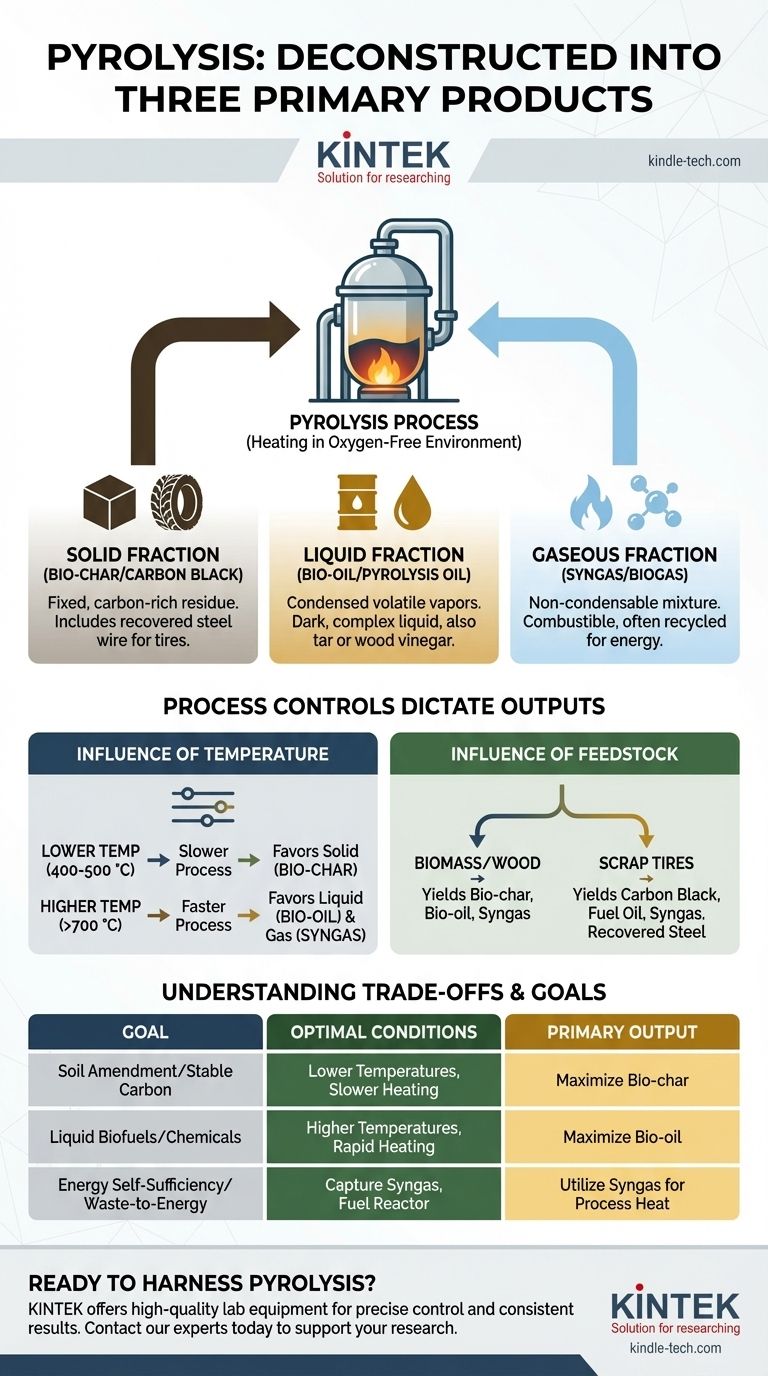

At its core, pyrolysis deconstructs a material into three primary product categories. The process involves heating a substance like biomass or tires to high temperatures in an oxygen-free environment, causing it to break down into a solid fraction (bio-char), a liquid fraction (bio-oil), and a gaseous fraction (syngas). The exact composition and yield of these products are not fixed; they are determined by the input material and the specific process conditions used.

Pyrolysis is best understood not as a single-output process, but as a controlled conversion technology. It transforms a single feedstock into three distinct and valuable product streams, with the final proportions of solid, liquid, and gas being deliberately controlled, primarily by temperature.

The Three Pillars of Pyrolysis Output

Every pyrolysis reaction yields products in three distinct physical states. The names may vary based on the input material, but the categories remain constant.

The Solid Fraction: Bio-char

The solid residue left after the volatile components have been driven off is a fixed, carbon-rich material.

This product is commonly called bio-char or biocoal when derived from biomass. When pyrolyzing tires, this solid is known as carbon black and the process also recovers the internal steel wire.

The Liquid Fraction: Bio-oil

As the material heats up, volatile gases are released. When these vapors are cooled and condensed, they form a dark, complex liquid.

This liquid is referred to as bio-oil, pyrolysis oil, or sometimes tar. When wood is the feedstock, a portion of this liquid condensate is also known as wood vinegar.

The Gaseous Fraction: Syngas

Not all the gases produced during pyrolysis will condense into a liquid. This remaining stream is a mixture of combustible gases.

This product is called syngas (synthesis gas) or biogas. It is often captured and recycled to provide the heat needed to power the pyrolysis reactor, making the process more energy-efficient.

How Process Conditions Dictate the Products

You cannot maximize the output of all three fractions simultaneously. The operator controls the outcome by manipulating two key variables: the process temperature and the input material.

The Role of Temperature

Temperature is the primary lever for determining the product yields.

Slower pyrolysis at lower temperatures, typically 400–500 °C, minimizes gas production and favors the creation of the solid bio-char.

Faster pyrolysis at higher temperatures, often above 700 °C, cracks the molecules more aggressively, favoring the production of liquid (bio-oil) and gaseous (syngas) fuels.

The Influence of Feedstock

The initial material being processed has a significant impact on the final products.

Pyrolysis of biomass or wood yields the standard trio of biochar, bio-oil, and syngas.

In contrast, pyrolyzing scrap tires yields carbon black, a petroleum-like fuel oil, syngas, and recovered steel—a fundamentally different set of outputs tailored to that specific waste stream.

Understanding the Trade-offs

The flexibility of pyrolysis is also its main complexity. The process must be engineered and fine-tuned to meet a specific goal, as optimizing for one product comes at the expense of others.

Balancing Yields for a Specific Goal

There is no single "best" way to run a pyrolysis system. The ideal conditions are entirely dependent on the desired end-product.

A facility aiming to produce agricultural biochar will operate at lower temperatures to maximize solid yield. Conversely, a plant designed to create liquid biofuel will use higher temperatures and rapid heating to maximize the bio-oil fraction.

The Challenge of Product Consistency

The chemical composition of bio-oil and other products can be complex and variable. Minor fluctuations in feedstock moisture or process temperature can alter the final output.

This requires robust process controls to ensure a consistent and marketable product, whether it's fuel, carbon, or chemical precursors.

Matching Pyrolysis Output to Your Goal

To apply pyrolysis effectively, you must first define your primary objective. The process parameters are then set to achieve that specific outcome.

- If your primary focus is creating a solid soil amendment or stable carbon: Operate at lower temperatures (400-500°C) with slower heating rates to maximize your bio-char yield.

- If your primary focus is producing liquid biofuels or chemical feedstocks: Use higher temperatures (>700°C) and rapid heating to favor the thermal cracking that produces bio-oil.

- If your primary focus is energy self-sufficiency or waste-to-energy: Capture the resulting syngas to fuel the reactor, significantly reducing the external energy required to run the process.

Understanding that you can control these outputs is the first step toward harnessing pyrolysis for your specific application.

Summary Table:

| Product Fraction | Common Name(s) | Primary Feedstock Example | Key Characteristic |

|---|---|---|---|

| Solid | Bio-char, Carbon Black | Biomass, Tires | Carbon-rich residue |

| Liquid | Bio-oil, Pyrolysis Oil | Biomass, Tires | Condensed volatile vapors |

| Gas | Syngas, Biogas | Biomass, Tires | Non-condensable combustible gases |

Ready to harness the power of pyrolysis for your laboratory or pilot plant? KINTEK specializes in high-quality lab equipment and consumables for pyrolysis research and development. Whether you're optimizing bio-char production, analyzing bio-oil composition, or scaling up syngas capture, our reliable solutions help you achieve precise control and consistent results. Contact our experts today to discuss how we can support your specific pyrolysis application and accelerate your project's success.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds