At its core, pyrolysis is a thermochemical process that decomposes biomass in an oxygen-starved environment. The methods for producing charcoal and biochar are primarily differentiated by two factors: the rate at which the biomass is heated and the amount of time it is kept at peak temperature. These variables directly control whether the final output is maximized for solid char, liquid bio-oil, or combustible gas.

The fundamental choice in pyrolysis is a trade-off between solid and liquid products. Slow pyrolysis is the established method for maximizing the yield of solid charcoal and biochar, while fast pyrolysis is specifically designed to maximize the production of liquid bio-oil.

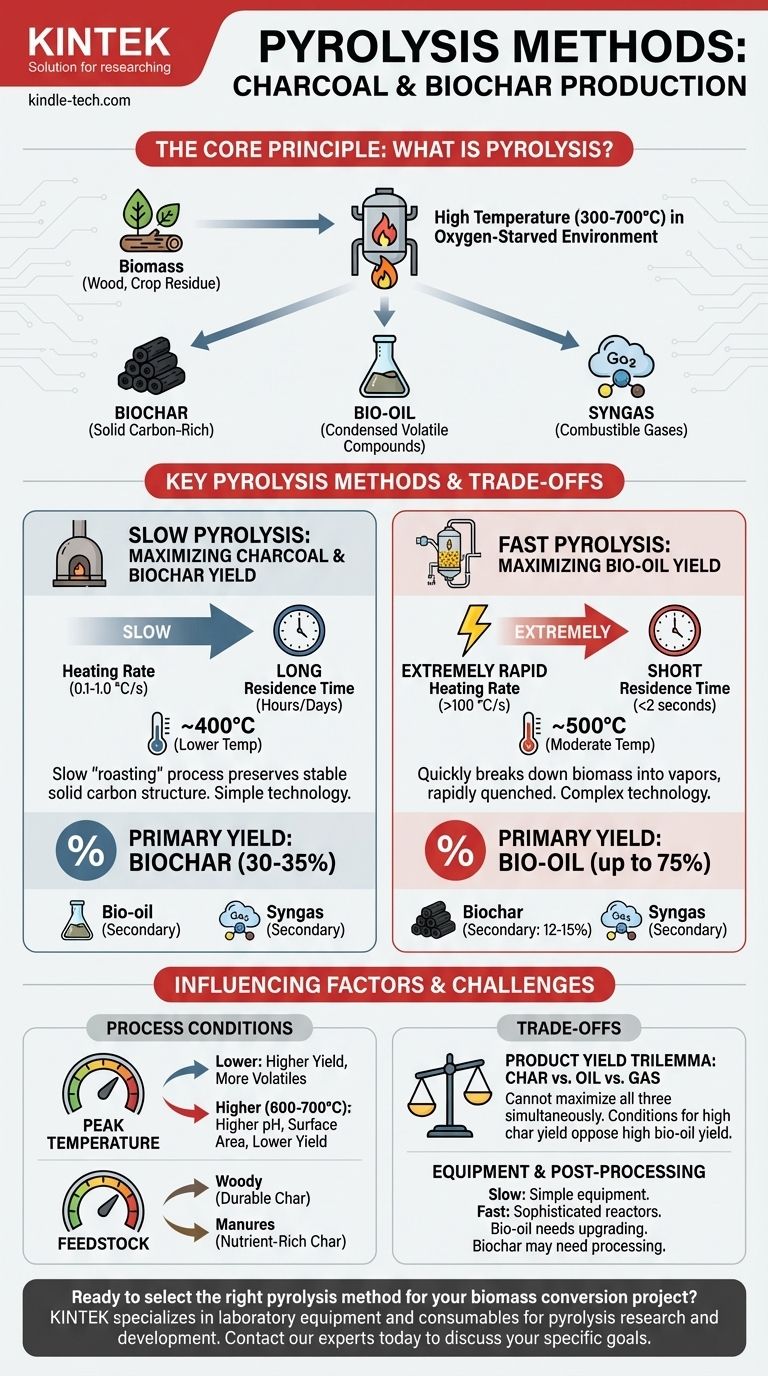

The Core Principle: What is Pyrolysis?

Pyrolysis is essentially "cooking" organic material, like wood or crop residue, at high temperatures (typically 300-700°C) without oxygen.

Because there is no oxygen, the material doesn't combust. Instead, it breaks down into three primary products:

- Biochar: The solid, carbon-rich charcoal.

- Bio-oil: A liquid mixture of condensed volatile compounds.

- Syngas: A mix of non-condensable, combustible gases like hydrogen, carbon monoxide, and methane.

The specific pyrolysis method you choose determines the ratio of these three outputs.

Key Pyrolysis Methods Defined

The primary methods are categorized as slow or fast, with intermediate variations existing between them. The name refers to the heating rate and residence time of the biomass in the reactor.

Slow Pyrolysis: Maximizing Charcoal & Biochar Yield

This is the traditional method for making charcoal and is the superior choice when your goal is to maximize the solid product.

Its defining characteristics are a slow heating rate (0.1-1.0 °C per second) and a long residence time for the material in the reactor, often lasting several hours or even days. The process typically occurs at lower temperatures, around 400°C.

This slow "roasting" process allows most of the volatile components to escape gradually while preserving a stable, carbon-rich solid structure. This method reliably yields the most biochar, often around 30-35% by weight.

Fast Pyrolysis: Maximizing Bio-oil Yield

This method is the polar opposite of slow pyrolysis and is used when the desired primary product is liquid fuel, not solid char.

It is defined by an extremely rapid heating rate (over 100 °C per second) and a very short residence time for the hot vapors (less than 2 seconds). The biomass is quickly heated to a moderate temperature (~500°C) to break it down into vapors, which are then rapidly cooled (quenched) to form liquid bio-oil.

Fast pyrolysis maximizes bio-oil yield (up to 75%) at the expense of biochar, which is typically a secondary product with yields around just 12-15%.

How Process Conditions Shape Your Biochar

The "method" is only part of the story. The final characteristics of your biochar—its pH, surface area, and stability—are controlled by specific process parameters. This is why biochar is not a single, uniform product.

The Role of Temperature

Peak temperature is arguably the most critical variable. Lower temperatures (e.g., 400°C) produce higher biochar yields but with more residual volatile matter. Higher temperatures (e.g., 600-700°C) produce a more "pure" carbon char with a higher pH and greater BET surface area, but the overall yield will be lower.

The Influence of Feedstock

The starting material fundamentally shapes the final product. Woody biomass tends to produce a durable, high-carbon char. Manures and biosolids create a char that is lower in carbon but much richer in nutrients like phosphorus and potassium.

Understanding the Trade-offs

Choosing a pyrolysis method involves balancing competing priorities. There is no single "best" method; there is only the best method for a specific goal.

The Product Yield Trilemma: Char vs. Oil vs. Gas

You cannot maximize all three outputs simultaneously. The conditions that favor high char yield (slow heating, long residence time) are precisely the opposite of what is needed for high bio-oil yield (fast heating, short residence time). You must decide which product stream is your priority.

Equipment Complexity and Cost

Slow pyrolysis can be performed with relatively simple technology, such as basic kilns or retort systems. Fast pyrolysis, however, requires sophisticated and expensive reactors (like fluidized bed or ablative reactors) to achieve the precise control over heating rates and residence times needed to maximize oil yield.

Post-Processing Requirements

The products often require further processing. Bio-oil from fast pyrolysis is acidic and unstable, typically requiring significant and costly hydroprocessing or upgrading to be used as a drop-in fuel. Biochar may require grinding, pelletizing, or "charging" with nutrients before it is suitable for agricultural use.

Selecting the Right Method for Your Goal

Your intended application should be the sole driver of your decision.

- If your primary focus is maximizing charcoal or soil-amendment biochar yield: Choose slow pyrolysis for its high solid product output, process stability, and simpler technology.

- If your primary focus is producing liquid biofuels (bio-oil): Choose fast pyrolysis, as it is specifically engineered to maximize the liquid fraction from biomass.

- If your primary focus is creating a biochar with specific properties (e.g., high porosity for filtration): Pay close attention to peak temperature and feedstock selection, as these parameters often have a greater impact on char quality than the method itself.

Ultimately, aligning the pyrolysis process with your desired end-product is the key to a successful outcome.

Summary Table:

| Method | Heating Rate | Residence Time | Peak Temperature | Primary Product Yield |

|---|---|---|---|---|

| Slow Pyrolysis | 0.1-1.0 °C/s | Long (Hours/Days) | ~400°C | Biochar (30-35%) |

| Fast Pyrolysis | >100 °C/s | Short (<2 seconds) | ~500°C | Bio-oil (up to 75%) |

Ready to select the right pyrolysis method for your biomass conversion project? KINTEK specializes in laboratory equipment and consumables for pyrolysis research and development. Whether you are optimizing for biochar yield or bio-oil production, our reactors and analytical tools provide the precision and control you need. Contact our experts today to discuss how we can support your laboratory's specific pyrolysis and biochar production goals.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the mechanism of pyrolysis? Unlock the Power of Thermal Decomposition Without Oxygen

- What is the effect of pyrolysis temperature on biochar properties? Mastering the Yield vs. Quality Trade-off

- What is the purpose of the rotary kiln? A Guide to Continuous High-Temperature Processing

- What biomass is used to make biochar? The Ultimate Guide to Choosing the Right Feedstock

- What temperature is needed for pyrolysis of plastic? Unlock the Right Heat for Your Desired Output

- Can reactors be used for the pyrolysis of plastic waste? The Core Technology Explained

- What is the theory of pyrolysis? A Guide to Thermal Decomposition for Waste and Energy Solutions

- What is the structure of a rotary kiln? A Detailed Breakdown of Its Core Components