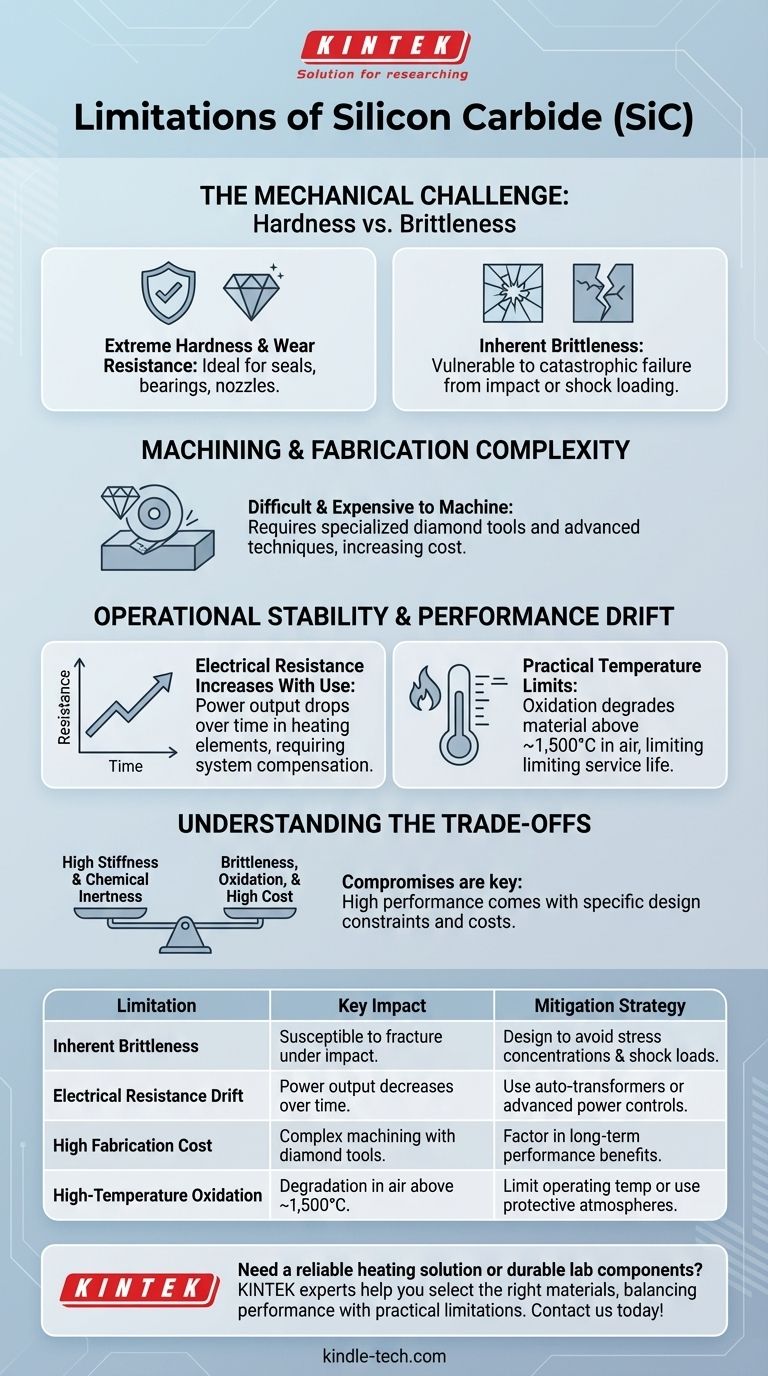

Despite its exceptional capabilities, silicon carbide (SiC) is not without practical limitations. Its primary drawbacks are its inherent brittleness, which makes it susceptible to fracture under impact, and a tendency for its electrical resistance to increase over time when used as a heating element, requiring compensatory control systems.

While silicon carbide offers superior hardness, high-temperature stability, and chemical resistance, its core limitation is a trade-off: the very properties that make it strong also make it brittle and more complex to manage in real-world applications compared to traditional metals.

The Mechanical Challenge: Hardness vs. Brittleness

Silicon carbide's mechanical properties are its most defining feature, but they present a significant design challenge. It behaves very differently from metals under stress.

Extreme Hardness and Wear Resistance

SiC is one of the hardest commercially available materials, which gives it outstanding resistance to abrasion and wear. This makes it ideal for components like seals, bearings, and nozzles.

Inherent Brittleness

Unlike metals that bend or deform under high stress, SiC fractures. This brittleness means it has very low toughness and is vulnerable to catastrophic failure from sudden impact, shock loading, or stress concentrations.

Machining and Fabrication Complexity

The extreme hardness that makes SiC so durable also makes it very difficult and expensive to machine. Standard cutting tools are ineffective, requiring specialized diamond grinding and advanced processing techniques, which adds significant cost and complexity to manufacturing finished parts.

Operational Stability and Performance Drift

For applications that leverage its thermal and electrical properties, SiC's performance can change over its operational life, a factor that must be managed.

Electrical Resistance Increases With Use

When used to create heating elements or resistors, the electrical resistance of SiC gradually increases with operational hours. This phenomenon is a well-known aspect of its aging process.

The Need for System Compensation

This resistance drift means that a constant voltage will deliver progressively less power and heat over time. To maintain stable performance, systems often require an auto-transformer or a more sophisticated power controller to increase the voltage and compensate for the material's changing resistance.

Practical Temperature Limits

While SiC performs well at high temperatures, its use in air is generally limited to around 1,500°C. Above this temperature, oxidation can begin to degrade the material, limiting its effective service life.

Understanding the Trade-offs

Choosing silicon carbide requires a clear understanding of its inherent compromises. Its strengths and weaknesses are two sides of the same coin.

The Paradox of High Stiffness

SiC has a very high stiffness and a low coefficient of thermal expansion, meaning it holds its shape exceptionally well under thermal and mechanical loads. However, this same rigidity prevents it from flexing to absorb energy, contributing directly to its brittleness.

Chemical Inertness vs. High-Temp Oxidation

SiC exhibits excellent chemical stability and is highly resistant to strong acids. This inertness does not extend to high-temperature reactions with oxygen in the air, which defines its practical upper temperature ceiling in many applications.

Performance vs. Cost

The superior performance of SiC in harsh environments comes at a price. The raw material processing and the complex fabrication required make SiC components significantly more expensive than those made from conventional metals or other ceramics.

Making the Right Choice for Your Application

To use silicon carbide effectively, you must design your system specifically around its limitations rather than treating it as a simple drop-in replacement for other materials.

- If your primary focus is wear resistance in a structural part: SiC is an excellent choice, but you must design the component and its housing to mitigate any risk of impact or shock loading.

- If your primary focus is high-temperature electrical heating: Plan to implement a control system that can actively compensate for the gradual increase in resistance to ensure stable, long-term performance.

- If your primary focus is component stability at high temperatures: SiC's low thermal expansion is a major advantage, but you must account for its higher manufacturing cost and the complexities of machining it into your desired shape.

Understanding these constraints is the key to successfully leveraging silicon carbide's remarkable strengths in your application.

Summary Table:

| Limitation | Key Impact | Mitigation Strategy |

|---|---|---|

| Inherent Brittleness | Susceptible to fracture under impact or shock | Design to avoid stress concentrations and impact loads |

| Electrical Resistance Drift | Power output decreases over time; requires compensation | Use auto-transformers or advanced power control systems |

| High Fabrication Cost | Complex and expensive machining with diamond tools | Factor in higher initial cost versus long-term performance benefits |

| High-Temperature Oxidation | Degradation in air above ~1,500°C | Limit operating temperature or use protective atmospheres |

Need a reliable heating solution or durable lab components? KINTEK specializes in high-performance lab equipment and consumables. Let our experts help you select the right materials for your specific application, balancing performance with practical limitations. Contact us today to discuss how we can support your laboratory's needs with tailored solutions!

Visual Guide

Related Products

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

People Also Ask

- Why use high-precision ceramic crevice formers in corrosion testing? Ensure Accuracy in Metallic Alloy Research

- How to decrease porosity in aluminum oxide? Master Powder & Sintering for Maximum Density

- What is the most drawbacks of zirconia based material? The Hidden Risks of Its Extreme Hardness

- Why is sintering important in ceramic processing? Achieve Dense, High-Performance Ceramic Parts

- What is the process of sintering in ceramic materials? A Guide to Transforming Powder into High-Strength Parts

- How does grain size affect the properties of ceramics? Master Hardness vs. Toughness for Your Application

- What is the relationship between sintering temperature and melting temperature? Key Differences for Material Engineers

- Are there any disadvantages of ceramics? The Trade-Off Between Hardness and Brittleness