids

To understand its applications, you must first grasp why making solids act like a fluid is so powerful. This is achieved by passing a gas or liquid upward through a bed of particles at a velocity high enough to suspend them.

The Benefit of Intense Mixing

In a fluidized bed, the solid particles are in constant, chaotic motion. This intense mixing is similar to that of a boiling liquid.

This action eliminates temperature gradients and concentration differences within the bed. As a result, hot spots are prevented in highly exothermic reactions, which could otherwise lead to catalyst deactivation or dangerous runaway conditions.

Superior Heat and Mass Transfer

The primary engineering advantage of fluidization is the dramatic enhancement of transfer rates. The immense surface area of the suspended particles, combined with the turbulent mixing, ensures that heat and reactants are transferred between the fluid and the solids almost instantaneously.

This makes processes far more efficient than in a static or packed bed, where transfer is limited by slow diffusion.

Continuous Operation and Solids Handling

Because the solids behave like a fluid, they can be easily and continuously transported. Particles can be fed into and withdrawn from the reactor vessel using simple pipes and valves, just as if they were a liquid.

This capability is critical for processes that require constant catalyst regeneration, such as Fluid Catalytic Cracking (FCC).

Key Industrial Applications in Detail

The unique advantages of fluidization make it the preferred technology in several major industries. Each application directly exploits one or more of its core benefits.

Fluid Catalytic Cracking (FCC) in Oil Refining

This is the most significant large-scale application. FCC units "crack" heavy, low-value crude oil fractions into more valuable products like gasoline.

The process is highly endothermic and requires precise temperature control, which the fluidized bed provides. The tiny catalyst particles are continuously circulated between a reactor and a regenerator, a feat made possible by their fluid-like handling.

Fluidized Bed Combustion (FBC) for Power Generation

FBC boilers are known for their fuel flexibility. The excellent mixing and heat transfer allow them to efficiently burn low-grade fuels like high-sulfur coal, biomass, or industrial waste.

A key benefit is in-situ emissions control. By adding limestone directly into the fluidized bed, sulfur dioxide (a primary cause of acid rain) is captured as solid calcium sulfate, eliminating the need for expensive downstream scrubbers.

Drying and Granulation

In the pharmaceutical, food, and chemical industries, fluidized beds are used to gently and uniformly dry granular materials and powders. The constant motion prevents clumping and ensures every particle is exposed to the drying gas.

The same principle is used for granulation, where fine powders are agglomerated into larger, more manageable granules by spraying a liquid binder into the fluidized bed.

Coating and Surface Treatment

Fluidized bed coating is essential for applying uniform layers to small particles, most famously in the pharmaceutical industry for coating pills.

The particles are suspended in a stream of hot air while a coating solution is sprayed onto them. The chaotic movement ensures the entire surface of each particle is evenly coated and dried.

Understanding the Trade-offs and Challenges

Despite its advantages, fluidization is not a universal solution. It presents unique engineering challenges that must be managed.

Particle Entrainment and Attrition

The upward flow of gas can carry fine particles out of the reactor, a phenomenon known as entrainment. This requires the use of downstream cyclones or filters to capture and return the solids, adding complexity and cost.

Furthermore, the constant collisions between particles can cause them to break down, a process called attrition. This generates more fines, exacerbating the entrainment problem.

Complex Hydrodynamics

The behavior of a fluidized bed is complex and can be difficult to predict. Issues like bubbling, slugging (where large gas bubbles form), and channeling (where the gas bypasses the solids) can lead to poor contacting and reduced efficiency.

Scaling up a fluidized bed from a lab-scale model to an industrial-scale unit is a significant engineering challenge due to these complex hydrodynamics.

Erosion of Components

The moving, abrasive particles can cause significant wear and tear on the internal components of the reactor, such as heat exchanger tubes and gas distributors. This necessitates the use of erosion-resistant materials and designs, increasing maintenance and capital costs.

Making the Right Choice for Your Process

Deciding whether to use a fluidized bed requires balancing its powerful benefits against its operational complexities.

- If your primary focus is maximizing reaction rates and temperature control: Fluidization is ideal for highly exothermic or endothermic reactions where preventing hot spots is critical.

- If your primary focus is processing difficult or low-grade solid fuels: Fluidized bed combustion offers unmatched flexibility and integrated emission control for burning materials like biomass, waste, or lignite.

- If your primary focus is producing uniform, high-quality particles: Fluidized beds are the industry standard for gentle drying, effective granulation, and uniform coating.

- If your primary focus is operational simplicity and low capital cost: You must carefully evaluate if the benefits outweigh the challenges of particle loss, erosion, and complex fluid dynamics.

By understanding its core principles and inherent trade-offs, you can determine if fluidization is the powerful solution your industrial process requires.

Summary Table:

| Application | Key Industry | Primary Benefit |

|---|---|---|

| Fluid Catalytic Cracking (FCC) | Oil Refining | Efficient cracking of heavy oil fractions |

| Fluidized Bed Combustion (FBC) | Power Generation | Fuel flexibility & in-situ emissions control |

| Drying & Granulation | Pharmaceutical/Chemical | Uniform drying & particle agglomeration |

| Coating & Surface Treatment | Pharmaceutical/Food | Even coating of pills and particles |

Ready to enhance your industrial process with fluidization technology? KINTEK specializes in advanced lab equipment and consumables for developing and scaling fluidized bed processes. Whether you're in R&D or production, our expertise ensures efficient heat transfer, uniform mixing, and superior particle handling. Contact our experts today to discuss how we can support your laboratory and industrial needs!

Visual Guide

Related Products

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- High Performance Laboratory Freeze Dryer

People Also Ask

- What makes activated carbon activated? The Process That Creates a Molecular Sponge

- What is the calcining zone in the kiln? The Key to Efficient Chemical Transformation

- What are the requirements for activated carbon? Matching Properties to Your Application for Success

- What is the production of biochar through pyrolysis? Optimize for Soil Health & Carbon Sequestration

- What does calcination remove? A Guide to Thermal Decomposition for Material Processing

- What are the different types of rotary kiln incinerators? Find the Right Design for Your Waste Stream

- What is sintering process in steel industry? The Essential Bridge to Efficient Ironmaking

- What are the essential features of the fast pyrolysis process? Maximize Bio-Oil Yield from Biomass