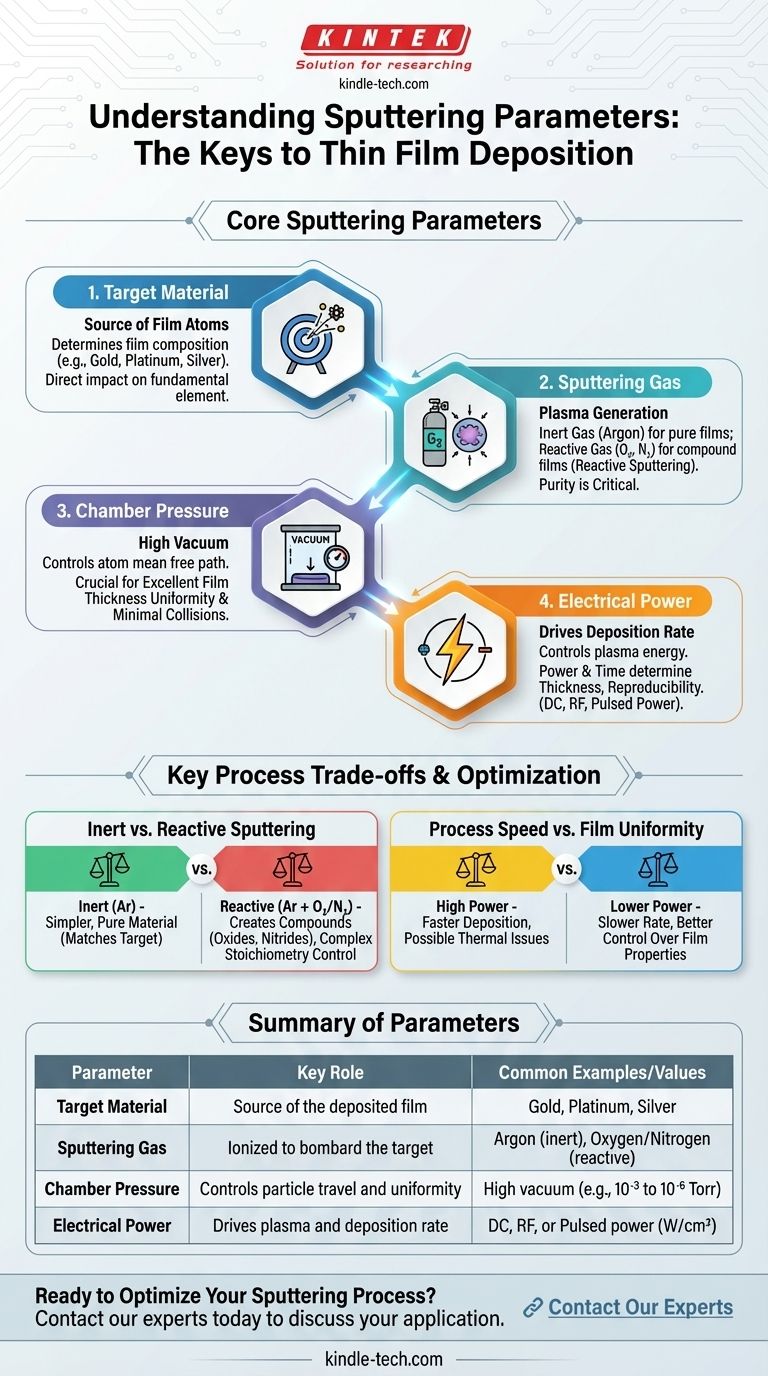

At its core, the sputtering process is governed by four primary parameters: the target material, the sputtering gas, the chamber pressure (or vacuum level), and the electrical power applied. These variables are manipulated in concert to eject atoms from a source material and deposit them as a highly uniform and adhesive thin film onto a substrate.

Mastering sputtering is an exercise in precise environmental control. The choice of each parameter is not made in isolation; together, they form a system of interdependent levers that dictate the final film's composition, structure, and quality.

The Core Components: Target and Substrate

The physical materials involved are the starting point for any sputtering process. The target is the source of the film, and the substrate is its destination.

The Target Material

The target material is the source of the atoms that will form the thin film. This is the material you intend to deposit.

Common examples of target materials include pure metals like gold, platinum, and silver. The choice of target directly determines the fundamental element being deposited.

The Substrate

The substrate is the object onto which the sputtered atoms condense to form the thin film. While the target is consumed, the substrate is coated.

The interaction between the sputtered atoms and the substrate surface is what leads to one of sputtering's key benefits: strong adhesion of the resulting film.

The Sputtering Environment: Gas and Pressure

The atmosphere inside the sputtering chamber is not empty; it is a carefully controlled, low-pressure gas environment critical to the process.

Sputtering Gas Composition

The gas introduced into the chamber is ionized to create the plasma that bombards the target. The type of gas used is a critical parameter.

An inert gas, most commonly argon (Ar), is used for standard physical sputtering. Argon ions are heavy enough to dislodge target atoms but are chemically non-reactive, ensuring the deposited film maintains the pure composition of the target.

Reactive gases, such as oxygen (O₂) or nitrogen (N₂), are introduced intentionally to create compound films. This process, known as reactive sputtering, causes the sputtered metal atoms to react with the gas on their way to the substrate, forming oxides, nitrides, or oxynitrides.

Gas Purity and Flow

The purity of the gas is paramount. The sputtering gas must be exceptionally clean and dry before entering the chamber.

Any impurities, such as moisture or other gases, can become incorporated into the film, altering its chemical composition and degrading its performance.

Chamber Pressure and Vacuum

Before introducing the sputtering gas, the chamber must be evacuated to a high vacuum. This removes ambient air and contaminants.

This low-pressure environment is crucial for allowing the sputtered atoms to travel from the target to the substrate with minimal collisions, a key factor for achieving excellent film thickness uniformity.

The Driving Force: Power and Plasma Generation

Electrical energy is what drives the entire process, creating the plasma and controlling the rate of deposition.

The Role of High Voltage

A high voltage is applied between the target (which acts as a cathode) and an anode. This strong electric field accelerates electrons and initiates the creation of the plasma.

The voltage creates the conditions necessary to ionize the sputtering gas atoms, turning them into the positively charged projectiles that will strike the negatively charged target.

The Function of Magnetic Fields

In magnetron sputtering, magnet arrays are placed behind the target. These magnets generate a magnetic field that traps electrons near the target surface.

This trapping effect dramatically increases the probability of electrons colliding with and ionizing the gas atoms, making the plasma generation much more efficient.

Controlling Deposition with Time and Power

The rate of deposition is directly controlled by the amount of power applied to the target and the duration of the process.

Increasing the power results in more ions hitting the target with greater energy, ejecting more atoms and increasing the deposition rate. This time and power controllability is what allows for high reproducibility and precise control over film thickness.

Understanding Key Process Trade-offs

Choosing the right parameters involves balancing competing factors to achieve the desired outcome.

Inert vs. Reactive Sputtering

The most fundamental choice is between depositing a pure material or a compound. Using an inert gas like argon is simpler and ensures the film's composition matches the target.

Opting for reactive sputtering allows for the creation of valuable compounds like ceramic oxides and nitrides, but it adds complexity. You must carefully control the gas mixture to achieve the correct chemical stoichiometry in the final film.

The Challenge of Contamination

The need for high vacuum and pure gas is a constant operational challenge. Achieving and maintaining these conditions requires robust equipment and careful procedures.

Any failure, such as a small leak in the chamber or a contaminated gas line, will directly impact the quality and purity of the deposited film, potentially rendering it useless.

Process Speed vs. Film Uniformity

While higher power increases deposition speed, it can also affect film properties. Extremely high power levels can generate excessive heat or alter the energy of the sputtered particles.

A balance must be found between a commercially viable deposition rate and the energy conditions that produce a film with the desired density, stress, and step coverage.

Matching Parameters to Your Deposition Goal

Your specific objective dictates how you prioritize and configure these parameters.

- If your primary focus is depositing a pure metal film: Prioritize a high-purity inert gas like argon and maintain the highest possible vacuum to prevent oxidation or contamination.

- If your primary focus is creating a compound film (e.g., a nitride): Utilize reactive sputtering by introducing a precisely controlled flow of reactive gas (like nitrogen) alongside your inert gas.

- If your primary focus is precise film thickness: Calibrate and meticulously control the applied power and deposition time, as these variables have the most direct impact on the amount of material deposited.

- If your primary focus is high deposition efficiency: Employ magnetron sputtering, as the use of magnetic fields significantly enhances the ionization of the sputtering gas, leading to a more robust plasma and a faster process.

Ultimately, mastering the interplay of these parameters empowers you to engineer thin films with exacting and repeatable characteristics.

Summary Table:

| Parameter | Key Role | Common Examples/Values |

|---|---|---|

| Target Material | Source of the deposited film | Gold, Platinum, Silver |

| Sputtering Gas | Ionized to bombard the target | Argon (inert), Oxygen/Nitrogen (reactive) |

| Chamber Pressure | Controls particle travel and uniformity | High vacuum (e.g., 10^-3 to 10^-6 Torr) |

| Electrical Power | Drives plasma and deposition rate | DC, RF, or Pulsed power (W/cm²) |

Ready to Optimize Your Sputtering Process?

Achieving precise control over target material, gas composition, pressure, and power is the key to high-quality, uniform thin films. KINTEK specializes in providing the high-purity lab equipment and consumables—including sputtering targets, gas handling systems, and vacuum components—that your laboratory needs for reliable and repeatable deposition results.

Contact our experts today to discuss how we can support your specific thin film application and help you master your sputtering parameters.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the temperature of PECVD deposition? Achieve High-Quality Films at Low Temperatures

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the drawbacks of PECVD? Understanding the Trade-offs of Low-Temperature Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition