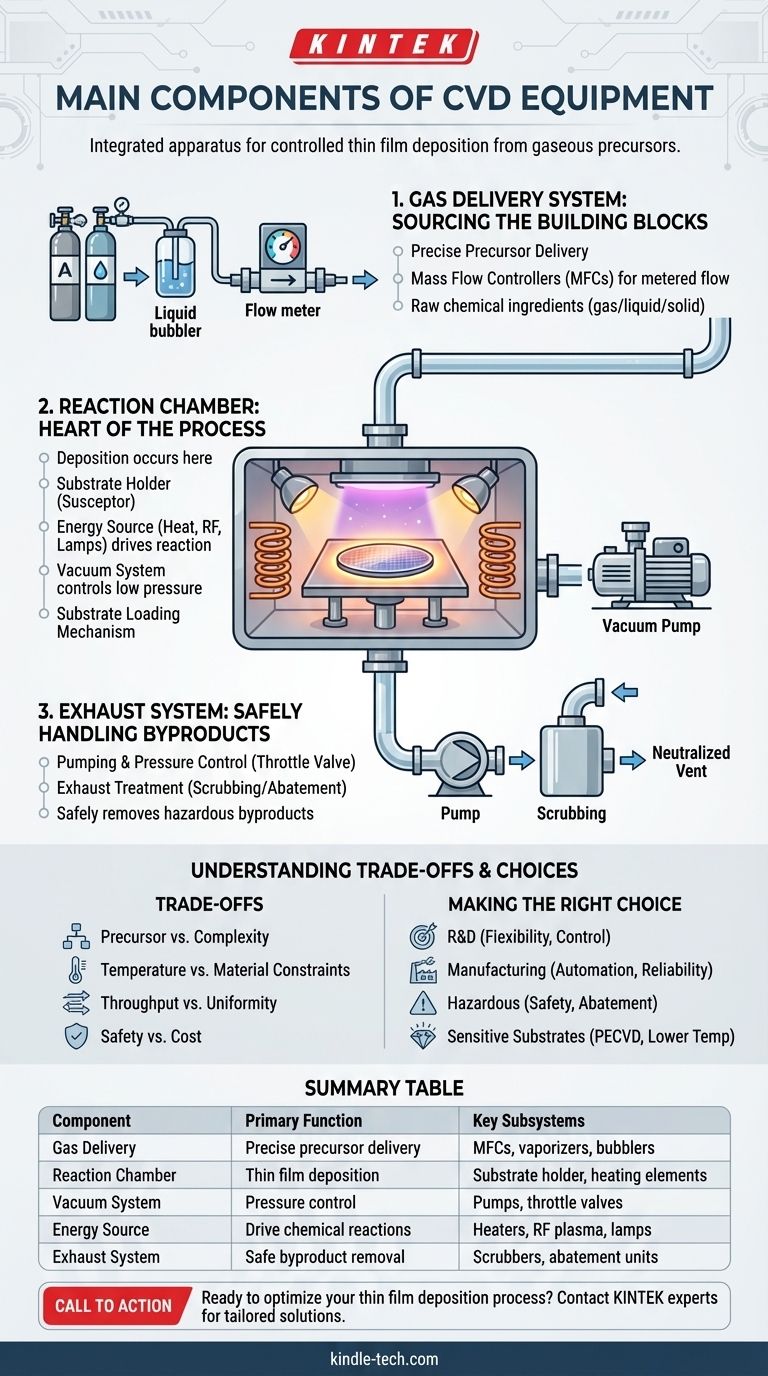

At its core, a Chemical Vapor Deposition (CVD) system is an integrated apparatus designed to create a highly controlled environment for depositing a solid thin film onto a substrate from gaseous precursors. The main components are a gas delivery system to supply the chemical reactants, a reaction chamber where the deposition occurs, an energy source to drive the reaction, a vacuum system to control the pressure, and an exhaust system to safely remove byproducts.

A CVD system is not merely a collection of parts, but a complete process flow. It can be understood as three fundamental stages: introducing precise amounts of chemical precursors, creating a specific reaction environment on a substrate, and safely managing the resulting exhaust.

The Gas Delivery System: Sourcing the Building Blocks

The entire CVD process begins with the precise delivery of precursor materials into the reactor. The quality and uniformity of the final film are directly dependent on the accuracy and stability of this system.

Precursor Sources and Delivery

Precursors are the raw chemical ingredients that will react to form the film. They can be gases, volatile liquids, or even solids that are sublimated or vaporized. The delivery system is designed to handle the specific state of the chosen precursor.

Mass Flow Controllers (MFCs)

To ensure a repeatable process, the flow of each gas must be precisely metered. Mass Flow Controllers (MFCs) are critical devices that measure and control the flow rate of gases into the chamber, regardless of fluctuations in pressure.

The Reaction Chamber: The Heart of the Process

The reaction chamber, or reactor, is the central component where all the critical steps of deposition take place. Its design is paramount to achieving the desired film properties.

The Chamber and Substrate Holder

The chamber itself is a sealed vessel, often made of quartz or stainless steel, that contains the reaction. Inside, a substrate holder (also called a susceptor) holds the material to be coated, which is known as the substrate. The holder often plays a role in heating the substrate.

The Energy Source

CVD processes require energy to decompose the precursor gases and drive the chemical reactions. This energy is typically supplied as heat from sources like resistive heating elements, RF induction coils, or high-intensity lamps.

The Substrate Loading Mechanism

For a system to be practical, there must be a way to insert and remove substrates without compromising the chamber's controlled environment. This can range from a simple manual load-lock door to a fully automated robotic wafer handling system in production environments.

The Vacuum System

Most CVD processes operate at pressures far below atmospheric levels. A vacuum system, consisting of one or more pumps, is used to evacuate the chamber initially and to maintain the specific low pressure required for the deposition process.

The Exhaust System: Safely Handling Byproducts

The chemical reactions in CVD are often incomplete and produce volatile byproducts, some of which can be hazardous or environmentally harmful. The exhaust system manages this waste stream.

Pumping and Pressure Control

In concert with the gas delivery system, the exhaust pumps maintain the correct pressure inside the reactor. A throttle valve is often placed before the pumps to provide dynamic control over the chamber pressure.

Exhaust Treatment (Scrubbing)

Before waste gases can be vented to the atmosphere, they must be treated. An exhaust gas treatment system, often called a scrubber or abatement unit, neutralizes, burns, or otherwise renders the harmful byproducts safe.

Understanding the Trade-offs

The components of a CVD system are deeply interconnected, and the design of one part has significant implications for the others. There is no single "best" configuration; the optimal setup is always a series of trade-offs based on the specific application.

Precursor Choice vs. System Complexity

Using a stable, gaseous precursor simplifies the gas delivery system significantly. In contrast, using less-volatile liquid or solid precursors requires additional hardware like bubblers or vaporizers, which adds complexity and potential points of failure.

Temperature vs. Material Constraints

High-temperature processes (often >1000°C) can produce very high-quality films but place extreme demands on the system. They require specialized chamber materials (like quartz), sophisticated heating elements, and can limit the types of substrates that can be used without damage.

Throughput vs. Uniformity

A system designed for high throughput, such as a batch furnace that processes many substrates at once, may struggle to achieve the same level of film uniformity as a single-substrate reactor. There is often a trade-off between the quantity of output and the quality of each individual piece.

Safety vs. Cost

The toxicity and reactivity of the precursor gases dictate the required level of safety engineering. Highly toxic gases like silane or phosphine demand more sophisticated, and therefore more expensive, gas handling cabinets, leak detectors, and exhaust abatement systems.

Making the Right Choice for Your Goal

The ideal CVD system configuration depends entirely on its intended purpose. Consider your primary objective to determine where to focus your requirements.

- If your primary focus is research and development: Prioritize a flexible, modular system with precise, wide-ranging control over temperature, pressure, and gas flows.

- If your primary focus is high-volume manufacturing: Prioritize automation, high throughput, reliability, and robust process control to ensure wafer-to-wafer repeatability.

- If your primary focus is working with hazardous materials: Prioritize safety, including sealed gas cabinets, extensive monitoring, and a highly effective exhaust abatement system.

- If your primary focus is coating temperature-sensitive substrates: Prioritize a lower-temperature system, such as a Plasma-Enhanced CVD (PECVD) reactor, which uses plasma instead of high heat to drive the reaction.

Ultimately, a CVD system is a purpose-built instrument where each component works in concert to create a precise and repeatable chemical environment.

Summary Table:

| Component | Primary Function | Key Subsystems |

|---|---|---|

| Gas Delivery System | Precise precursor delivery | MFCs, vaporizers, bubblers |

| Reaction Chamber | Thin film deposition | Substrate holder, heating elements |

| Vacuum System | Pressure control | Pumps, throttle valves |

| Energy Source | Drive chemical reactions | Heaters, RF plasma, lamps |

| Exhaust System | Safe byproduct removal | Scrubbers, abatement units |

Ready to optimize your thin film deposition process? KINTEK specializes in laboratory equipment and consumables for CVD applications. Whether you need a complete system for R&D flexibility or a high-throughput manufacturing solution, our expertise ensures you get the right configuration for your specific substrates and materials. Contact our experts today to discuss how we can enhance your lab's capabilities with precision CVD equipment.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- How is diamond coating done? A Guide to CVD Methods for Superior Performance

- What is organic thin film? A Guide to Engineered Molecular Layers for Advanced Tech

- What are the advantages of physical vapour deposition? Superior, Durable Coatings for Your Components

- Can gold be sputtered? Unlock Superior Thin-Film Performance for Your Applications

- What is a physical vapor deposition process? A Guide to High-Performance Thin Film Coatings

- What are the parameters of the CVD process? Master Thin Film Deposition for Your Lab

- What is low pressure chemical Vapour deposition? Achieve Superior Thin Film Uniformity

- What is the process of deposition precipitation? A Guide to Thin Film Deposition Fundamentals