At their core, Ultra-Low Temperature (ULT) freezers are defined by their ability to reliably maintain temperatures between -40°C and -86°C. They achieve this through a combination of powerful, specialized cooling mechanisms, advanced insulation, and comprehensive monitoring systems designed to protect high-value biological samples.

A ULT freezer is not just a colder version of a standard freezer. It is an integrated system where every feature—from the compressor technology to the alarm notifications—works in concert to provide one critical outcome: absolute confidence in long-term sample integrity.

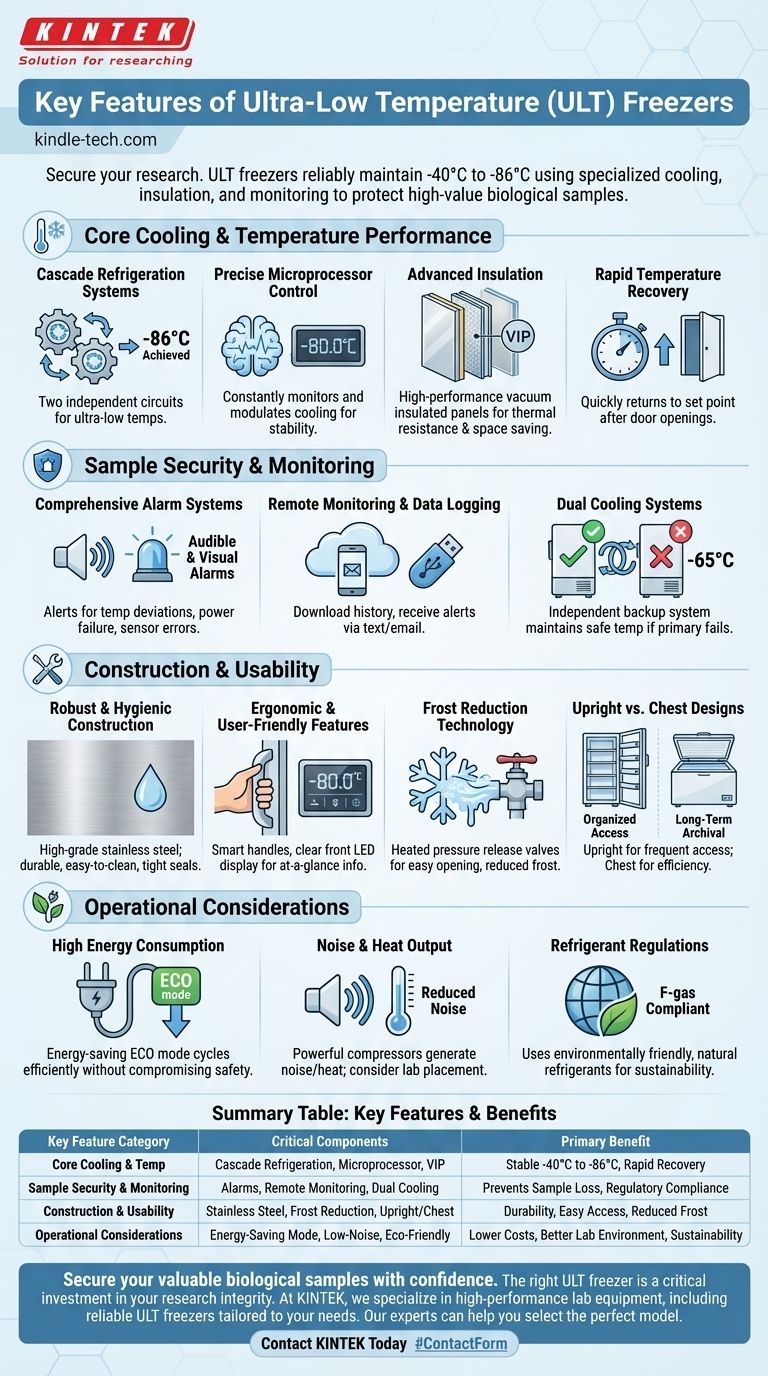

Core Cooling and Temperature Performance

The primary function of a ULT freezer is to create and sustain an extremely cold and stable environment. The features that enable this are the most critical differentiators from conventional cooling units.

Cascade Refrigeration Systems

This is the workhorse technology of most ULT freezers. Instead of a single compressor, a cascade system uses two independent refrigeration circuits. The first circuit cools the second, allowing the second circuit to reach the ultra-low temperatures required.

Precise Microprocessor Control

Modern ULT freezers are managed by a microprocessor-based controller. This digital brain constantly monitors internal conditions and precisely modulates the cooling system to maintain the temperature set point with minimal fluctuation.

Advanced Insulation

To maintain efficiency at such extreme temperatures, ULT freezers use high-performance insulation, often vacuum insulated panels (VIPs). This provides maximum thermal resistance without requiring excessively thick walls, thus saving valuable laboratory floor space.

Rapid Temperature Recovery

Every time the door is opened, warm air enters. A key performance feature is quick temperature pull-down and recovery. Powerful compressors and smart system design ensure the freezer rapidly returns to its set point, minimizing the risk to samples.

Sample Security and Monitoring

Protecting valuable, often irreplaceable, samples is the ultimate goal. ULT freezers incorporate multiple layers of security and monitoring to prevent loss.

Comprehensive Alarm Systems

Nearly all units feature audible and visual alarms to alert users of any deviations from the set parameters. This includes high/low temperature warnings, power failure alerts, and sensor errors.

Remote Monitoring and Data Logging

Many freezers are equipped with ports (like USB) for downloading temperature history, which is essential for regulatory compliance and quality assurance. More advanced systems can be integrated with external monitoring services to send remote alerts via text or email in case of a failure.

Dual Cooling Systems

For the highest level of security, some premium models offer dual cooling systems. These are essentially two independent freezers in one cabinet. If one system fails, the other can maintain a safe temperature (around -65°C to -70°C), providing crucial time to save samples.

Construction and Usability

The physical design of a ULT freezer impacts its day-to-day usability, longevity, and effectiveness in a busy lab environment.

Robust and Hygienic Construction

Interiors are typically made of high-grade stainless steel, which is durable, corrosion-resistant, and easy to clean. Tightly sealed doors with multiple gaskets are critical for preventing temperature loss.

Ergonomic and User-Friendly Features

Modern designs include features like ergonomic smart handles that are easy to open and close. A clear, front-mounted LED display provides at-a-glance information on internal temperature, set points, and alarm status.

Frost Reduction Technology

Frost buildup is a persistent issue that can impact door seals and temperature stability. Features like heated pressure release valves make the door easier to open after closing and help minimize the accumulation of frost and ice.

Upright vs. Chest Designs

ULT freezers come in two primary configurations. Upright freezers offer easy, organized access to frequently used samples, much like a refrigerator. Chest freezers are better suited for long-term archival storage, as they lose less cold air when opened.

Understanding the Trade-offs

While essential, ULT freezers come with operational considerations that require careful management.

High Energy Consumption

Maintaining -86°C requires a significant amount of energy. To mitigate this, many modern units feature an energy-saving or "ECO" mode, which cycles the compressors more efficiently without compromising sample safety, often raising the set point slightly to -70°C.

Noise and Heat Output

The powerful compressors generate considerable noise and heat. Manufacturers are increasingly focused on reduced noise level technology, but placement within the lab remains an important consideration to ensure a comfortable work environment.

Refrigerant Regulations

Environmental regulations, like F-gas conformity in Europe, are phasing out older refrigerants with high global warming potential. Newer models use natural, environmentally friendly refrigerants, which is a key factor for sustainability goals.

Making the Right Choice for Your Goal

Selecting the right features depends entirely on your specific application and priorities.

- If your primary focus is maximum sample security: Prioritize a model with a dual cooling system, comprehensive remote alarms, and rapid temperature recovery performance.

- If your primary focus is long-term archival storage: A chest freezer may offer superior temperature stability and efficiency for samples that are rarely accessed.

- If your primary focus is operational efficiency and lab environment: Look for features like an energy-saving mode, low-noise design, and modern, F-gas compliant refrigerants.

Ultimately, a ULT freezer is a long-term investment in the security of your research.

Summary Table:

| Key Feature Category | Critical Components | Primary Benefit |

|---|---|---|

| Core Cooling & Temperature | Cascade Refrigeration, Microprocessor Control, VIP Insulation | Stable -40°C to -86°C environment, rapid recovery |

| Sample Security & Monitoring | Comprehensive Alarms, Remote Monitoring, Dual Cooling Systems | Prevents sample loss, ensures regulatory compliance |

| Construction & Usability | Stainless Steel Interior, Frost Reduction, Upright/Chest Designs | Durability, easy access, reduced frost buildup |

| Operational Considerations | Energy-Saving Mode, Low-Noise Design, Eco-Friendly Refrigerants | Lower operating costs, better lab environment, sustainability |

Secure your valuable biological samples with confidence. The right ULT freezer is a critical investment in your research integrity. At KINTEK, we specialize in providing high-performance lab equipment, including reliable ULT freezers tailored to your specific laboratory needs. Our experts can help you select a model with the perfect balance of sample security, energy efficiency, and usability. Contact us today to ensure your samples are protected for the long term. Get in touch with our lab equipment specialists now!

Visual Guide

Related Products

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs